Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Bent axle housing

Bent axle housing

Hi everyone,

I've just noticed my rear axle housing was bent (the top of the rear tyres face inwards) and I'd need some advice on how to unbend it. I intend to remove the diff, axles and everything but I have no idea on how to do it properly.

Has this happened to anyone before and how did you go about fixing it, apart from changing the whole thing?

Any info would be greatly appreciated.

Thanks!

Cheers,

I've just noticed my rear axle housing was bent (the top of the rear tyres face inwards) and I'd need some advice on how to unbend it. I intend to remove the diff, axles and everything but I have no idea on how to do it properly.

Has this happened to anyone before and how did you go about fixing it, apart from changing the whole thing?

Any info would be greatly appreciated.

Thanks!

Cheers,

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

The axle tubes often rust and become weak at the u bolt mount point.

I had a bent one, repair was done, but didn't last long.

2nd solution was another housing, but strengthened at that point.

Mines 1.0 nt so this could be different.

Have no idea on straightening, but do know that could weaken it more, if done wrong.

some people weld in new tubes of thicker tube

christover

I had a bent one, repair was done, but didn't last long.

2nd solution was another housing, but strengthened at that point.

Mines 1.0 nt so this could be different.

Have no idea on straightening, but do know that could weaken it more, if done wrong.

some people weld in new tubes of thicker tube

christover

4WD SUZUKI CLUB VICTORIA

http://www.vic.suzuki4wd.com/forum/

http://www.vic.suzuki4wd.com/forum/

Thanks for all that. Rusting around the U bolts is not an issue since it's a coily model and getting a second hand one near impossible as Suzuki parts never last long at the wreckers here. A lot of people actually buy parts as soon as they are available even if they don't need them.

This said, the axle is not out by much, maybe a couple of degrees (around half an inch at the top of the tyres as far as I can see), which is why I would've wanted to unbend it and then strengthen it big time.

Also, I'm planning to buy an Airlocker during a trip to Australia early next year and I don't want to risk putting that in if the axle isn't straight.

This said, the axle is not out by much, maybe a couple of degrees (around half an inch at the top of the tyres as far as I can see), which is why I would've wanted to unbend it and then strengthen it big time.

Also, I'm planning to buy an Airlocker during a trip to Australia early next year and I don't want to risk putting that in if the axle isn't straight.

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

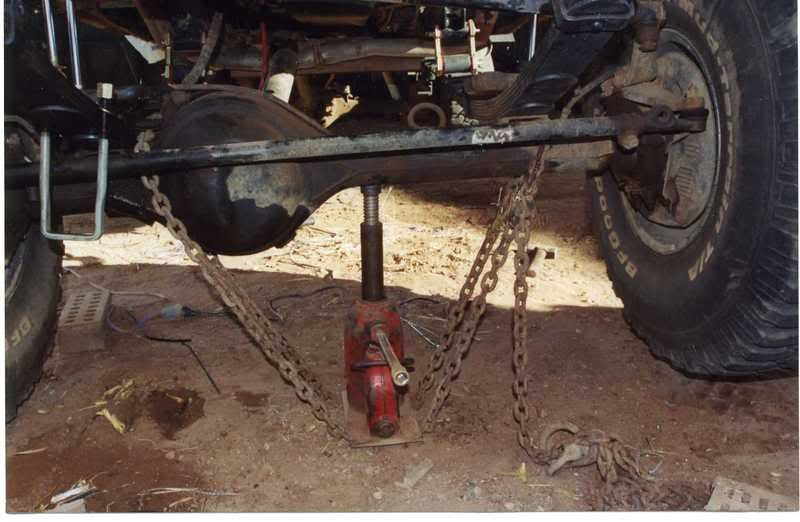

my mate did a bent diff repair with using a 10 tonne bottle jack and chains. basically use jack in middle and chains either onto ends or through it and then jack up to un bend.

