Nutter Engineering Turbo Conversions (Dial Up Will Die)

Posted: Tue Apr 17, 2007 11:10 pm

Disclaimer:

its 2 AM and I'm using a borrowed keyboard because i though mine might like some beam and coke earlier in the week, if things don't make sense its cause I haven't slept for a while. Let me know and I will edit things.

Car Specs

1992 GQ LWB Wagon

2.2 ton unloaded

RB30 Carby motor

9.2 to 1 static compression

Running Bunsen burner/BBQ ring gas system.

4.3 Diff ratios

5 speed manual

100kw at Flywheel

2 inch body lift

2 inch spring lift

52kw at Rear Wheels

0-100 in 15.6 seconds

1/4 Mile in 20.6 seconds

Top speed on 31 inch tyres 132kph after approx 2km of flat out in 4th

All stock, no exhaust mods no internal mods.

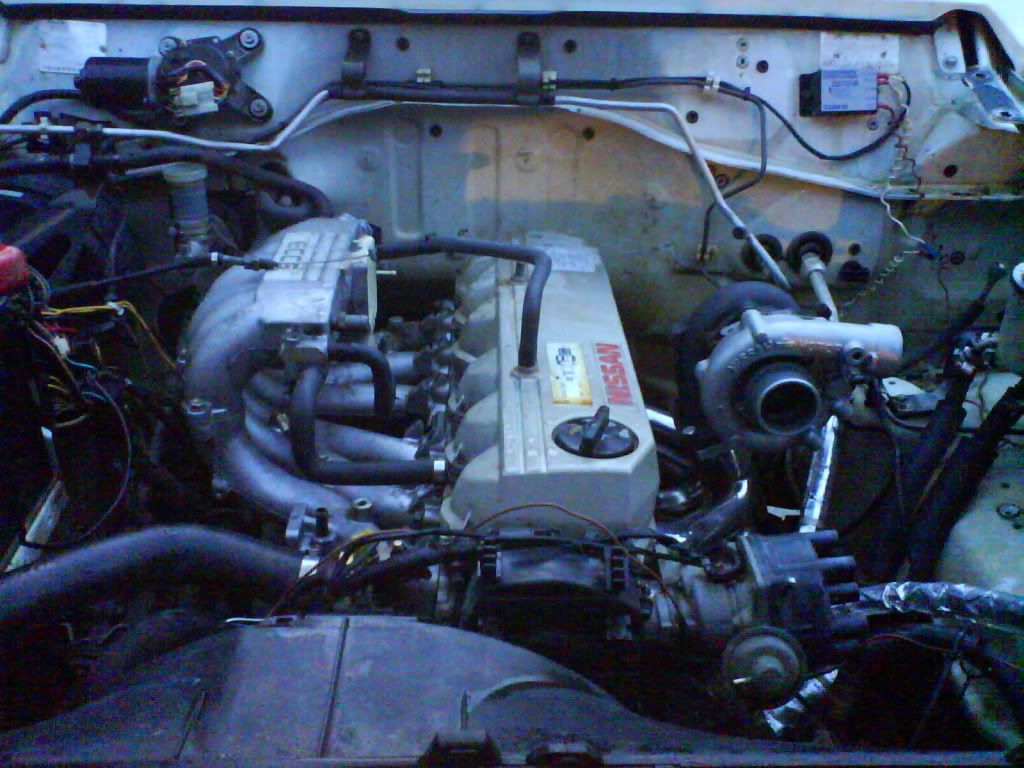

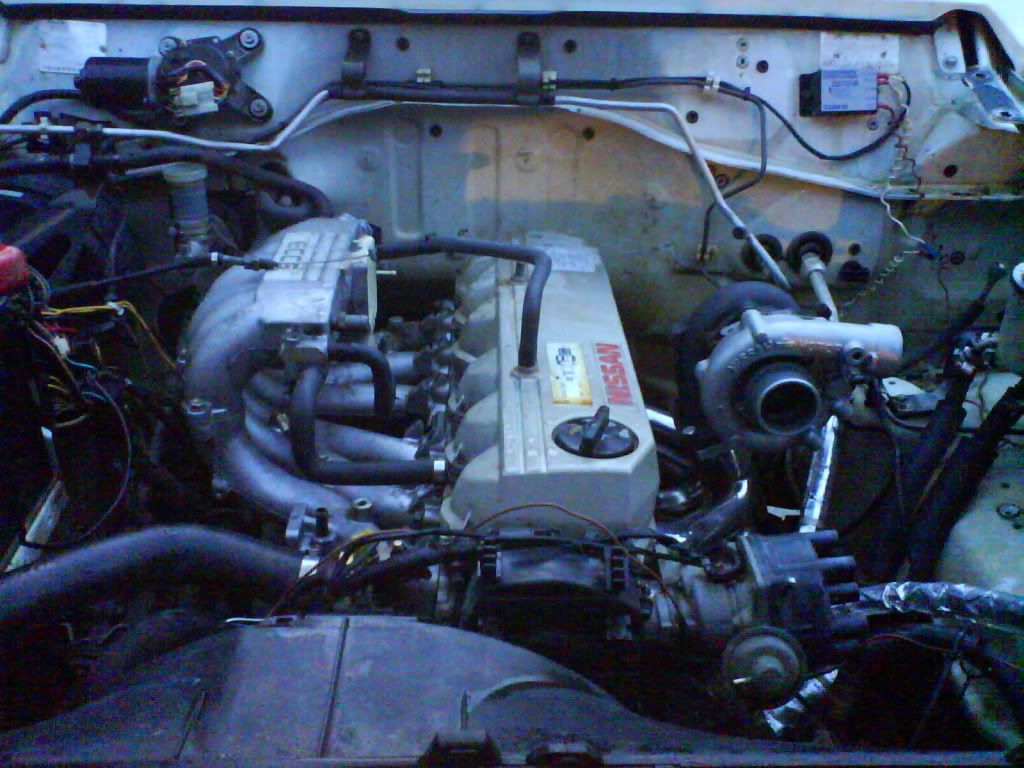

OK so I started with this:

Now what we do is remove everything, intake manifold, exhaust manifold, charcoal canister all fuel and pollution equipment, and there is a lot of this shit as it was hard to make the GQ comply with ADR's with a carby. Of course for those of you who dont know they ran carby instead of injection like the VL and R31 Skyline as they somehow apparently got a better torque spread with carby.

Next step was to Source a VL or Skyline intake manifold, for those of you contemplating this don't waste your money on a genuine turbo manifold there not as good. A lot of guys fit the longer runner N/A manifold to there VL's and make more power over wider rev band. You can source the N/A intake for $20 or less.

You then buy six 18mm welsh plugs and JB weld them (JB weld is a super strong resin) into the injector holes (disregard this if you are running it on petrol and keeping the injection you will need these bosses).

I also stripped of the EGR valves, warmer pipes, fuel rail and reg and anything else EFI or pollution related, most holes where covered with 1.5mm tin and bolted using original holes.

