Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

options to widen rear of chassis rails

Moderators: toaddog, TWISTY, V8Patrol, Moderators

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

options to widen rear of chassis rails

Hi all

I've been trying to address the issue of the rear end of my truck flexing incredibly well and the front not at all. Notwithstanding coil rates, sway bars and radius arm bush binding, the reall issue seems to be that it's because the chassis rails at the rear (and therefore the coils) are substantially closer together than at the front so there's no leverage through the chassis to force the front to work and the rear end seems to pivot around the coils rather than getting any real compressive force from them.

I was discussing in Struth's thread about running a home-made currie anti rock sway bar but i'd rather address the real issue (not that i have anything against swaybars), so that i can look at x-linking the front or running a four link and still have a modicum of roll stability.

Now i've been given three options to do this.

1. Have the chassis narrowed slightly at the rear so i can run the coils outboard of the chassis rails

2. C-notch the chassis so i can run the coils under the rails like the mini-truckers do

or

3. Graft a chassis cut from the rear of an 80 series.

What are peoples' thoughts on all of these options? given that the tray is easily modified for all of these options and body work isn't really a problem.

Also an 80 series coil hats are only about 115mm wider than mine. Is this really likely to make that much of a difference? Currently i have standard 80 series width on the front (950mm centre of coil to centre of coil) and the rear is about 730mm centre to centre. Is a 100 series chassis wider again? Other than the sheer distance that the coils have to travel the further out you go (and the amount they would dislocate) is wider necessarily going to be wider? I mean theoretically i could get them as wide as the front but unless they're uber long coils they're going to dislocate like crazy.

I've been trying to address the issue of the rear end of my truck flexing incredibly well and the front not at all. Notwithstanding coil rates, sway bars and radius arm bush binding, the reall issue seems to be that it's because the chassis rails at the rear (and therefore the coils) are substantially closer together than at the front so there's no leverage through the chassis to force the front to work and the rear end seems to pivot around the coils rather than getting any real compressive force from them.

I was discussing in Struth's thread about running a home-made currie anti rock sway bar but i'd rather address the real issue (not that i have anything against swaybars), so that i can look at x-linking the front or running a four link and still have a modicum of roll stability.

Now i've been given three options to do this.

1. Have the chassis narrowed slightly at the rear so i can run the coils outboard of the chassis rails

2. C-notch the chassis so i can run the coils under the rails like the mini-truckers do

or

3. Graft a chassis cut from the rear of an 80 series.

What are peoples' thoughts on all of these options? given that the tray is easily modified for all of these options and body work isn't really a problem.

Also an 80 series coil hats are only about 115mm wider than mine. Is this really likely to make that much of a difference? Currently i have standard 80 series width on the front (950mm centre of coil to centre of coil) and the rear is about 730mm centre to centre. Is a 100 series chassis wider again? Other than the sheer distance that the coils have to travel the further out you go (and the amount they would dislocate) is wider necessarily going to be wider? I mean theoretically i could get them as wide as the front but unless they're uber long coils they're going to dislocate like crazy.

http://www.populationparty.org.au/

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

If it were me id use the 80 rear half for a few reasons.

Looks more like it was meant to be there.

You wont get a "c notch" complied and it will crack etc

There is 2 or 3 75's that have been coiled built around here over the last few years, all of them suffered the same issues as your truck. I dont think ive seen an 80 do the same (well to the same extreemes)

You would have to narrow the chassis a ridiculous amount to allow for coils on the outside of the chassis without scrubbing issues

Looks more like it was meant to be there.

