Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

WALKER EVANS INSIDE BEAD WONT BREAK.

Moderators: toaddog, TWISTY, V8Patrol, Moderators

WALKER EVANS INSIDE BEAD WONT BREAK.

OK Heres what I have.

15x8 walker evans mechanical beadlocked alloys.

37 x 12 Maxxis creepy krawlers.

A set of five. 1X new tyre, 2X worn but good tyres, 2x worn not so good tyres.

Have ran these at 6 to 10 psi every time ive taken them offroad, and used auotobalance in them. There no more than 2 years old.

I NEED TO SEPERATE THE TYRES FROM THE RIMS.

So my problem is this.

No one I have trierd so far has been able to break the inner bead. Now I know that they are not the easiest to do but every one that has tried has ended up saying "they have never had so much trouble before".

Many methods have been tried on conventional tyre removing equipment

by people with experience in the 4wd scene in Victoria.

Lindsays tyres, Razz tyres, Dynamic tyres all have had a real go at it with no success. As have another 4 regular tyre joints.

Dave @ Lindsays even tried soaking the inside of the inner bead with some brake fluid to help.

Cleaned the inner surface of the rim to help the tyre slide off the bead but nothing.

When pressure is applied, the tyre will completely fold back flat onto the bead the when pressure is released,

it just rolls back into place. One side wall has sustained some fresh damage as a result but thats all part of it I guess.

I am thinking its more of an equipment issue now rather than a method issue.

We have left the locking ring on to create some resistance, tried a slide hammer (nervously) but no luck.

I am stopping short of cutting the tyres off because I have sold them. Although I am happy to return the deposit, the

guy really wants the tyres.

So my question is this: Is there anyone that knows where I could take these wheels and tyres to get them taken apart?

Maybe a truck tyre joint? I have spoken to a couple and have been advised that, although there eqipment is (bigger) the small rim size (15") might not work on there machines. One guy said he wuld be nervous using a (jaws of life) style pnuematic "spreader" cause if the tyre dont give the rim might. Considering the value of them it would be too risky.

ANy suggestions, ideas, recomendations would be greatly appreciated. From me, the guy buying the tyres, and the guy buying the wheels both of whom are being very patient.

Thanks very much.

feel free to contact me if you think you can help

ph/sms 0425713164

or via PM on here.

Cheers Chris.

15x8 walker evans mechanical beadlocked alloys.

37 x 12 Maxxis creepy krawlers.

A set of five. 1X new tyre, 2X worn but good tyres, 2x worn not so good tyres.

Have ran these at 6 to 10 psi every time ive taken them offroad, and used auotobalance in them. There no more than 2 years old.

I NEED TO SEPERATE THE TYRES FROM THE RIMS.

So my problem is this.

No one I have trierd so far has been able to break the inner bead. Now I know that they are not the easiest to do but every one that has tried has ended up saying "they have never had so much trouble before".

Many methods have been tried on conventional tyre removing equipment

by people with experience in the 4wd scene in Victoria.

Lindsays tyres, Razz tyres, Dynamic tyres all have had a real go at it with no success. As have another 4 regular tyre joints.

Dave @ Lindsays even tried soaking the inside of the inner bead with some brake fluid to help.

Cleaned the inner surface of the rim to help the tyre slide off the bead but nothing.

When pressure is applied, the tyre will completely fold back flat onto the bead the when pressure is released,

it just rolls back into place. One side wall has sustained some fresh damage as a result but thats all part of it I guess.

I am thinking its more of an equipment issue now rather than a method issue.

We have left the locking ring on to create some resistance, tried a slide hammer (nervously) but no luck.

I am stopping short of cutting the tyres off because I have sold them. Although I am happy to return the deposit, the

guy really wants the tyres.

So my question is this: Is there anyone that knows where I could take these wheels and tyres to get them taken apart?

Maybe a truck tyre joint? I have spoken to a couple and have been advised that, although there eqipment is (bigger) the small rim size (15") might not work on there machines. One guy said he wuld be nervous using a (jaws of life) style pnuematic "spreader" cause if the tyre dont give the rim might. Considering the value of them it would be too risky.

