RED60 wrote:Generally speaking, bolts only have about 1/2 the strength in shear that they do in tension. Just keep that in mind. Having said that, if you can somehow "hook" your winch cradle around your chassis so the bolts are only holding it in position that would be good. Have fun

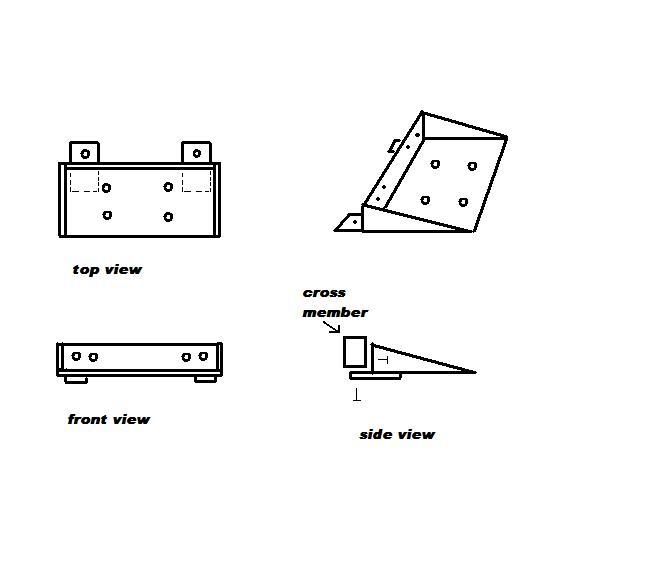

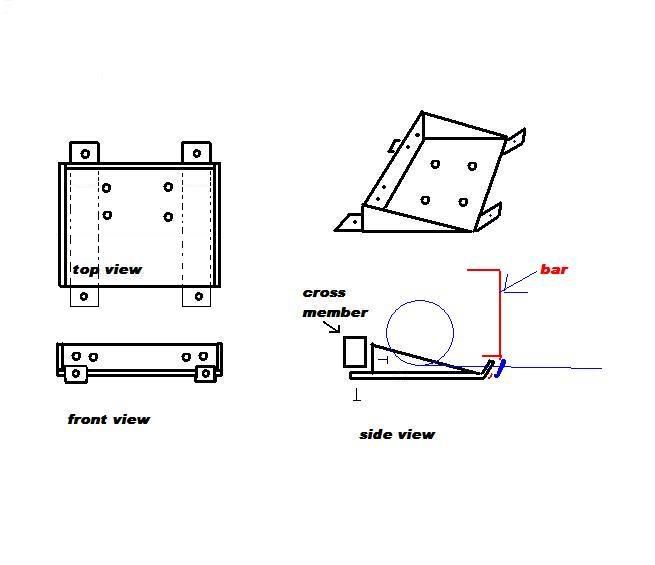

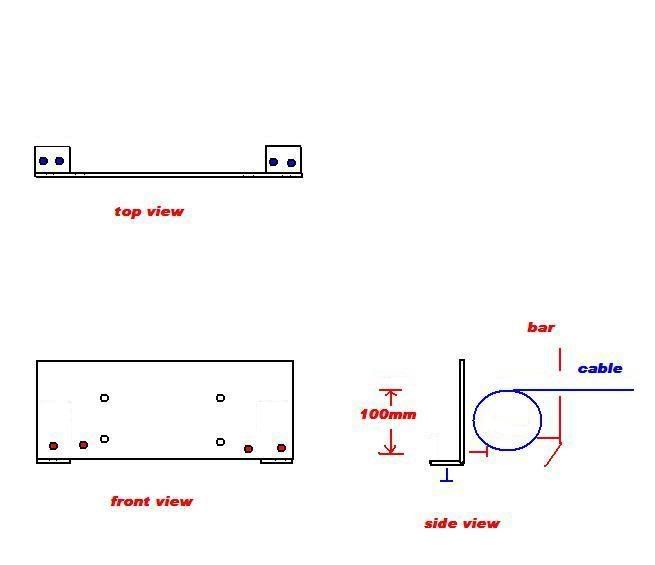

yeah makes sence, I was origionally thinking of mounting the winch to a flat plate across the cross member, but all the pics i found on line showed it set flat like the design above.

no space to hook around the chassis.