Next bit is to fit it up, using new gaskets and your laughing should start looking like this:

Next step fitting the new exhaust manifold, I choose to go High mount for a few reasons.

1. No engine mount or body mods.

2. I can remove turbo in about 15 minutes everything is easy to get to.

3. its out of the water and mud, yes it still gets some but not submerged so no cracked housings.

4. Huge runners, fast spool times, plenty of room for head and cam mods later.

Pics below.

Don't bet getting excited by how pretty it looks after 5 minutes they go all different colors, and you can hardly see them.

The Turbo

I have chosen to use a Garrett T3 as originally used on VL's. I have had it completely rebuilt including new core, wheels shaft and all seals bearings etc. So its brand new inside. It is running a newer style front wheel which produced lower air temps on the compressor side and flows better at higher revs. Basically like High Flowing but without going over the top.

It still runs standard rear wheel so it spools early and hard, also has fantastic throttle response, no lag great combo. These are a direct bolt up for the manifold as they use the T3 flange.

The waste gate can be done one of two ways, the easy way and the cheap way.

Easy way is to get a blank flange and bolt it to the back of the turbo and run your exhaust from that. On the high mount manifolds they have a 7th runner for an external gate, you bolt it on and youre done.

The cheap way (fine for 15PSI or less) is to take the VL dump pipe and cut it off so only the gate is left, you then weld a 3 inch flange to this so you can bolt your exhaust onto it. You cant use the VL dump pipe stock as once you high mount your turbo its upside down, so a stock dump pipe would go through your bonnet and over the car.