ANy suggestions, ideas, recomendations would be greatly appreciated. From me, the guy buying the tyres, and the guy buying the wheels both of whom are being very patient.

Thanks very much.

feel free to contact me if you think you can help

ph/sms 0425713164

or via PM on here.

Cheers Chris.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Deflate tyre, lay down on ground and drive over it?

http://www.populationparty.org.au/

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Just sent him a text saying exactly that.

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Thanks fellas. I'm afraid we have tried it. The thing is ( I have been told) Walkers have a particularly wide inside bead. SO the tyre needs to come off gradually. Apparently you will never get the bead to unseat in one spot without the rest of the tyre having "slightly come off" .One of the tyre guys had a machine where the tyre lies down flat and spins as a bead breaker comes down onto it and slowly applies pressure. Obviously didnt work.

Was one of these.

I guess having a 37" tyre on a 15" rim allows alot of flex in the sidewall. Running over it with a car just folds the tyre almost flat.

Cheers

Was one of these.

I guess having a 37" tyre on a 15" rim allows alot of flex in the sidewall. Running over it with a car just folds the tyre almost flat.

Cheers

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

What about my suggestion of a car either side of the rim? Probably beating a dead horse but an easy enough thing to try.

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

if a tyre machine won't do it then driving a car on it has no chance.

try deflating it completely then going 4wd'ing. should be able to get the tyre to roll off pretty easy haha

try deflating it completely then going 4wd'ing. should be able to get the tyre to roll off pretty easy haha

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

if a tyre bloke can't do it they are crap

its easy no valve left use a proper bead remover and every time add a spacer /block it may taken 1/2 hour but i can garenty have delt with harder

its easy no valve left use a proper bead remover and every time add a spacer /block it may taken 1/2 hour but i can garenty have delt with harder

thanks jono

Skip 1995 tdi disco the new tourer

Tin Worn the scat crawler with charade (fwd) motor and auto patroll transfer and locked yota diffs all for under $1000

Skip 1995 tdi disco the new tourer

Tin Worn the scat crawler with charade (fwd) motor and auto patroll transfer and locked yota diffs all for under $1000

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Wow, there's lots of "experts" on here! I haven't paid a tyre shop to mount/dismount tyres for years and years - I dismount my tyres by driving on them, but I have seen something interesting. My 2c is that the autobalance powder has worked in between the tyre and inner bead, and is wedging the tyres on. We were out in the bush the other week and a guy had a fast bead leak. (Stopping every 5 minutes to air up) I suggested popping the tyre off and cleaning the bead properly.

What an epic PITA! - long story short - we ended up with a hydraulic jack off of the chassis of a 2500KG GQ on the bead (the car was jacked up) and 8 people bouncing on the tray before it broke. The tyres were mongrels - old carcasses - and the rims weren't rusty. The tightness, as far as I could tell, was due to the mud under the bead. I reckon the autobalance is doing something similar, epecially given the way that creepy's crown on 8" rims - maybe, just maybe, the inner bead is lifting and letting powder in, jamming the tyre on tighter once it releases.

BTW - I'm the guy that's waiting for the rims.

I don't have any great ideas and nearly posted this topic myself to see if anyone else has had dramas breaking the bead with autobalance in the tyres.

Steve.

PS I fully agree with the "working it around" strategy. I normally use wheelnuts - once the bead moves a tiny bit, drop a nut in, move around a bit and drop another nut in. Time comsuming, but it has worked for me.

I have had to cut two tyres off over the years. Both old, hard, 9/34 swampers.

PPS - It's cool TeeJay- I understand.

What an epic PITA! - long story short - we ended up with a hydraulic jack off of the chassis of a 2500KG GQ on the bead (the car was jacked up) and 8 people bouncing on the tray before it broke. The tyres were mongrels - old carcasses - and the rims weren't rusty. The tightness, as far as I could tell, was due to the mud under the bead. I reckon the autobalance is doing something similar, epecially given the way that creepy's crown on 8" rims - maybe, just maybe, the inner bead is lifting and letting powder in, jamming the tyre on tighter once it releases.

