Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Borg Warner T98 gearbox to Series transfer questions

Moderator: Micka

Thanks Nick,

Still not 100% on the bellhousing - I'm taking the whole thing up to the rod shop next week, he'll have something that can be adapted for sure.

AFAIK - a holden six to T5 / toploader ?? should be easy. The biggest problem will be the drivers side clutch slave. I might look at a tremec? ram type cylinder (no throw out fork type).

The adapter plate is exactly 1" thick - the overall bell/box/case length should be the same or slightly shorter than a standard series setup, so at least I don't have to muck around with prop shafts and crossmembers.

Still not 100% on the bellhousing - I'm taking the whole thing up to the rod shop next week, he'll have something that can be adapted for sure.

AFAIK - a holden six to T5 / toploader ?? should be easy. The biggest problem will be the drivers side clutch slave. I might look at a tremec? ram type cylinder (no throw out fork type).

The adapter plate is exactly 1" thick - the overall bell/box/case length should be the same or slightly shorter than a standard series setup, so at least I don't have to muck around with prop shafts and crossmembers.

Did the trip to Castlemain and picked up a bell housing. The 435 has exactly the same mounting as a toploader  CRS do a holden six bell, It's only a 3/4 type not full circle and the slave is exposed, gonna be a bitch to water proof.

CRS do a holden six bell, It's only a 3/4 type not full circle and the slave is exposed, gonna be a bitch to water proof.

The amount of engines you can get kits for fitting in front of the np435 is . All the good motors are catered for.

. All the good motors are catered for.

chevs, 308, 253, hemi, toy v8, nissan, ford six, late ford six, com V6...............

The amount of engines you can get kits for fitting in front of the np435 is

chevs, 308, 253, hemi, toy v8, nissan, ford six, late ford six, com V6...............

