The mach 1 was crap and stuffed my springs.

The mach 2 was OK but ripped itself to bits and took out the axle tube

so I am onto the mach 3.

I will post some pics as I go and you can hang shyte on my welds

Peter.

OK, so lets be logical. So you've got all of the parts there to do a coil conversion (no more stuffed leaf springs) but you're going to buy new leaves, build a trac bar. Then 6 months later decide to do a coil conversiondroopypete wrote:(fingers in ears) LA LA LA I'M NOT LISTNING I'M NOT LISTNING LA LA LAsierrajim wrote:Stop being so soft and put the coils in

You know you're going to do it anyway

Did you run a shackle on the chassis end to allow for the ecentric arc of travel in the rear end?? I modeled a GQ radius rod running to a shackle at the chassis end in ProENGINEER, was thinking bout going that way. Have seen it work before and would be cheap and easy to do. Just make a mount over the top of the zook centre, and re-inforce it, then a crossmemeber under the chassis. Though im still not sure, coils would be much better depends on $$$ at the time. The anit-squat you get with a trac bar is a downside too.droopypete wrote:The mach 1 was a single bar from the top of the centre to the chassis rubber on both ends, all it did was make the pinion drop, bending springs and stressing out uni's.

the second one was a triangulated bar rubber mounted at the center of the diff and rubber mounted to a hanger at the chassis,

this worked to a point but as James was quick to point out, this design assumes that the suspension cycles in an arc radiating from the chassis end of the track bar, whereas it travels in an almost vertical plane, so the track bar must be infuencing the suspension in an adverse way (contery to popular beleif) and as the forces involved are huge, it just ripped itself off the axle tube.

Peter.

I think that part of the success of track bars on Hiluxes is that they can be much longer. This limits the angle changes that they force the springs into.Damo wrote:Perhaps you can quiz some of the Hilux guys, a few of them run track bars with good results (from what I have heard/read).

I do agree with Jim though, coils are the logical solution. Which is probably why you are persisting with leaves (logical being the operative word)

when you have a light leaf pack, you get a soft spring rate which can result in a lot of flex (or sag). probably the complete opposite to brand new 2" lifted king springs. anyway...zookmad wrote:Sorry to be a noob but i don't know squat about track bars. Can you use something like a rotatable joint (eg. in your steering arms) to allow the track bar to move at the chassis so the diff articulates with no limitations

a track bar mounts to the chassis and usually 2 places on the diff housing, usually one above the housing tube and the other in front or under. the 2 mounts on the diff housing stops this twisting, or reduces it a lot.baddboy posted but didn't wrote:

Thanks for the great reply. I have spoa with soft springs and have to replace rear springs many times. But i can't quite grasp what you ment with this sliding tube. Is this the single link or the 2 link setup. By the way i understand what was said this wouldn't work as the diff can still rotate backwards and forwards with this system as what you said the tailshaft slides in and out while aticulating so the track bar will also slide in and out. Wouldn't that allow the diff to rotate up and down still causing spring warp?SiKiD_01 wrote:

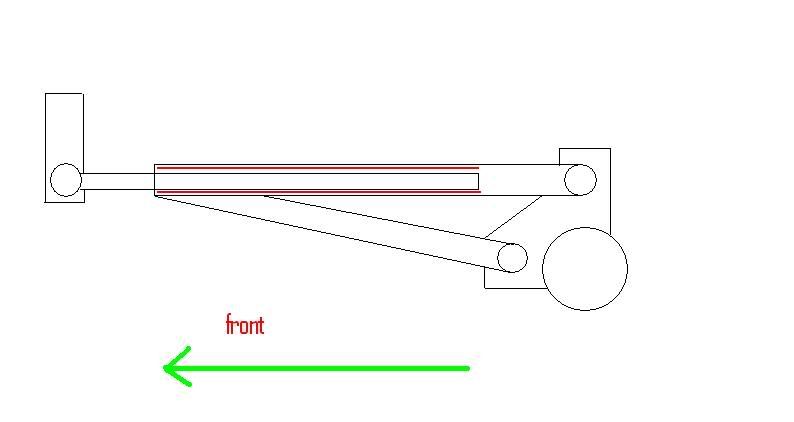

there have also been track bars where a round bar is slid into some tube. this means you can have a fixed mount on the chassis, as well as the fixed diff mounts. the bar can slide in and out of the tube, and it is also able to spin as it wants inside.

because the leaf springs are fixed at the front mounts, the diff cannot move forwards or backwards much. the round bar is slid into the tube, and runs almost the whole length inside the tube, leaving only about 3"-4" outside the tube, this lets it slide in and out. this also depends on how much flex you have.zookmad wrote:Thanks for the great reply. I have spoa with soft springs and have to replace rear springs many times. But i can't quite grasp what you ment with this sliding tube. Is this the single link or the 2 link setup. By the way i understand what was said this wouldn't work as the diff can still rotate backwards and forwards with this system as what you said the tailshaft slides in and out while aticulating so the track bar will also slide in and out. Wouldn't that allow the diff to rotate up and down still causing spring warp?SiKiD_01 wrote:

there have also been track bars where a round bar is slid into some tube. this means you can have a fixed mount on the chassis, as well as the fixed diff mounts. the bar can slide in and out of the tube, and it is also able to spin as it wants inside.

This is what Pete and i spoke about. If you really look at it closely it will bind and hinder suspension travel. It will nodoubt work in saving your springs but it will bind on a zook.SiKiD_01 wrote:because the leaf springs are fixed at the front mounts, the diff cannot move forwards or backwards much. the round bar is slid into the tube, and runs almost the whole length inside the tube, leaving only about 3"-4" outside the tube, this lets it slide in and out. this also depends on how much flex you have.zookmad wrote:Thanks for the great reply. I have spoa with soft springs and have to replace rear springs many times. But i can't quite grasp what you ment with this sliding tube. Is this the single link or the 2 link setup. By the way i understand what was said this wouldn't work as the diff can still rotate backwards and forwards with this system as what you said the tailshaft slides in and out while aticulating so the track bar will also slide in and out. Wouldn't that allow the diff to rotate up and down still causing spring warp?SiKiD_01 wrote:

there have also been track bars where a round bar is slid into some tube. this means you can have a fixed mount on the chassis, as well as the fixed diff mounts. the bar can slide in and out of the tube, and it is also able to spin as it wants inside.

the 'slap' area is in red. this method will not work if there is only a single mount on the diff. if it were a single mount, it would just slide in and out like the driveshaft would.

Wise words Graham, but you are the king of being chronologically challengedgrimbo wrote:see it can happen very easily, you think "that wasn't too bad only a couple of months" and then you realise it was a couple of yearsdroopypete wrote:Jesus H Christ!!!! I just worked out how long my car has been off the road

I need a good boot up the arse

Peter.

Users browsing this forum: No registered users and 1 guest