You wont get a "c notch" complied and it will crack etc

There is 2 or 3 75's that have been coiled built around here over the last few years, all of them suffered the same issues as your truck. I dont think ive seen an 80 do the same (well to the same extreemes)

You would have to narrow the chassis a ridiculous amount to allow for coils on the outside of the chassis without scrubbing issues

1hd-fte 5 speed tiptronic 105 series

78 series troopy for work

gu ute play truck For sale

FTE 80 series sahara Sold

i think i have a problem

78 series troopy for work

gu ute play truck For sale

FTE 80 series sahara Sold

i think i have a problem

Banned

g'day milo, ive experienced the same problems as you , even with my front end xlinked,what ive come up with is the weight difference, theirs no weight over the rear so the back is just gonna flex like mad everytime , and also the radius arm setup front vs linked rear, if i was to do mine again id go linked front end, i might even go that way in the future, im going coilovers in the rear of mine soon so i can go stiffer spring rate and shock valving, only problem i can see with coils under the chassis rail is you'd need like 2" coils to sit the truck level , but you can imagine how much they'd drop out everytime. let me know what you think.

Re: options to widen rear of chassis rails

Option one is probably the best option, although I wouldn't "Narrow" it if you can get away just dove tail the rear like the photo shown.rockcrawler31 wrote:

Now i've been given three options to do this.

1. Have the chassis narrowed slightly at the rear so i can run the coils outboard of the chassis rails

2. C-notch the chassis so i can run the coils under the rails like the mini-truckers do

or

3. Graft a chassis cut from the rear of an 80 series.

However I wouldn't want the springs outboard of the chassis, you'll need crazy long springs to get reasonable articulation, one of the reasons an 80 flexes so well is the spread of the springs and shocks.

2 "C" Notching is almost impossible to get engineered and as has been mentioned will cause many more problems than it solves

3 Grafting a chassis isn't much different to Notching or narrowing, technically you are modifying the chassis which under LVM rules is a no- no.

If none of the above work, it'd probably be better/easier to put your body on an 80 series Chassis rather than grafting parts of it into yours. you'll get a well rounded package that way with the body you like

Last edited by Black Bull on Mon Apr 05, 2010 7:19 pm, edited 1 time in total.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Re: options to widen rear of chassis rails

Using an entire chassis is certainly an option but in the end is no less fabrication work given that i'll have to totally rejig all the body and engine mounts and then re-jig the front and rear mounts to suit my radius arm lengths.Black Bull wrote: 3 Grafting a chassis isn't much different to Notching or narrowing, technically you are modifying the chassis which under LVM rules is a no- no.

If none of the above work, it'd probably be better/easier to put your body on an 80 series Chassis rather than grafting parts of it into yours. you'll get a well rounded package that way with the body you like

If you follow some guidelines you can indeed modify a chassis, particularly in NSW. There have been plenty of chassis extensions done for the 6x6 vehicles so the same principles of joining an extended section would be applied i guess.

My feeling is that the weight is not an issue, in fact it's the other way around to what you have outlined. The forward weight bias would help to force the front to work and i've noted that when you ramp the car backwards so that there is a forwards weight transfer it works better too. The issue i feel is that the coils being inboarded makes for a virtual pivot instead of a linear compression on the coils. I staged an experiment that proves the point, i placed a block of wood between the bumpstop on one side of the rear and a strap wrapped around the axle tube and chassis on the other droop side of the rear so that the rear end was virtually locked up. When i ramped it the front end worked perfectly. With both radius bolts in i got reasonable to excellent flex, and with a bolt removed i was able to hit bumpstops one side and dislocate a 2" coil by over 50mm before i ran out height on my small ramp. The entire time the body was virtually level.pinkfloyddsotm wrote:g'day milo, ive experienced the same problems as you , even with my front end xlinked,what ive come up with is the weight difference, theirs no weight over the rear so the back is just gonna flex like mad everytime , and also the radius arm setup front vs linked rear, if i was to do mine again id go linked front end, i might even go that way in the future, im going coilovers in the rear of mine soon so i can go stiffer spring rate and shock valving, only problem i can see with coils under the chassis rail is you'd need like 2" coils to sit the truck level , but you can imagine how much they'd drop out everytime. let me know what you think.

Outboarded coils would actually fit quite easily given that there is already 120mm of distance to the tyre from the chassis, but the Bull is right in that an extraordinarily long coil would be needed otherwise a funky retainer system would be needed.

