Just trying to find some info on building my own fuel tanks for my truck, not sure if someone on here has done a step by step on how to build one yet.(links would be great

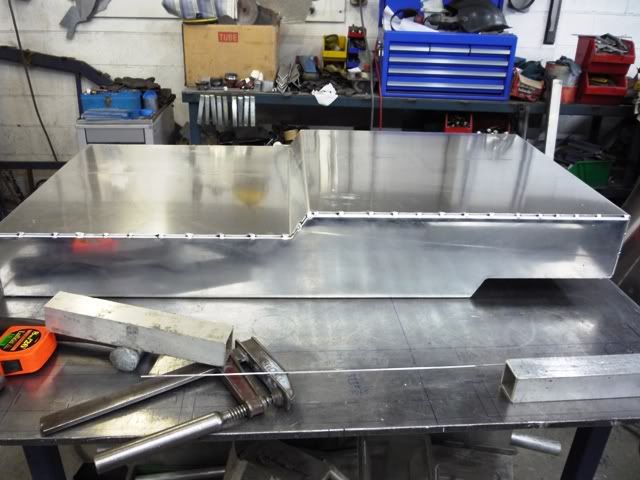

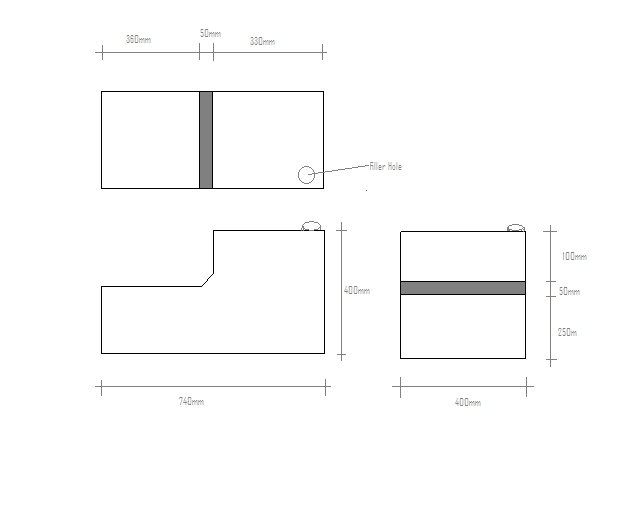

Will be building to hold diesel, going into a GQ. My idea is to run a larger main tank to fill in the void areas where the standard one sits, & then have that gravity fed into an auxilury tank on the passenger side(instead of the drivers side) so I don't constantly have the fat bastard in the drivers seat and the 80kg or so of fuel on the same side too. Due to the cab being chopped I can take advantage of the extra room for more tank space too.

I would ideally like to run two aux tanks either side of the rear tail shaft, but can't come up with a way to plumb the exhaust out the back. This way I could use the space from the original tank for the spare tyre instead... leaving more tray space. If anyone can give me a great idea on how to do this would be great too.(I have a V8 and the exhaust currently crosses over just behind the rear transfer output flange)

Things I need to know are....

1: What material?? (I was thinking 3mm steel top & sides with 4mm bottom for strength)

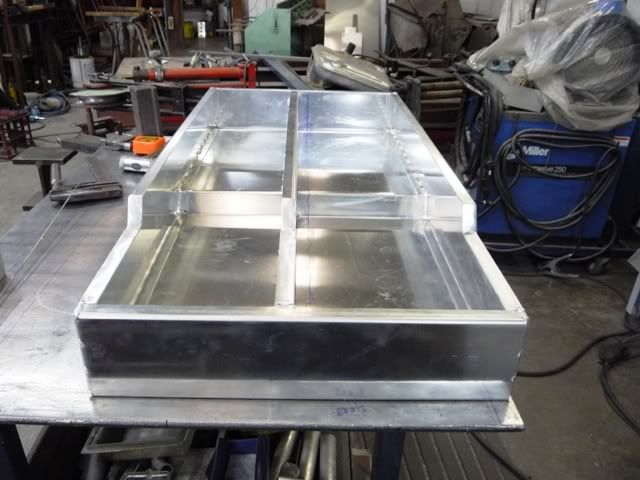

2: Baffles?? How to construct??

3: How much clearence do you give between the tank and chassis for flex??

4: What type of paint do you coat the inside with to protect against rusting without peeling off/effecting the diesel?? (I know you dont have to but would prefer to)

Will prob think of some other things later but that should get me started on things to buy for me to have a go over the chrissy break.

Cheers