Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Triton Balljoints wearing quickly

Moderator: -Scott-

Triton Balljoints wearing quickly

Hi guys.

I had all 4 suspension ball joints replaced in my 2002 triton 14 months ago, along with a few other bushes. After only a couple of months the lower driver's side ball joint began to creak again. It was returned and replaced under warranty. It was replaced again a couple of times after about 3 or 4 months each time.

Now 32000 km after the initial suspension job there is quite a bit of clunking coming from what I am sure is several of the ball joints. They are kept lubed with log book services.

Does this sound unusual for the life span of ball joints? I am expecting to have to replace them again soon, and it's not cheap.

I should also mention that the steering stoppers have been adjusted in, to improve the turning circle on the poor thing. Would this have anything to do with excessive wear?

Brad.

I had all 4 suspension ball joints replaced in my 2002 triton 14 months ago, along with a few other bushes. After only a couple of months the lower driver's side ball joint began to creak again. It was returned and replaced under warranty. It was replaced again a couple of times after about 3 or 4 months each time.

Now 32000 km after the initial suspension job there is quite a bit of clunking coming from what I am sure is several of the ball joints. They are kept lubed with log book services.

Does this sound unusual for the life span of ball joints? I am expecting to have to replace them again soon, and it's not cheap.

I should also mention that the steering stoppers have been adjusted in, to improve the turning circle on the poor thing. Would this have anything to do with excessive wear?

Brad.

2002 Turbo Diesel Dual Cab Triton

I'm running 31x10.5 Nankang ATs on 15'' sunnies.

The top ball joints were genuine and cost 120 or 140.

The problem one in the bottom, they first put a non-greasable one in, then a greasable one, then the grease nipple fell out when I went to grease it one day. So I went back and they had to grind the housing out to refit the grease nipple because it never fit in the first place. Then that one died. Then they fit another non-greasable one, and told me if it chewed another one, that they'd have to "try something else" because it was something wrong with my car making them chew out!

Then they fit another non-greasable one, and told me if it chewed another one, that they'd have to "try something else" because it was something wrong with my car making them chew out!

I don't do that much fourbying in it, and hardly any mud or hard stuff.

The top ball joints were genuine and cost 120 or 140.

The problem one in the bottom, they first put a non-greasable one in, then a greasable one, then the grease nipple fell out when I went to grease it one day. So I went back and they had to grind the housing out to refit the grease nipple because it never fit in the first place. Then that one died.

I don't do that much fourbying in it, and hardly any mud or hard stuff.

2002 Turbo Diesel Dual Cab Triton

That was all by a suspension specialist who does suspension for all sorts of high performance cars apparently.

I've just started going to a new mechanic and they seem pretty cluey. I'll get them to have a close look at it next week when it goes in for a log book service.

I've just started going to a new mechanic and they seem pretty cluey. I'll get them to have a close look at it next week when it goes in for a log book service.

2002 Turbo Diesel Dual Cab Triton

Not in the way you'd like. For a 4wd, your rims should be "JJ" - safety beads on both rims, not just one.flylux wrote:The rim says on it 7J X15 02 6 YF ... if that helps

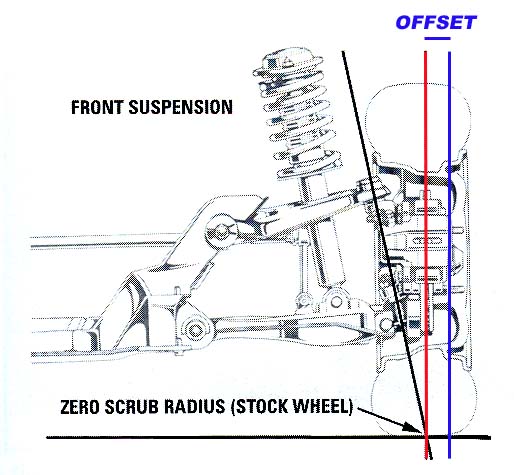

I'd guess you have 'Cruiser rims, which have probably altered your scrub radius by more than 30mm. If I was your original mechanic, I would point my finger at that, and deny all responsibility.flylux wrote:The tyre sticks about 40mm out of the guard,

(Ignoring the fact that a suspension specialist should have investigated, and discovered this after the first premature ball joint failure.)