Does anyone know if an 100 series chassis is wider again than a 80 series?

http://www.populationparty.org.au/

http://www.superiorengineering.com.au/p ... ts_id=4896

these things seem to help the front flex a bit more

these things seem to help the front flex a bit more

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

perhaps with normal patrol and cruiser chassis' but the issue here is definately not with the radius arm set up. I've had this thing ramped with a bolt out and the others loosened off so it's not a binding issue.mickyd555 wrote:http://www.superiorengineering.com.au/p ... ts_id=4896

these things seem to help the front flex a bit more

http://www.populationparty.org.au/

Banned

Re: options to widen rear of chassis rails

My feeling is that the weight is not an issue, in fact it's the other way around to what you have outlined. The forward weight bias would help to force the front to work and i've noted that when you ramp the car backwards so that there is a forwards weight transfer it works better too. The issue i feel is that the coils being inboarded makes for a virtual pivot instead of a linear compression on the coils. I staged an experiment that proves the point, i placed a block of wood between the bumpstop on one side of the rear and a strap wrapped around the axle tube and chassis on the other droop side of the rear so that the rear end was virtually locked up. When i ramped it the front end worked perfectly. With both radius bolts in i got reasonable to excellent flex, and with a bolt removed i was able to hit bumpstops one side and dislocate a 2" coil by over 50mm before i ran out height on my small ramp. The entire time the body was virtually level.

Theres a thing called "suspension frequency" and its to do with shock/spring geometry,spring rate & shock valving and how important it is to get the front to rear natural frequency balance equal which is harder than it sounds, due to weight differences. If you read that section on the coilover bible on pirate 4x4 you'll understand what i mean, although it refers to coilovers its still similar principle for us coil sprung vehicles. If i can tighten the rear end up and loosen the front, even if it means sway bar on the back.

also theirs only like 30mm difference in chassis widths between the 80 and 75.

as pinkfloyddsotm said, Valving and spring rates plays a huge part. Lucky for me the suspension in my 80 series is the result of about 5 years of competitive tuning on it's sister truck,

It rides and handles better than my BF falcon, goes round corners well too, with probably less body roll than standard even though it has no sway bars at all and 35's.

Just need to sort the brakes, add another 2 cylinders and I'll be cheering

It rides and handles better than my BF falcon, goes round corners well too, with probably less body roll than standard even though it has no sway bars at all and 35's.

Just need to sort the brakes, add another 2 cylinders and I'll be cheering

Re: options to widen rear of chassis rails

so is simply adding a limiting strap to the rear and maybe stiffer shocks the easy option..rockcrawler31 wrote: I staged an experiment that proves the point, i placed a block of wood between the bumpstop on one side of the rear and a strap wrapped around the axle tube and chassis on the other droop side of the rear so that the rear end was virtually locked up. When i ramped it the front end worked perfectly. With both radius bolts in i got reasonable to excellent flex, and with a bolt removed i was able to hit bumpstops one side and dislocate a 2" coil by over 50mm before i ran out height on my small ramp. The entire time the body was virtually level.

i think alot in your situation points to adding a sway bar!!!

michael

Hi there MILO, in your other threads we (the OL members) suggest you to use a rear sway bar but not too big to restrict your rear articulation but not limit your suspension travel. So was wondering have you tried it yet? And also we suggested you moving your rear coils outwards more but you said it would scrub/hit the tyres. Unless you move your rear coils outwards more you've really going to have a really unbalanced suspension set-up. Since you allready have a modified vehicle are you able to inboard your front coils to balance it up, but keep in mind it will be bad mannered then on road unless you have sway bars front and rear but have disconnect's for offroading. It's a same to change your rear end after the hard work you put into it, good luck.

NICK.

