well, plenty of Cookie on here that can weld...gomulletgo wrote:I've cracked one

Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

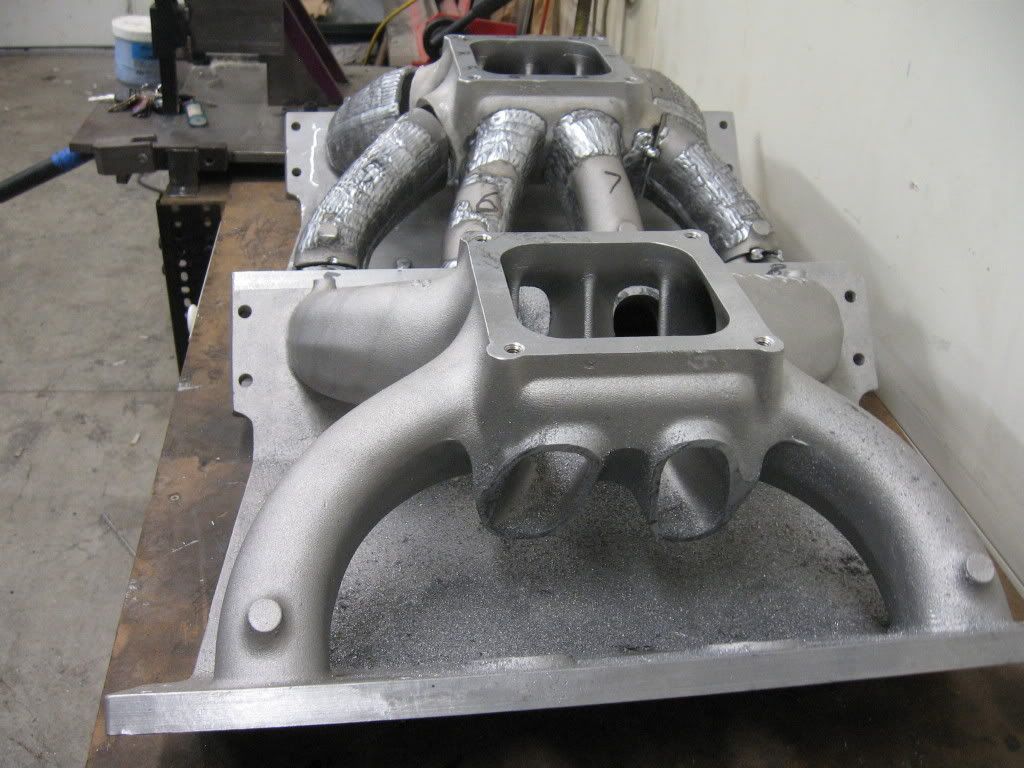

When fabrication becomes art.

Moderators: toaddog, TWISTY, V8Patrol, Moderators

I could call myself a welder, but I'd probably struggle to keep a straight face.brad-chevlux wrote:i still don't call myself a welder though.

A bloke I used to know was a boiler-maker. One day, in general conversation, another bloke, after finding out he's a boiler maker, commented "Oh yeah, I'm a welder too."

Well, did I hear all about it later. As far as I could tell, there is (was?)something like a caste system within the industry, and a "boiler maker" does not get called a "welder" - I think it was a mortal insult. As far as I could tell, the boiler maker does all the fabricating (for want of a better word - cut, shape, jig, tack etc) and the welder only welds.

I imagine that what we've seen here goes way beyond "boiler-maker" too.

You are spot on. Welder welds. Boily fabricates, but generally also gets lumped with the whole welding job as well. Boily is a step up from a welder.-Scott- wrote:I could call myself a welder, but I'd probably struggle to keep a straight face.brad-chevlux wrote:i still don't call myself a welder though.

A bloke I used to know was a boiler-maker. One day, in general conversation, another bloke, after finding out he's a boiler maker, commented "Oh yeah, I'm a welder too."

Well, did I hear all about it later. As far as I could tell, there is (was?)something like a caste system within the industry, and a "boiler maker" does not get called a "welder" - I think it was a mortal insult. As far as I could tell, the boiler maker does all the fabricating (for want of a better word - cut, shape, jig, tack etc) and the welder only welds.