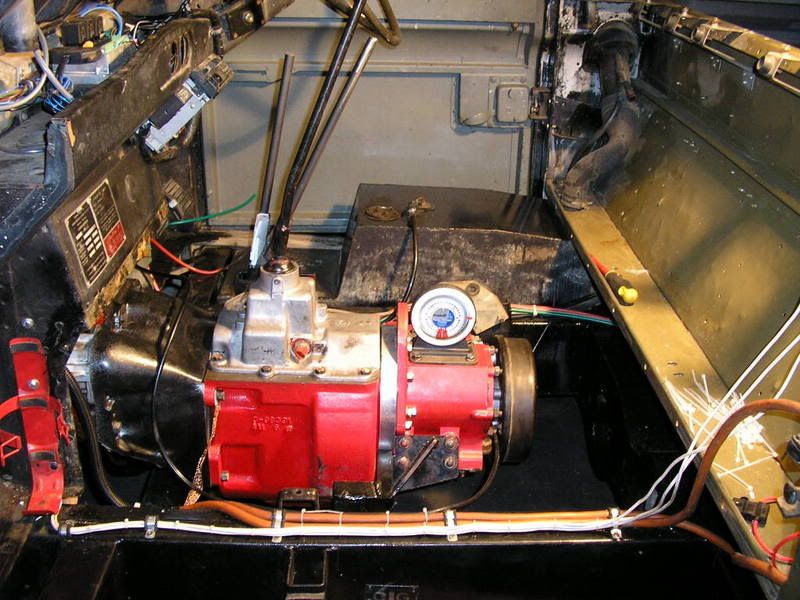

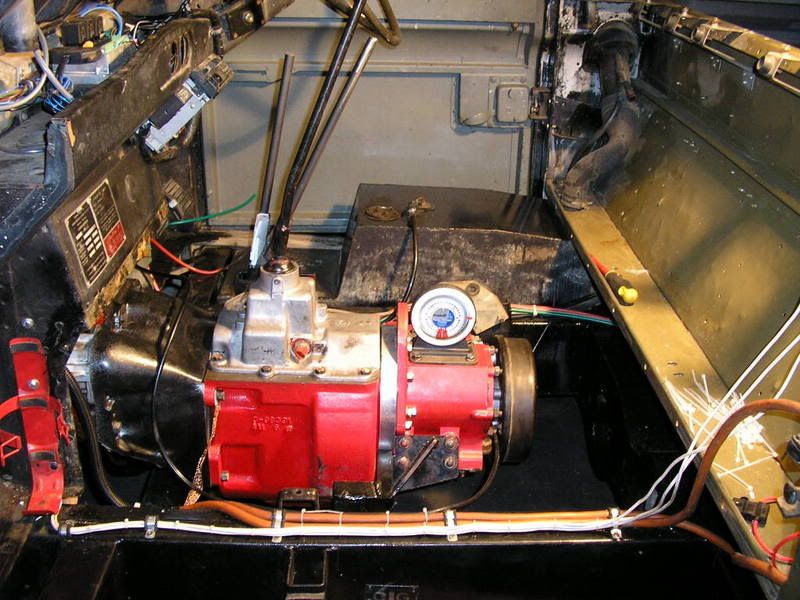

Finally got the thing in, had a few dramas getting it square. The old drivetrain was skewed around 5 degrees as well as having a down slope of 7 dg. All fixed now, extended the mounts and set it square to the chassis. (hope the chassis is actually square to the diff)

Now have a 1.5 degree drivetrain slope - I don't think I need caster wedges to compensate for this, no wonder it was rough as guts @ hwy speed before.

before - not much clearance, shaft rubbed all the time even though I still had the axle straps fitted :

after - heaps better, but I now need new front and rear shafts. They don't even make it to the flanges. : (

Now have a 1.5 degree drivetrain slope - I don't think I need caster wedges to compensate for this, no wonder it was rough as guts @ hwy speed before.

before - not much clearance, shaft rubbed all the time even though I still had the axle straps fitted :

after - heaps better, but I now need new front and rear shafts. They don't even make it to the flanges. : (

Yeah - didn't touch the X-member, the whole setup is the same length as the series box / bell (to the millimetre). However the ford box is much deeper and will foul the x-member. I could've cut out 3/4 inch off the top of the cross, but it fixed other drivetrain problems to raise the box.Woop wrote:I'm impressed Simon--looks really good. Is that the Bellhousing from the Rod shop? Were you able to fit it all in without moving the gearbox xmember?

NIck

The passenger side transfer case mount also needs cutting to clear the fat arse ford box and a bit of cutting of the seat box is in order (next job).

The bell is a rod shop stock item, the slave is a 3/4" bore hilux unit on a rod shop bracket. Dellow should also make suitable bells and they may even be full circle types ??? If you need a bell it will pay to take the box to Castlemain so they can see it - as they know jack about 4x4's and will tell you they have nothing to suit.

I'm a bit pissed about the clutch, as the land rover pressure plate is too big to fit inside the new bell. I'm stuck using a holden 1 tonner pressure plate and stock cast flywheel. I'm a bit dissapointed about this as I have a very heavy steel flywheel to suit the 9 1/2" landy clutch setup, but this is now no good to me, although with the granny low the holden clutch should be up to the job.

Question time - (Ben ? / anyone?)

I'll be doing your suspension mods (some day).

http://www.outerlimits4x4.com/phpBB2/vi ... leaf+taper

Did the standard prop shafts work - or did you have to fit longer slip travel shafts? I'm tossing up on wether to just get my shafts lengthend or get custom long slip units. $$ are tight - so if the standard lengths are good I'm happy.

Also any thoughts on refitting the chassis to gearbox rod ? Does it actually serve a usefull purpose?

Thanks

Simon

Simon, I used my standard (military) props and have never had a problem. If yours are only a tiny bit too short now, can you fit spacers at the diff and use longer flange bolts???

I kept the gearbox rod but replaced the rubber bushes with poly (shockie) bushes. I think it limits the motion of the drivetrain somewhat.

I kept the gearbox rod but replaced the rubber bushes with poly (shockie) bushes. I think it limits the motion of the drivetrain somewhat.

_____________________________________________________________

RUFF wrote:Beally STFU Your becoming a real PITA.

Finally on the road. Gota say I'm stoked - never thought it would be this good. The gearing seems to really suit the holden six. I was a bit concerned with the gear ratios - having essentially only a three speed, but Its actually better than the rover four speed. Unless comming to a near complete stop, i'm only using 3rd and 4th.

By sorting out the drive train geometry, I've picked up an easy 30% in power. The 186 now revs sweetly to 5500 + rpm - I'm guessing the trans was way out of alignment before, as a rough as guts 4000 was the best it could manange.

Oh yeah - fitted the chassis rod, it really is needed - just pulling on the hand brake would push the drivetrain forward around an inch.

By sorting out the drive train geometry, I've picked up an easy 30% in power. The 186 now revs sweetly to 5500 + rpm - I'm guessing the trans was way out of alignment before, as a rough as guts 4000 was the best it could manange.

Oh yeah - fitted the chassis rod, it really is needed - just pulling on the hand brake would push the drivetrain forward around an inch.

Who is online

Users browsing this forum: No registered users and 2 guests