NICK.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Re: options to widen rear of chassis rails

I certainly have no issues with using a sway bar (some folks seem to be dead set against them), BUT it's one more thing under the back of the car to go wrong or break and it's a bandaid to the real issue. I have tried another experiment setting up a set of coils connected to the axle via a rod and clevis. Thanks to DRS and Lay80n who gave me the idea on the megatwon. It worked a little but the coils need to be stiffer and could probably still be too close to work. Would be a great idea on a standard width chassis i think. For the things i want this car to do it needs to be INHERANTLY stable and not held up by a secondary device.11_evl wrote:so is simply adding a limiting strap to the rear and maybe stiffer shocks the easy option..rockcrawler31 wrote: I staged an experiment that proves the point, i placed a block of wood between the bumpstop on one side of the rear and a strap wrapped around the axle tube and chassis on the other droop side of the rear so that the rear end was virtually locked up. When i ramped it the front end worked perfectly. With both radius bolts in i got reasonable to excellent flex, and with a bolt removed i was able to hit bumpstops one side and dislocate a 2" coil by over 50mm before i ran out height on my small ramp. The entire time the body was virtually level.

i think alot in your situation points to adding a sway bar!!!

http://www.populationparty.org.au/

Have you considered coilovers to widen the spring width?

Is the rear retained? I found with my ute the front didn't work at all and the rear just lifted and then dislocated if the the rear wasn't retained. Its front leaf and rear coil. When the rear was retained it then flexed everywhere.

The pic below, the rear would dislocate with the jack flat. Retained is as you see it.

Is the rear retained? I found with my ute the front didn't work at all and the rear just lifted and then dislocated if the the rear wasn't retained. Its front leaf and rear coil. When the rear was retained it then flexed everywhere.

The pic below, the rear would dislocate with the jack flat. Retained is as you see it.

Cheers

Slunnie

Discovery TD5, Landy IIa V8 ute.

Slunnie

Discovery TD5, Landy IIa V8 ute.

Banned

yer retaining the rear coils helps to, this is why im going coilovers too, they have more fine tuning abilities.Slunnie wrote:Have you considered coilovers to widen the spring width?

Is the rear retained? I found with my ute the front didn't work at all and the rear just lifted and then dislocated if the the rear wasn't retained. Its front leaf and rear coil. When the rear was retained it then flexed everywhere.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Currently fabricating a torsion bar sway bar system to induce some roll stiffness into the rear. It's not the ideal way to deal with the cause, but if it effectively deals with the symptoms, and cost's a whole lot less with a lot less dicking around then it becomes the most practical way.Black Bull wrote:Any updates on how you went with this Milo ?

Will be fitting it in the next couple of weeks after i get back from work, so i'll do a buildup thread on it or post here

http://www.populationparty.org.au/

You've probably already looked into it but, why not look at a custom set of progressive rate springs in the rear? You will retain the extended length so they don't fall off the seats at full droop and when under compression they will stiffen right up. Just may save a heap of fab work which still may not work as well as you want. I'd also look at a set of softer standard rate springs for the front.

PS. Love your truck mate, looks tuff as.

Rowen

PS. Love your truck mate, looks tuff as.

Rowen

Don't take life too seriously...it isn't permanent.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

thanks heaps mate, i thought i was finished working on it but it seems they're always a work in progress. I had dual rate coils on it but that was positively scary to drive because the first softer part of the coil let it flop around that much more. It seems the rate of the coils doesn't matter that much because it just wants to pivot around them.BadMav wrote:You've probably already looked into it but, why not look at a custom set of progressive rate springs in the rear? You will retain the extended length so they don't fall off the seats at full droop and when under compression they will stiffen right up. Just may save a heap of fab work which still may not work as well as you want. I'd also look at a set of softer standard rate springs for the front.

PS. Love your truck mate, looks tuff as.