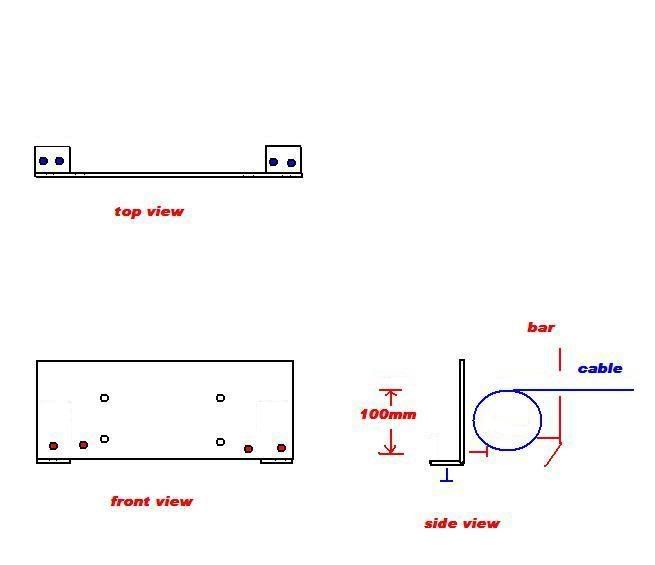

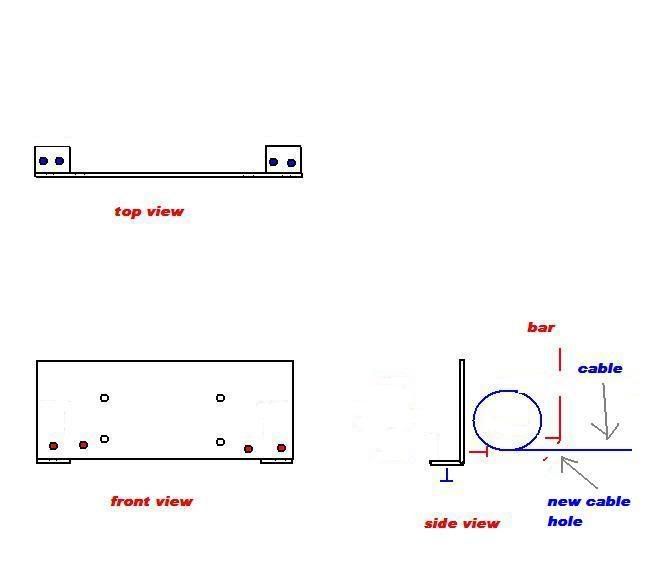

is a design like this better? as its also less work to make.

My only concerns with this are that with where the current cable hole is cut into the bar the cable needs to wind on at the top of the winch which will create alot more load/torque through the bolts at the bottom.

ie 4250 kg or 42500 N about a point 0.1m away will be 4250Nm. will the 4 bolts / cross member deal with that? and is my maths correct or at least close enough. I realise i havent take the bolts under the cross member into account.

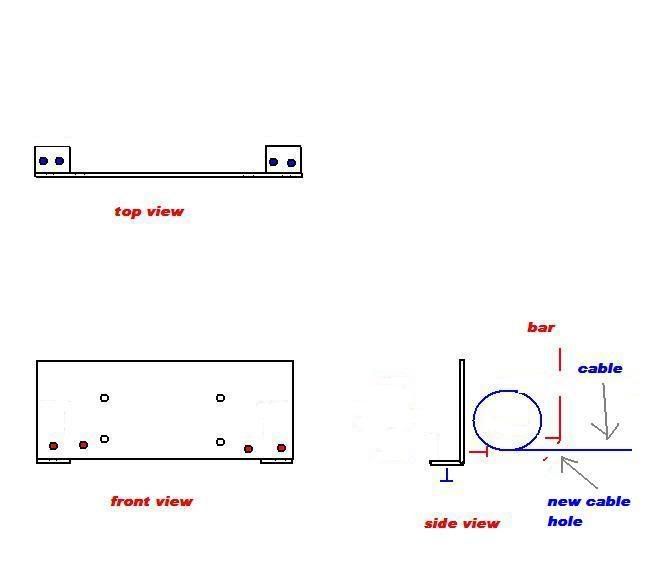

another option is to cut a new cable hole lower in the bottom part of the bar.

then the bolts are simply under tension which should be alot stronger.

would the plate bow out in the middle? or is it ok as the winch bolts on 1/3 of the way in from each side.

*there's a rock, drive over it :) there's a bigger rock, drive over it :twisted: there's an even bigger rock, oops broke it :oops: Upgrade broken bit :bad-words:

Goto *