Because the turbo is upside down you also need to fit the waste gate to the opposite side. I made a bracket from angle iron and just kept grinding till it was nice

Pic below shows the lines and modified wastegate, the gate is not the prettiest thing in the world but makes the same power as a $200-$300 custom one.

In the below photo you can see the 3 braided lines that feed oil pressure and water in and out of the turbo. There is a 4th steel tube mounted on the bottom that gravity feeds hot oil back to the sump.

The lines are pretty expensive part of the conversion, looking at $400 just for 3 lines and the drain

As far as I know patrols all use the late style RB30 blocks that have oil and water feeds and returns already there. Series 1 VL commodores don't have these feeds so check b4 you buy your next block.

Next step is to mount the intercooler, for this I have chosen a 600X300X75mm unit, it is a dual pass, bar and plate unit so what happens is the air enters hot through the bottom hose, goes across the cooler then up at the end tank and back through for a second pass. Its like having 2 coolers one on top of the other. These are a little more than traditional coolers but at $250 no a huge investment.

These are very effective coolers providing you don't get one thats too small for your application. Mine pulls so much heat out the top half of the cooler never even gets warm.

To bolt it up its simply 4 bits of flat steel or in my case aluminum bent 90 degrees and bolt through the radiator support panel and lower support rail.

You now need to cut two 100mm holes in the support panel to allow for the cooler pipes to pass through these are easy to mark once the cooler is in place. I then cut come old fuel hose long ways and stuck it around the holes before placing the silicone joiners in.

The joiners are worth a fortune I found a great place on the net selling good ones for great prices, much better than I could get even at trade.

By now you should be looking like this:

Next is the fun part.....I wanted it to look stock..So instead of gutting the grill I got the grinder out and spent 2 hours grinding the back of the grill till there was nothing left. The end result is being able to fit the grille with all horizontal bars intact and looking like factory.

If you want the world to know your packing boost disregard above step and chop ya grill up fully hektic styles

End result should be like this:

Are we there yet????

Not quite but not long to go......

Next step is the cooler pipes, from the turbo outlet to the cooler I used 2.5 inch as the turbo is only about 45mm exit diameter, from the cold side of the cooler to the throttle body I ran 3 inch as thats the carby size and cooler outlet size.

POD Filter was only temporary and has now been replaced with an Airbox as pictured.

Should now be looking like this :

At this point youre nearly done....

Next point is to either buy 3 inch mandrels and make a new exhaust or go and get one custom made. Mine is 3 inch from the dump pipe back running 1 straight through muffler, at cruise speeds you wouldn't even know it has an exhaust under acceleration you can just tell, for me its perfect as I an a V8 boy I hate the sound of a 4 or 6 with sports system so the less I hear it the happier I am.

Mine is tucked up high and only has a dump tip under the body you cant see the outlet from behind unless you get under.

Basically at this point your done, I may have missed a step or 2 but its mostly there, from here we tow it to Gas research to get it fitted with a throttle body and converter under the grant $2000 of the install price.

Before anyone bags out there gear, probably not worth telling me I have used it on my own cars and customer cars for years and love it.

As already stated, metering of the gas comes from a Gas Research carby. The huge benefit this carby has over the rest of the products is that it not only regulates the air into the engine, but meters the amount of gas at the same time. Nearly (if not) all other products only meter the air and "hope" to get the gas mixture right. (Not speaking about injector systems of course). Here's the carby and converter....

At this point we change the spark plugs and fit 9mm ICE leads, if you are running a factory wastegate actuator you will need a bleed valve to raise the boost. These basically let pressure out of the waste gate actuator causing it to open less and therefore make more boost.

Finished

With it all together we fire it up and run it to 10PSI only as its a High Comp motor, I couldnt hang around to see the power figures and havent picked the dyno sheet up yet, but the end result on the road speaks for its self.

The car now has more power off boost, can be driven at lower revs without surging, runs 0-100km/h in 6.2 seconds. This is with very conservative timing as the distributor has not been re-curved yet. It will do standstills or doughies like its wet

For those of you who have driven up princess highway to labourtouce (spelling) and found the hills a struggle, well this applies no more, with the 35's recovery gear, eski, passenger full gas tank etc I can leave it in 5th and just walk over the hills. No more dropping to 3rd and holding 4500rpm.

General manners day to day are awesome no different to b4 except it has more power even off boost.

In terms of economy it betters my mates identical non turbo car by 10litres at the end of the day and because it was my first day after completion i was abusing it really badly. We are converting his starting in a week or 2.