Rowen

http://www.populationparty.org.au/

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

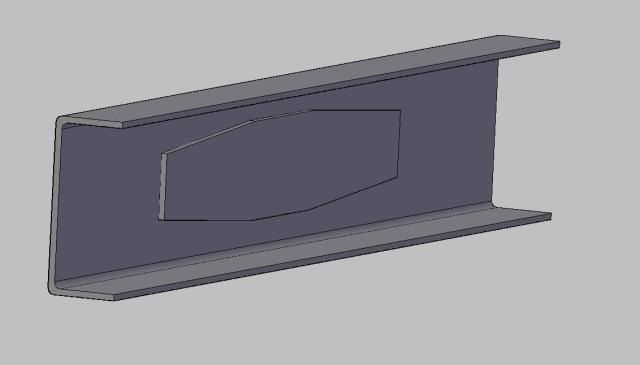

While we're on the subject. I'm hoping to mount the torsion bar through the chassis behind the axle, just in front of the rearmost crossmember. I have to use 50mm ID tube as the torsion bar is 46mm at it's thickest. Now depending on where on the chassis i weld in the tube as a boss, i may only have a little bit of height above and below the tube. While it's not critical for the rest of the truck that means that the rear crossmember (used for towing might only be relying on the horizontal (albeit dual thickness) portion of the rails. So i've drawn up a design to run the boss halfway through the bottom of the rail and have some strengthening ribs/gussets below that. If anyone here is half qualified or know what they're doing have a look and tell me what you think of the idea before i take it to an engineer to get laughed at.

I know my diagrams show plenty of space, it's just to show you the idea of what i'm thinking

side view

end view/cross-section

underneath

and 3D

I know my diagrams show plenty of space, it's just to show you the idea of what i'm thinking

side view

end view/cross-section

underneath

and 3D

http://www.populationparty.org.au/

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

cheers mate

here's the overall plan, with a LOT of thanks to Dale at 2DExtreme who has very nicely given me much advice considering he makes these and did himself out of a sale ( i was already in the process of making them though) To be honest if anyone wants to do this i'd just get dale to do them. I probably save a few hung in labour costs but for the time and effort it's worth getting it doné.

I've been re-learning CAD again today

here's the overall plan, with a LOT of thanks to Dale at 2DExtreme who has very nicely given me much advice considering he makes these and did himself out of a sale ( i was already in the process of making them though) To be honest if anyone wants to do this i'd just get dale to do them. I probably save a few hung in labour costs but for the time and effort it's worth getting it doné.

I've been re-learning CAD again today

http://www.populationparty.org.au/

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Look for a product called "Vesconite" a plastic alternative to bronze/brass bushing. It can be bought as bar stock or pre manufactured bushes in various sizes.

Alternatively they can machine it to suit.

AB Plastic in Hallam Victoria are combined with Vesco Plastics.

Or you could talk to AB about some "L7G" bar which is a woven cloth bushing material that is impregnated with graphite. It lubes and handles some extreme forces at the same time and can be machined in a lathe.

BTW, retaining the coils may be a simple solution and very easy to try as suggested above.

Cheers

Alternatively they can machine it to suit.

AB Plastic in Hallam Victoria are combined with Vesco Plastics.

Or you could talk to AB about some "L7G" bar which is a woven cloth bushing material that is impregnated with graphite. It lubes and handles some extreme forces at the same time and can be machined in a lathe.

BTW, retaining the coils may be a simple solution and very easy to try as suggested above.

Cheers

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

I can't figure out how to retain the coils thoughStruth wrote:Look for a product called "Vesconite" a plastic alternative to bronze/brass bushing. It can be bought as bar stock or pre manufactured bushes in various sizes.

Alternatively they can machine it to suit.

AB Plastic in Hallam Victoria are combined with Vesco Plastics.

Or you could talk to AB about some "L7G" bar which is a woven cloth bushing material that is impregnated with graphite. It lubes and handles some extreme forces at the same time and can be machined in a lathe.

BTW, retaining the coils may be a simple solution and very easy to try as suggested above.

Cheers

http://www.populationparty.org.au/

Banned

BTW, retaining the coils may be a simple solution and very easy to try as suggested above.

Cheers

Their should be a couple small holes in the tophat , i just used steel wire rope through a hole in the tophat ,around one the top coil wraparounds and back over the top of the coilhat between my crossmember held with couple bulldog grips, id show pics but i just cant take any clear enough pics underneath .the coil drops out a touch to take up the slack but it works.

Who is online

Users browsing this forum: No registered users and 4 guests