I imagine that what we've seen here goes way beyond "boiler-maker" too.

marin

Rum injected

TD42T shorty... got some bolt on and some custom stuff.

Read about it [url=http://www.patrol4x4.com/forum/showthread.php?t=18848]here![/url]

TD42T shorty... got some bolt on and some custom stuff.

Read about it [url=http://www.patrol4x4.com/forum/showthread.php?t=18848]here![/url]

Re: When fabrication becomes art.

absolutelyawill4x4 wrote:

that ranks right up there with boobies to admire

thanks for posting those pics awill

Duck for cover! Here comes the knives.TUFF60 wrote:I will stand clear while someone throws the knives but, i think it looks like those welds were done by a Pulse Mig. Would explain the machine like consistency. Sexy either way.

I've read a few posts of his on a few forums and he says he rarely uses pulse and all his welding is Tig.

His background is from head and manifold porting and he then branched out into manifold design and manufacture.

His "machine like consistency" is exactly why I posted the pics, his welding control is simply amazing and believe me I'm not a guy who's easily impressed.

He also does a lot of modifying to cast aluminium manifolds as well and this stuff really freaks me out.

I'd like to see just how that last manifold turned out but I can't find it yet.

Enjoy:

We are Tig welders, gravity doesn't worry us.

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

Gday Andy i tell ya what that is pretty impressive as you i am not easily impressed by others welding and fab ability but that is something else.

I could probably get close but wow.

As for the Argon helium mix this is what i use on ally at work and it is much smoother even control heat that is quite hotter than with just argon it also leaves the weld much cleaner being a more pure gas. Those pics would be pretty much straight off the torch.

Oh by the way its Damo from over at fineweld mate not sure if ya would have realised

I could probably get close but wow.

As for the Argon helium mix this is what i use on ally at work and it is much smoother even control heat that is quite hotter than with just argon it also leaves the weld much cleaner being a more pure gas. Those pics would be pretty much straight off the torch.

Oh by the way its Damo from over at fineweld mate not sure if ya would have realised

have grinder will fit

www.4Bfabrications.com.au

www.4Bfabrications.com.au

Hi all...There are boilermaker marker offs and there are boilermaker welders,and then you have the guys who have pressure tickets that weld things like pressure vessels,pipes ect for things like petroleum,gas ect that get xrayed as much as 100% of buttwelds.In the boilermaking scene generally boilermaker welders are looked at as failed boilermakers that can only do general welding and basic boilermaking,but often wont boilermake by choice.The guys that actually do the highest end of welding are the guys welding exotic metals that are getting xrayed,They are always respected and are the highest money earners.These guys are the pinnacle of welders.-Scott- wrote:I could call myself a welder, but I'd probably struggle to keep a straight face.brad-chevlux wrote:i still don't call myself a welder though.

A bloke I used to know was a boiler-maker. One day, in general conversation, another bloke, after finding out he's a boiler maker, commented "Oh yeah, I'm a welder too."

Well, did I hear all about it later. As far as I could tell, there is (was?)something like a caste system within the industry, and a "boiler maker" does not get called a "welder" - I think it was a mortal insult. As far as I could tell, the boiler maker does all the fabricating (for want of a better word - cut, shape, jig, tack etc) and the welder only welds.

I imagine that what we've seen here goes way beyond "boiler-maker" too.

PEACE...

whats the trade name and how do ya get into it? this sorta thing is what i want to do, but apprenticeships only rarely come up for boilermaker/welders(global financial crisis aint a great time to look for an apprenticeship apparently...).mickbeny wrote:These guys are the pinnacle of welders.

[quote="Barnsey"]

Bronwyn Bishop does it for me.[/quote]

Bronwyn Bishop does it for me.[/quote]

Yeah Damo, I thought your username matched your number plate.UrbanRedneck wrote:Gday Andy i tell ya what that is pretty impressive as you i am not easily impressed by others welding and fab ability but that is something else.

I could probably get close but wow.

As for the Argon helium mix this is what i use on ally at work and it is much smoother even control heat that is quite hotter than with just argon it also leaves the weld much cleaner being a more pure gas. Those pics would be pretty much straight off the torch.