My '03 Triton ball joints are 170,000km old and have been abused quite severely... Running a mix of standard and patrol offset 31-10.5-15's... Poor things been airborne on several occasions and done more corrugations than it cares to remember - no signs the ball joints are ready to give up yet...

I wish my lawn was EMO, then it would cut itself...

The gap you're looking at won't change as suspension cycles - the relationship between the wheel and the upper (and lower) balljoints remains fixed. The only time it will change significantly is if your bearings are VERY loose, or your rim buckles.flylux wrote:Scott,

Have a look at the clearance between the top ball joint and the rim. It only measures about 40mm. Would it make the wheel too close to that stationary part if I used a smaller offset?

If you've got 40mm in there you can change your offset by 25mm and still have 15mm clearance.

flylux wrote:yes, I understand that. So 25 mm could be enough to help prevent premature wear of the balljoints?

I have not had any experience with playing around with different wheel offsets and their consequences.

Typically, scrub radius is close to zero, as this minimises torque steer, low speed steering effort, and the effects of imbalanced braking force and/or traction.

While 25mm may not sound like much, it needs to be placed in context. If your scrub radius was originally 5mm, and you've added 25mm, that's a 500% increase.

Similarly with bearing loads. The original suspension design takes into account the centreline of the wheel, and the leverage effects on wheel bearings. Even if a 25mm change results in only a 50% increase in load on a bearing it's not good for longevity.

Please note that I can't guarantee that this is the source of your premature ball joint failure - but it is the first change I would make to try to solve the problem.

Hi there,

Regarding 'something else', I had a bit of noise (odd clunk not directly related to road undulations etc) coming from the front end of my 2001 MK. I temporarily removed the swaybar and the noise disappeared completely. I replaced outer swaybar bushes which appeared quite worn and while the noise did refrain for a while it has come back, though not as bad as previous. I intended to check the swaybar mounts to chassis next.

BTW, when I last had the front wheels off I did notice a very tiny bit of play (camber) that I shall monitor. Car has 91,000 km.

Hardy

Regarding 'something else', I had a bit of noise (odd clunk not directly related to road undulations etc) coming from the front end of my 2001 MK. I temporarily removed the swaybar and the noise disappeared completely. I replaced outer swaybar bushes which appeared quite worn and while the noise did refrain for a while it has come back, though not as bad as previous. I intended to check the swaybar mounts to chassis next.

BTW, when I last had the front wheels off I did notice a very tiny bit of play (camber) that I shall monitor. Car has 91,000 km.

Hardy

Yesterday I had the sway bar bushes replaced on my Challenger... magic !!!The socketty looseness I was feeling has gone... also was advised to keep tyre pressures up higher than the Mitsubishi recommended figures.

While they were at it they replaced the bolts on the base of the upper wishbones as the longer bolts give the ability to fit thicker shimsto correct wheel alignment... as I say the effect is magic.. should have had it done months ago.

I searched the Fulcrum suspension site.. they make Superpro brand poly bushes. They hafe parts to do steering idlers, upper wishbones and rear leaf springs for Challengers so presumably they have the same for Tritons too.

While they were at it they replaced the bolts on the base of the upper wishbones as the longer bolts give the ability to fit thicker shimsto correct wheel alignment... as I say the effect is magic.. should have had it done months ago.

I searched the Fulcrum suspension site.. they make Superpro brand poly bushes. They hafe parts to do steering idlers, upper wishbones and rear leaf springs for Challengers so presumably they have the same for Tritons too.

Who is online

Users browsing this forum: No registered users and 2 guests