BTW - I'm the guy that's waiting for the rims.

I don't have any great ideas and nearly posted this topic myself to see if anyone else has had dramas breaking the bead with autobalance in the tyres.

Steve.

PS I fully agree with the "working it around" strategy. I normally use wheelnuts - once the bead moves a tiny bit, drop a nut in, move around a bit and drop another nut in. Time comsuming, but it has worked for me.

I have had to cut two tyres off over the years. Both old, hard, 9/34 swampers.

PPS - It's cool TeeJay- I understand.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Doesn't it hurt to drop a nut in?

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

What is a "proper" bead remover?hillbilliywheelchair wrote:if a tyre bloke can't do it they are crap

its easy no valve left use a proper bead remover and every time add a spacer /block it may taken 1/2 hour but i can garenty have delt with harder

We have tried throwing in some balance weights to prevent the tyre from rolling back into the bead but even this has failed.

Will give the 2 cars driving over the tyre a go on Tuesday night see how that goes. Otherwise still looking for someone in Vic prepard to give it a go.

Thanks for the replies.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Driving a car onto it dosent work all the time. Last tyres I took of rims, we had a heavy 75series sitting onit. Then had to use tyre levers and a beadbreak to get it off. In my case though I am sure a tyres shop would have had it off in seconds.

THOUGHT FOR THE DAY....

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

had the same drama with mine, as have many people with walker evans rims, pro comp have a tyre removing machine that will do the job, good luck!!!!!!!

80 series with chrome wheelnuts !!

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

you can make one or just take it to the local tyre shop

and after a bit of research some evens rims have a safety bead on the rear lip making it difficult

you can make a simple one like a u shape on a pole that you caqn drive on consecrating the weight around the bead

or a clamp and threaded mechanism like some of the truck tyres use

and after a bit of research some evens rims have a safety bead on the rear lip making it difficult

you can make a simple one like a u shape on a pole that you caqn drive on consecrating the weight around the bead

or a clamp and threaded mechanism like some of the truck tyres use

thanks jono

Skip 1995 tdi disco the new tourer

Tin Worn the scat crawler with charade (fwd) motor and auto patroll transfer and locked yota diffs all for under $1000

Skip 1995 tdi disco the new tourer

Tin Worn the scat crawler with charade (fwd) motor and auto patroll transfer and locked yota diffs all for under $1000

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

I had a similar issue with a set of BG Muddies on GU rims .. I used the same autobalance power in it as it would not balance any other way ..

The tyre ended up being cut off the rim (as it was well worn and being replaced)

the other thing I have seen done is a big heavy slide hammer made specifically for the job of removing stuck beads .. basicallt was half a crowbar with a slanted foot and nylon cover and a great big heavy walled pipe hammer on top. I had seen it remove sikaflexed on swampers from rusted rims that had been on there a looooong time .. I was not paying a great deal of attention to the state of the rims afterward though .. the tyres were not damaged

The tyre ended up being cut off the rim (as it was well worn and being replaced)

the other thing I have seen done is a big heavy slide hammer made specifically for the job of removing stuck beads .. basicallt was half a crowbar with a slanted foot and nylon cover and a great big heavy walled pipe hammer on top. I had seen it remove sikaflexed on swampers from rusted rims that had been on there a looooong time .. I was not paying a great deal of attention to the state of the rims afterward though .. the tyres were not damaged

" If governments are involved in the covering up the knowledge of aliens, Then they are doing a much better job of it than they do of everything else "

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

i good truck tyre shop should be able to get it off no worries, look for one that does agricultural/ mining... if youve seen them change a tyre on a haul truck, sometimes the rear bead seat doesnt like coming off... they have the training and the tools to get it off.

turbos are nice but i'd rather be blown

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

And there's the problem. In this case, the Tyres are almost junk and the rims are far from it.love_mud wrote:I was not paying a great deal of attention to the state of the rims afterward though ...

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

toughnut wrote:Doesn't it hurt to drop a nut in?

Farkin pissed myself laughing at this one had the same thought when reading Steve's post ............ nice !!!