Below I will put the completed Pics and some vids, I will no doubt have left a few steps out but if you have specific question just ask, I have nothing I wish to hide about this install.

Link below 0-160km/h

http://www.youtube.com/watch?v=gwnpV7Olzjo

Link below standstill on road bonnet open turbo glowing

http://www.youtube.com/watch?v=OlJJiTs-mvU

Link below quick squirt in first and second

http://www.youtube.com/watch?v=wFlz9uyS3Dw

its 2 AM and I'm using a borrowed keyboard because i though mine might like some beam and coke earlier in the week, if things don't make sense its cause I haven't slept for a while. Let me know and I will edit things.

Car Specs

1992 GQ LWB Wagon

2.2 ton unloaded

RB30 Carby motor

9.2 to 1 static compression

Running Bunsen burner/BBQ ring gas system.

4.3 Diff ratios

5 speed manual

100kw at Flywheel

2 inch body lift

2 inch spring lift

52kw at Rear Wheels

0-100 in 15.6 seconds

1/4 Mile in 20.6 seconds

Top speed on 31 inch tyres 132kph after approx 2km of flat out in 4th

All stock, no exhaust mods no internal mods.

OK so I started with this:

Now what we do is remove everything, intake manifold, exhaust manifold, charcoal canister all fuel and pollution equipment, and there is a lot of this shit as it was hard to make the GQ comply with ADR's with a carby. Of course for those of you who dont know they ran carby instead of injection like the VL and R31 Skyline as they somehow apparently got a better torque spread with carby.

Next step was to Source a VL or Skyline intake manifold, for those of you contemplating this don't waste your money on a genuine turbo manifold there not as good. A lot of guys fit the longer runner N/A manifold to there VL's and make more power over wider rev band. You can source the N/A intake for $20 or less.

You then buy six 18mm welsh plugs and JB weld them (JB weld is a super strong resin) into the injector holes (disregard this if you are running it on petrol and keeping the injection you will need these bosses).

I also stripped of the EGR valves, warmer pipes, fuel rail and reg and anything else EFI or pollution related, most holes where covered with 1.5mm tin and bolted using original holes.

Next bit is to fit it up, using new gaskets and your laughing should start looking like this:

Next step fitting the new exhaust manifold, I choose to go High mount for a few reasons.

1. No engine mount or body mods.

2. I can remove turbo in about 15 minutes everything is easy to get to.

3. its out of the water and mud, yes it still gets some but not submerged so no cracked housings.

4. Huge runners, fast spool times, plenty of room for head and cam mods later.

Pics below.

Don't bet getting excited by how pretty it looks after 5 minutes they go all different colors, and you can hardly see them.

The Turbo

I have chosen to use a Garrett T3 as originally used on VL's. I have had it completely rebuilt including new core, wheels shaft and all seals bearings etc. So its brand new inside. It is running a newer style front wheel which produced lower air temps on the compressor side and flows better at higher revs. Basically like High Flowing but without going over the top.

It still runs standard rear wheel so it spools early and hard, also has fantastic throttle response, no lag great combo. These are a direct bolt up for the manifold as they use the T3 flange.

The waste gate can be done one of two ways, the easy way and the cheap way.

Easy way is to get a blank flange and bolt it to the back of the turbo and run your exhaust from that. On the high mount manifolds they have a 7th runner for an external gate, you bolt it on and youre done.

The cheap way (fine for 15PSI or less) is to take the VL dump pipe and cut it off so only the gate is left, you then weld a 3 inch flange to this so you can bolt your exhaust onto it. You cant use the VL dump pipe stock as once you high mount your turbo its upside down, so a stock dump pipe would go through your bonnet and over the car.

Because the turbo is upside down you also need to fit the waste gate to the opposite side. I made a bracket from angle iron and just kept grinding till it was nice

Pic below shows the lines and modified wastegate, the gate is not the prettiest thing in the world but makes the same power as a $200-$300 custom one.

In the below photo you can see the 3 braided lines that feed oil pressure and water in and out of the turbo. There is a 4th steel tube mounted on the bottom that gravity feeds hot oil back to the sump.

The lines are pretty expensive part of the conversion, looking at $400 just for 3 lines and the drain

As far as I know patrols all use the late style RB30 blocks that have oil and water feeds and returns already there. Series 1 VL commodores don't have these feeds so check b4 you buy your next block.

