If you're running driveline cv parts made up for say, 80kw fwd cars with triple the capacity and about4 times the weight, but running a 30kw trailbike engine I dont think the risk of breakages is that high.

It's not like we're running heavy tyres with trailbike and ATV wheels is it.

If I look at building one of these later (cant do it now but after I've got the house then I'd be interested) then I'd be using front and rear half shafts out of some very common small car (eg KE laser would be good).

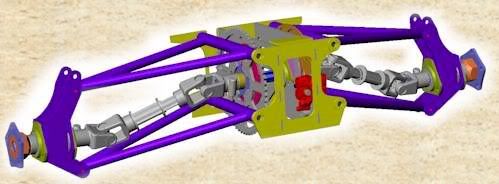

The axle would be thick tube at either end (might even go solid if weights not a problem) to a welded on plate at one end (the other end would need to be able to pass through the axle bearing to replace the sprocket) that the car CV would bolt to. None of these slide in/circlip type arrangements.

Kind of like a hybrid between an IFS Hilux/Vitara diff/axle with a go kart.

Drive would be by chain to a side offset sprocket for better centre clearance.

I might bolt those plates on at both ends first during the testing stages, since I may end up changing the source CV's used if I start breaking them.

Busted CV = $50 at the wreckers max, and probably no more than about 6 minutes to repair (replace whole shaft). After all it's only gonna be about 8 bolts to undo and do...... 5 minutes will be finding where you dropped that nut in the dirt

Similar to go kart on the disc fitment too. Seperate circuits with a kind of two in one pedal for individual control. With the kind of park brake you see on golf buggies on each too for some dragging turn capability.

A car steering box and rods would probably be used for strength reasons, but I'd be sticking with a vitara style design for the front wishbones, although this would be tube made rather than using massive car castings..

It's an easier steering design too, and could easily be run at both ends....although except for showing off I cant see why you need 4ws on an 8 foot long buggy..

The rear I'd probably look at a swingarm type arrangement, and then CV's as well to allow greater suspension movement at the back end than just CV's would allow. This would also allow for a much ligher rear frame (which is exactly how and why it's done on motorcycles).

So vertical motion controlled by the swing arm, and left to right flex by the CV's.

May end up not working (two different methods of flex might make the balance hard to get) but I'd want to give it a go. If it didnt work, you could always lock the swingarm in place - maybe have it adjustable height for between stages with locating pins, but fixed during the stage.

If the balance in the spring rates for the main swingarm and the individual wheel springs works, I might consider it for the front too.

Pity there's no adjustable height mid stage, cos the swingarms and airbag combo would rock.

The chain routing mihgt be interesting - the way I see the best simple power coupling arrangement would be using 6 sprockets (erk) I might consider running 8 for better chain routing.

Hmmm 8 sprockets....... anyone thinking of the possible gearing options?

Im also tossing up the idea of some form of belt drive from my reverse/transfer box instead of chain though. Guaranteeing tensioning the drive belt might be too hard in the potentially wet or dusty conditions though, and belt drives are renowned for being fragile, so they would need to be protected very well (probably run fully enclosed would be the only way).

Reduction gear ratios would then be more dependant on the transfer case sprockets, as opposed to the kind of portal style double reduction.

Not so many choices with gearing when dealing with pulleys as there is with sprockets.