Seems a common thing with the Walkers, don't know if Ryano can shed some light but I think the auto balance beads sounds like the culprit or at least part of the problem.

brooksy

C44F-Custom 4x4 Fabrications

0400 443 802

brooksy72@live.com.au

0400 443 802

brooksy72@live.com.au

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

What an epic task this was.

Finally success. And it came in an unexpected way.

Had an electritian come over the house to do some work.

He saw the tyres in the garage and commented on them to the Mrs.

She mentioned I was having trouble seperating them and he said "tell your hubby to call me"

So I did and he put me onto Total Tyres in Oakleigh. Shaun tried on the normal machines

and quickly realised he wasnt going to win. Took it over to the truck tyre section on a massive , big ass, gigantic, really really big bead breaker used on semi tyres. Around around the tyre went about 20 odd times and the bead finally came off. UNFKNbelievable. Will be taking the rest back for him to do now.

Thanks to everyone for there advise and ideas. And to Shaun, Total Tyres Oakliegh.

Cheers

Chris.

PS will post up some pics of the rims so you can see how the autobalance was really to blame for this situation. I would use autoblance again but not on a Walker Evans rim.

Finally success. And it came in an unexpected way.

Had an electritian come over the house to do some work.

He saw the tyres in the garage and commented on them to the Mrs.

She mentioned I was having trouble seperating them and he said "tell your hubby to call me"

So I did and he put me onto Total Tyres in Oakleigh. Shaun tried on the normal machines

and quickly realised he wasnt going to win. Took it over to the truck tyre section on a massive , big ass, gigantic, really really big bead breaker used on semi tyres. Around around the tyre went about 20 odd times and the bead finally came off. UNFKNbelievable. Will be taking the rest back for him to do now.

Thanks to everyone for there advise and ideas. And to Shaun, Total Tyres Oakliegh.

Cheers

Chris.

PS will post up some pics of the rims so you can see how the autobalance was really to blame for this situation. I would use autoblance again but not on a Walker Evans rim.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

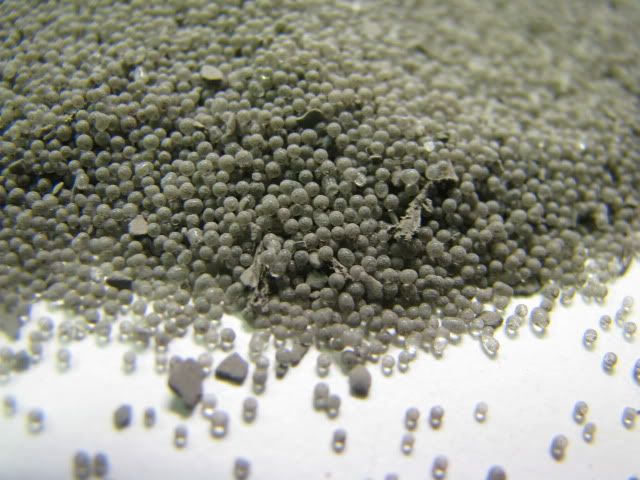

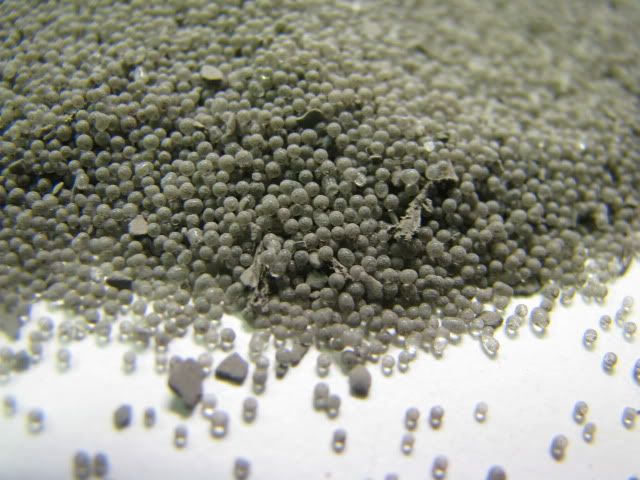

Here are the pics I promised.