Oh by the way its Damo from over at fineweld mate not sure if ya would have realised

See if you can "acquire" a G size bottle of Helium so I can have a play will you?

We are Tig welders, gravity doesn't worry us.

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

Hi all...Macca81,You have to be a boilermaker first before you can get tickets,But just because you have tickets doesnt mean your good enough to weld cetain jobs.You best getting an apprenticeship with a company that does pipe and pressure vessel work,this way you will be working beside the elite welders and fabricators.Specialty welding isnt learnt over nite,It takes literally decades to be a very good welder.macca81 wrote:whats the trade name and how do ya get into it? this sorta thing is what i want to do, but apprenticeships only rarely come up for boilermaker/welders(global financial crisis aint a great time to look for an apprenticeship apparently...).mickbeny wrote:These guys are the pinnacle of welders.

PEACE...

Guys i am a sheety by trade and have no tickets as such but i do 100% xray petro chem pressure vessel work (stainless steel).

The way around this is there is a procedure supplied by the company then you get tested and checked by independent testers with which they do macro xray particle and destructive testing of your sample welds. After which if passed you can do the work but if you dont use it for certain amount of time you get retested.

Here is link to some of my work

http://s339.photobucket.com/albums/n473/R3DN3K_PATROL/

Sorry Andy only got the big bottle. We also use argon Co2 helium mix for our pulse mig runs on all the petro chem stuff.

The way around this is there is a procedure supplied by the company then you get tested and checked by independent testers with which they do macro xray particle and destructive testing of your sample welds. After which if passed you can do the work but if you dont use it for certain amount of time you get retested.

Here is link to some of my work

http://s339.photobucket.com/albums/n473/R3DN3K_PATROL/

Sorry Andy only got the big bottle. We also use argon Co2 helium mix for our pulse mig runs on all the petro chem stuff.

have grinder will fit

www.4Bfabrications.com.au

www.4Bfabrications.com.au

The helium in the mix assists greatly with edge wetting of the welds hence the seemlees transition of weld material to parent metal.UrbanRedneck wrote:Gday Andy i tell ya what that is pretty impressive as you i am not easily impressed by others welding and fab ability but that is something else.

I could probably get close but wow.

As for the Argon helium mix this is what i use on ally at work and it is much smoother even control heat that is quite hotter than with just argon it also leaves the weld much cleaner being a more pure gas. Those pics would be pretty much straight off the torch.

Oh by the way its Damo from over at fineweld mate not sure if ya would have realised

We use it for welding stainless with an AC MIG welder and it dramatically increases the machines capability to weld correctly, in fact it wont weld correctly without the Helium.

Oh, and boilermakers tolerance is 1/4" if they really try and give themselves a headache, welders work to parts of millimetres with ease

Cheers.

awill4x4 wrote:Dems fighting words StruthStruth wrote: Oh, and boilermakers tolerance is 1/4" if they really try and give themselves a headache, welders work to parts of millimetres with ease

Cheers.

Can't resist a dig at dem big dumb boilies out there, god love their little minds

Perfect example today, we have a boily works in our shop doin a job i normaly do ask me for a measurement was told twice it is on there i was told twice it wasnt walked over and pointed straight at it was told that it wasnt clear enough what it was. ONLY DRAWING ONLY MEASUREMENT ON PAGE AND HEADING SAID WHAT IT WAS.Struth wrote:awill4x4 wrote:Dems fighting words StruthStruth wrote: Oh, and boilermakers tolerance is 1/4" if they really try and give themselves a headache, welders work to parts of millimetres with ease

Cheers.Thought they might be

Can't resist a dig at dem big dumb boilies out there, god love their little minds

have grinder will fit

www.4Bfabrications.com.au

www.4Bfabrications.com.au

It's o b v i o u s y o u w e r e s p e a k i n g t o o f a s t f o r h i m

I like the fact the smallest hammer our boily has is somethign like a 12lb dead blow and he uses it for everything. including squaring up 25 x 25 ali box framing. and no he's not actually that precise with it. Sorry P R E C I S E. He was building an ali window screen/shade the other day with angles louvers and got to the last one to find it was 10mm out. He said to the boss it was out, boss said what do you want me to do, he asked what do we do to fix, boss said well why is it out, he thought for a minute and said must have stuffed up the spacings, boss said what do you expect me to do about it, he said don't know.

