Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Laminating Rear Lower Control Arms

Laminating Rear Lower Control Arms

Next Week Im Thinking Of Laminating My Rear Lower Control Arms On My GQ. I've Just Got A Few Questions:

- How Thick Are The Stock Lower Arms?

- Should I Use Flat Steel? (I Hear People Also Use Angle)

- What Dimensions?

- Should I Stitch Weld Them, Or Completly Weld Them? (Slowly)

Im Thinking Of Using 8mm x 25mm by Roughly How Ever long They Are

And Will Probally Stitch Weld It But Any Feedback And Ideas Would Be Helpful

- How Thick Are The Stock Lower Arms?

- Should I Use Flat Steel? (I Hear People Also Use Angle)

- What Dimensions?

- Should I Stitch Weld Them, Or Completly Weld Them? (Slowly)

Im Thinking Of Using 8mm x 25mm by Roughly How Ever long They Are

And Will Probally Stitch Weld It But Any Feedback And Ideas Would Be Helpful

Sure Could Go Some Side Boob Right Now

I've seen angle used and it was stitch welded. Thats all you need. Its only to stop them flexing and ultimately failing once bent. Be very careful though, the walls are not very thick and you can blow holes in them if you go too hot. I suggest picking up a set second hand and welding those. Then its just a change over job.

GU Patrol intercooled TD42T, lifted, Cheezy sliders, ARB air locker, beadlocked Claws, Warn winch

I sleeved mine with thicker walled mild steel pipe that has the inside diameter the same as the outside diameter of the originals.

Cut the originals in half and slid them in the new pipe, welded the ends and also drilled 4 evenly spaced 10mm holes in the new pipe and plug welded through to the originals.

Cut the originals in half and slid them in the new pipe, welded the ends and also drilled 4 evenly spaced 10mm holes in the new pipe and plug welded through to the originals.

GQ Patrol Wagon, 6 point roll cage

351 cleveland, CHI heads, solid cam, Funnelweb single plane, 750 HP DP

351 cleveland, CHI heads, solid cam, Funnelweb single plane, 750 HP DP

Here is a detailed way of sleeving from patrol4x4 which includes panhard bars.351ciofgrunt wrote:I sleeved mine with thicker walled mild steel pipe that has the inside diameter the same as the outside diameter of the originals.

Cut the originals in half and slid them in the new pipe, welded the ends and also drilled 4 evenly spaced 10mm holes in the new pipe and plug welded through to the originals.

http://www.patrol4x4.com/forum/showthread.php?t=29588

Its not cool, unless it's got boost :)

Bring them round of you want, will sort them out for you. Talk to ya bout them tomorrowGU-ish wrote:mite do it to mine as well, seems as one needs replacing cuz its bent

'89 Hilux Single Cab - 3RZ, 35" Kreepy Krawlers, 4.88's, F & R Air lockers, RUF, Longfields, TG Highsteer, Highmount and no money

Lamination

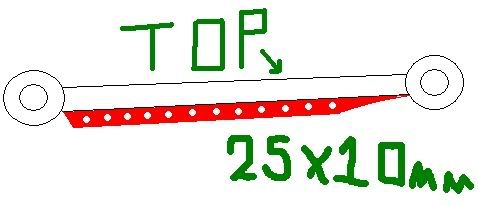

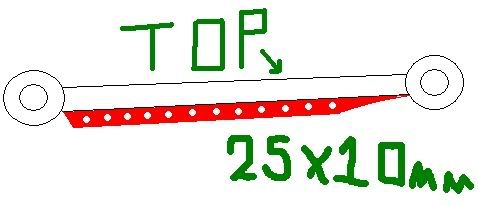

This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

Sure Could Go Some Side Boob Right Now

Re: Lamination

Speed holes, did you get the other bit drilled out and shaped?Dyls GQ wrote:This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

'89 Hilux Single Cab - 3RZ, 35" Kreepy Krawlers, 4.88's, F & R Air lockers, RUF, Longfields, TG Highsteer, Highmount and no money

Re: Lamination

Weiner wrote:Speed holes, did you get the other bit drilled out and shaped?Dyls GQ wrote:This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

Nah Had To Go See Shane....Gettin My Other Tire Tommoro

Sure Could Go Some Side Boob Right Now

Re: Lamination

Find out about the other CreepyDyls GQ wrote:Weiner wrote:Speed holes, did you get the other bit drilled out and shaped?Dyls GQ wrote:This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

Nah Had To Go See Shane....Gettin My Other Tire Tommoro

'89 Hilux Single Cab - 3RZ, 35" Kreepy Krawlers, 4.88's, F & R Air lockers, RUF, Longfields, TG Highsteer, Highmount and no money

Re: Lamination

I've just done mine but put the flat bar on the top - I think it will do more good on top because the the arms tend to bend upwards, if you hit a big rock and bend the bar over, it wont prevent the arms kinking up if that makes sense....Weiner wrote:Speed holes, did you get the other bit drilled out and shaped?Dyls GQ wrote:This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

Re: Lamination

with putting them on top.. do the mounts matter on the chassis end.... like will in hit on full flex?Mark2 wrote:I've just done mine but put the flat bar on the top - I think it will do more good on top because the the arms tend to bend upwards, if you hit a big rock and bend the bar over, it wont prevent the arms kinking up if that makes sense....Weiner wrote:Speed holes, did you get the other bit drilled out and shaped?Dyls GQ wrote:This Is What Im Doing Here:

10mm X 25mm With Holes Drilled Along For Absolutly No Reason Other Than The Fact It Looks Cool!!... The Front Its Angled To Stop Anything Smashing Againt A Vertical Surface (Alowing It To Act As A Slider)

I Will Post Up Photos Tomorro!

Sure Could Go Some Side Boob Right Now

Re: braces

Doin them on the weekend?Dyls GQ wrote:This Is What I Ended Up With

Basically I Learnt That Im Am Shit At Grinding And Drilling Holes!

Good Enough... Will Get Me By Till I Buy Adjustable Arms

Thought most adjustable arms are for the uppers?

'89 Hilux Single Cab - 3RZ, 35" Kreepy Krawlers, 4.88's, F & R Air lockers, RUF, Longfields, TG Highsteer, Highmount and no money

Re: Weiner

Dyls GQ wrote:If Their Just For Uppers Than Why Do They Make Lowers To??

Wrap Ya Mind Around That One

I Just Want Stronger Ones..May Aswell Get Adjustables

most using adjustable lowers have shortys and are trying to sort out pinion angles.

Best not to use them as lowers are subject to alot more forces than uppers and adjustable's threaded rod can be the weak link.

They are not welded yet, he said he used one but he went straight for the big hole, didn't do a pilot hahaGU-ish wrote:did ya use a centre punch first dylo?? and a smaller hole before the bigger one??

any pics of it welded on?

'89 Hilux Single Cab - 3RZ, 35" Kreepy Krawlers, 4.88's, F & R Air lockers, RUF, Longfields, TG Highsteer, Highmount and no money

Who is online

Users browsing this forum: No registered users and 1 guest