This is what the balancing compound did to the inside of the tyre. Looking at how much was left it has decreased considerably from the initial amount we put in.

This is where the problem occured. The "dust" worked its way in between the rim and tyre.

This rim was cleaned with all sorts of solutions to remove the "dust". Here you can see how thick a layer it actually was.

And theres that safety lip that was mentioned.

Microcosmos of pain.

Again thanks to all.

This is what the balancing compound did to the inside of the tyre. Looking at how much was left it has decreased considerably from the initial amount we put in.

This is where the problem occured. The "dust" worked its way in between the rim and tyre.

This rim was cleaned with all sorts of solutions to remove the "dust". Here you can see how thick a layer it actually was.

And theres that safety lip that was mentioned.

Microcosmos of pain.

Again thanks to all.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Gwagensteve wrote:

Steve.

Got your auto-balance beads ready Steve?

RN wrote:pussy is out, its the log for me... Thank you Jesus.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

I haven't bothered balancing a tyre that goes offroad for over ten years.

Steve.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

I'll be reusing the autobalance beads left over in my new tyres and wheels.

37 Procomp xt Muddies on 17 inch Walkers.

Yeah ShortyIQ right.......

Youve got some cleaning to do Steve.

37 Procomp xt Muddies on 17 inch Walkers.

Yeah ShortyIQ right.......

Youve got some cleaning to do Steve.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Sweet, now Steve can drop a nut in.

hands and mums dont count!!!

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

x2Gwagensteve wrote:I haven't bothered balancing a tyre that goes offroad for over ten years.

Steve.

They seem to drive just fine without balancing. I guess with that much rubber and suspension lift, the vibrations just get filtered out anyway

2001 GU Patrol DX wagon, TD42, Air Lockers, twin spare carrier, Barrett HF, 35" Treps, high pinion rear, Staun beadlocks, 60l Engel and more!

Banned

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

What do you think caused the balancing beads to break down?

Natural 'wear n tear'?

or do you think it was caused by water or moisture inside the tire?

Luke.

Natural 'wear n tear'?

or do you think it was caused by water or moisture inside the tire?

Luke.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Cant answer that Dork. This is the very first time I have seen Autobalance after its been used so i dont know how it wears.

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

autobalance = cheap beadlock

After reading this thread I might start running autobalance just for its beadlocking ability.

After reading this thread I might start running autobalance just for its beadlocking ability.

Nitto Mud Grapplers, Lockrite, 4.3s, Trail Ready BL, PTO, High pinion rear,Gu diff with Buds Customs armour and heaps of Superior gear, 24% Reduction .

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

In a bit of a book end to this story, I picked the wheels up from TeeJay and I've cleaned them up.

The leftover autobalance powder left a caked deposit on the rim which had to be scraped off. Interestingly, if it was hit with solvent it behaved like tar and had to be dissolved away, which makes me wonder if slightly oily compressed air when refilling the tyres might have helped accelerate breakdown of the beads.

Also, the rims look to have had a smear of bead sealer on the inner bead.

Anyway, they have come up a treat with some polish and aluminium cleaner

Steve.

The leftover autobalance powder left a caked deposit on the rim which had to be scraped off. Interestingly, if it was hit with solvent it behaved like tar and had to be dissolved away, which makes me wonder if slightly oily compressed air when refilling the tyres might have helped accelerate breakdown of the beads.

Also, the rims look to have had a smear of bead sealer on the inner bead.

Anyway, they have come up a treat with some polish and aluminium cleaner

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Re: WALKER EVANS INSIDE BEAD WONT BREAK.

Bead sealer hey? MMMM interesting. I didnt think any was used when they were assembled. Is it possible that the brake fluid used to lube the bead up caused this?

Anyway I really want to know how you got the rims so damme shiny. Look brand new. Whats the product. where from and how much. Supacheap got it?

They look ace.

Cheers

Chris

Anyway I really want to know how you got the rims so damme shiny. Look brand new. Whats the product. where from and how much. Supacheap got it?

They look ace.

Cheers

Chris

Who is online

Users browsing this forum: No registered users and 1 guest