I like the fact the smallest hammer our boily has is somethign like a 12lb dead blow and he uses it for everything. including squaring up 25 x 25 ali box framing. and no he's not actually that precise with it. Sorry P R E C I S E. He was building an ali window screen/shade the other day with angles louvers and got to the last one to find it was 10mm out. He said to the boss it was out, boss said what do you want me to do, he asked what do we do to fix, boss said well why is it out, he thought for a minute and said must have stuffed up the spacings, boss said what do you expect me to do about it, he said don't know.

Being a sheetie in a small shop where you have no choice but to do everything from go to whoa (and preferring it that way) I'm not sure how you could find welding your design/fabrication out to completion boring.AFeral wrote:Not sure how you welders work to mm. Most of you are not good enough to fab and weld. That why they give that job to us boilermaker. Leaving you welders with the bit we find boring.

Couldn't agree more nothing like starting with nothing and finnishing the last weld and looking at what you created by yourself.fester2au wrote:Being a sheetie in a small shop where you have no choice but to do everything from go to whoa (and preferring it that way) I'm not sure how you could find welding your design/fabrication out to completion boring.AFeral wrote:Not sure how you welders work to mm. Most of you are not good enough to fab and weld. That why they give that job to us boilermaker. Leaving you welders with the bit we find boring.

Very satisfying.

have grinder will fit

www.4Bfabrications.com.au

www.4Bfabrications.com.au

He He ! Thought I would get a few bites from that comment. I've worked with welders that are not good enough to weld and fab, they just give them welder and are left alone. Others than can produce welds that look like the art else where on this thread. Same goes for boilermakers theres those that work to mm and those that work to inchs.

Anything is possible, it just comes down to time and money.

Ferals build www.outerlimits4x4.com/ftopic164570.php

Ferals build www.outerlimits4x4.com/ftopic164570.php

Ask him if he has papers a lot of people run around saying they are boiler makers after 10-20+ years of welding but don't have any papers to back up any of what they say, it's generally the people who you ask them to do a virtical upetc and they look dumb founded or just simply don't know what to do.fester2au wrote:It's o b v i o u s y o u w e r e s p e a k i n g t o o f a s t f o r h i m

I like the fact the smallest hammer our boily has is somethign like a 12lb dead blow and he uses it for everything. including squaring up 25 x 25 ali box framing. and no he's not actually that precise with it. Sorry P R E C I S E. He was building an ali window screen/shade the other day with angles louvers and got to the last one to find it was 10mm out. He said to the boss it was out, boss said what do you want me to do, he asked what do we do to fix, boss said well why is it out, he thought for a minute and said must have stuffed up the spacings, boss said what do you expect me to do about it, he said don't know.

Hi all...It is very satisfying to build and weld a job on your own,But in boilermaking most jobs are so big they take months/years of work with a team of boilermakers and welders on the one job.UrbanRedneck wrote:Couldn't agree more nothing like starting with nothing and finnishing the last weld and looking at what you created by yourself.fester2au wrote:Being a sheetie in a small shop where you have no choice but to do everything from go to whoa (and preferring it that way) I'm not sure how you could find welding your design/fabrication out to completion boring.AFeral wrote:Not sure how you welders work to mm. Most of you are not good enough to fab and weld. That why they give that job to us boilermaker. Leaving you welders with the bit we find boring.

Very satisfying.

PEACE...

Yep, and god look out if it isn't on the drawing.mickbeny wrote:UrbanRedneck wrote:Couldn't agree more nothing like starting with nothing and finnishing the last weld and looking at what you created by yourself.fester2au wrote:Being a sheetie in a small shop where you have no choice but to do everything from go to whoa (and preferring it that way) I'm not sure how you could find welding your design/fabrication out to completion boring.AFeral wrote:Not sure how you welders work to mm. Most of you are not good enough to fab and weld. That why they give that job to us boilermaker. Leaving you welders with the bit we find boring.

Very satisfying.

Hi all...It is very satisfying to build and weld a job on your own,But in boilermaking most jobs are so big they take months/years of work with a team of boilermakers and welders on the one job.

Who is online

Users browsing this forum: No registered users and 1 guest