Next step is to mount the intercooler, for this I have chosen a 600X300X75mm unit, it is a dual pass, bar and plate unit so what happens is the air enters hot through the bottom hose, goes across the cooler then up at the end tank and back through for a second pass. Its like having 2 coolers one on top of the other. These are a little more than traditional coolers but at $250 no a huge investment.

These are very effective coolers providing you don't get one thats too small for your application. Mine pulls so much heat out the top half of the cooler never even gets warm.

To bolt it up its simply 4 bits of flat steel or in my case aluminum bent 90 degrees and bolt through the radiator support panel and lower support rail.

You now need to cut two 100mm holes in the support panel to allow for the cooler pipes to pass through these are easy to mark once the cooler is in place. I then cut come old fuel hose long ways and stuck it around the holes before placing the silicone joiners in.

The joiners are worth a fortune I found a great place on the net selling good ones for great prices, much better than I could get even at trade.

By now you should be looking like this:

Next is the fun part.....I wanted it to look stock..So instead of gutting the grill I got the grinder out and spent 2 hours grinding the back of the grill till there was nothing left. The end result is being able to fit the grille with all horizontal bars intact and looking like factory.

If you want the world to know your packing boost disregard above step and chop ya grill up fully hektic styles

End result should be like this:

Are we there yet????

Not quite but not long to go......

Next step is the cooler pipes, from the turbo outlet to the cooler I used 2.5 inch as the turbo is only about 45mm exit diameter, from the cold side of the cooler to the throttle body I ran 3 inch as thats the carby size and cooler outlet size.

POD Filter was only temporary and has now been replaced with an Airbox as pictured.

Should now be looking like this :

At this point youre nearly done....

Next point is to either buy 3 inch mandrels and make a new exhaust or go and get one custom made. Mine is 3 inch from the dump pipe back running 1 straight through muffler, at cruise speeds you wouldn't even know it has an exhaust under acceleration you can just tell, for me its perfect as I an a V8 boy I hate the sound of a 4 or 6 with sports system so the less I hear it the happier I am.

Mine is tucked up high and only has a dump tip under the body you cant see the outlet from behind unless you get under.

Basically at this point your done, I may have missed a step or 2 but its mostly there, from here we tow it to Gas research to get it fitted with a throttle body and converter under the grant $2000 of the install price.

Before anyone bags out there gear, probably not worth telling me I have used it on my own cars and customer cars for years and love it.

As already stated, metering of the gas comes from a Gas Research carby. The huge benefit this carby has over the rest of the products is that it not only regulates the air into the engine, but meters the amount of gas at the same time. Nearly (if not) all other products only meter the air and "hope" to get the gas mixture right. (Not speaking about injector systems of course). Here's the carby and converter....

At this point we change the spark plugs and fit 9mm ICE leads, if you are running a factory wastegate actuator you will need a bleed valve to raise the boost. These basically let pressure out of the waste gate actuator causing it to open less and therefore make more boost.

Finished

With it all together we fire it up and run it to 10PSI only as its a High Comp motor, I couldnt hang around to see the power figures and havent picked the dyno sheet up yet, but the end result on the road speaks for its self.

The car now has more power off boost, can be driven at lower revs without surging, runs 0-100km/h in 6.2 seconds. This is with very conservative timing as the distributor has not been re-curved yet. It will do standstills or doughies like its wet

For those of you who have driven up princess highway to labourtouce (spelling) and found the hills a struggle, well this applies no more, with the 35's recovery gear, eski, passenger full gas tank etc I can leave it in 5th and just walk over the hills. No more dropping to 3rd and holding 4500rpm.

General manners day to day are awesome no different to b4 except it has more power even off boost.

In terms of economy it betters my mates identical non turbo car by 10litres at the end of the day and because it was my first day after completion i was abusing it really badly. We are converting his starting in a week or 2.

Below I will put the completed Pics and some vids, I will no doubt have left a few steps out but if you have specific question just ask, I have nothing I wish to hide about this install.

Link below 0-160km/h

http://www.youtube.com/watch?v=gwnpV7Olzjo

Link below standstill on road bonnet open turbo glowing

http://www.youtube.com/watch?v=OlJJiTs-mvU

Link below quick squirt in first and second

http://www.youtube.com/watch?v=wFlz9uyS3Dw