[url=http://www.outerlimits4x4.com/viewtopic.php?p=930942#930942&highlight=]Zook[/url]

U SUK Zook Built and Sold.

New rig is 97 80 DX. 2" list 33s

U SUK Zook Built and Sold.

New rig is 97 80 DX. 2" list 33s

Thanks Nicbeer, great idea, will try that on the weekend.

Then I'll strengthen the lot with 8mm plate steel that I'll weld above and under the diff.

Might also take the opportunity of having the axle off the car and apart to see about changing the whole suspension setup...

Cheers,

Then I'll strengthen the lot with 8mm plate steel that I'll weld above and under the diff.

Might also take the opportunity of having the axle off the car and apart to see about changing the whole suspension setup...

Cheers,

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

8mm plateZookNC wrote:Thanks Nicbeer, great idea, will try that on the weekend.

Then I'll strengthen the lot with 8mm plate steel that I'll weld above and under the diff.

Might also take the opportunity of having the axle off the car and apart to see about changing the whole suspension setup...

Cheers,

Nic, thank you for the photo. I forgot to mention I also have oil seeping around the panhard rod bracket area which I've rewelded twice already so I'm thinking the bend might be there as well, but that's another story. I'll know once I've removed the axles, which I will do today.

Either way, the bottle jack and chains as pictured is the best idea I've seen so far, thanks for posting it up !

I'll let everyone know how I go.

Cheers,

Either way, the bottle jack and chains as pictured is the best idea I've seen so far, thanks for posting it up !

I'll let everyone know how I go.

Cheers,

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

i had a mate that used chain an jack on a coily to straighten it, but they just bend again, u can use some rhs an cut an grind into shape of top off diff an weld on, it is normaly the long side of diff that bends, also check your trail arm mounts on diff i ripped mine clean off!

chicks dig panel damage

Pazz, thanks for the advice. I'd planned on welding a length of 8mm plate steel at right angles with the diff on the top side as you suggest once it's straightened but RHS might be a better proposition. I also intend to change the suspension setup to 4 link in the future so I'll be using this for the top link as well.

As for the radius arm brackets, I've already torn one so they've been strengthened already but thanks for the info.

Planning to fit 31's in the future too so I need a strong enough diff for the side loads it will be copping.

This said, I never thought I'd get so many answers in such a short period of time so thank you again to everyone who has replied!

As for the radius arm brackets, I've already torn one so they've been strengthened already but thanks for the info.

Planning to fit 31's in the future too so I need a strong enough diff for the side loads it will be copping.

This said, I never thought I'd get so many answers in such a short period of time so thank you again to everyone who has replied!

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

8 mm will be nightmare to work with. 3mm would be heaps. Have a look at some of the trusses on Pirate 4X4- they mostly use 2-3mm sheet and use box sections, dimple dies etc to build the strength.

Be VERY CAREFUL with heat and technique - I have bent a housing by welding a truss on it. Odds are, you'll need to straighten it after you have finished welding onto it.

Steve.

Be VERY CAREFUL with heat and technique - I have bent a housing by welding a truss on it. Odds are, you'll need to straighten it after you have finished welding onto it.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Thanks Steve,

My idea with the 8mm plate was to use a strip that I would grind to the shape of the housing and weld it on its edge. I was also planning to chain down the housing somehow before welding so it doesn't bend or warp.

What do you think ?

Thanks,

My idea with the 8mm plate was to use a strip that I would grind to the shape of the housing and weld it on its edge. I was also planning to chain down the housing somehow before welding so it doesn't bend or warp.

What do you think ?

Thanks,

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

Well, as far as technique goes, I'm planning to use an inverter-type stick welder with 2.5mm rod, so I would've thought heat wouldn't have been so bad. On top of which I intend to weld it bit by bit and let everything cool right down between welds.

What do you guys think ?

What do you guys think ?

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

It will bend. you will be much better to use some much thinner material and make it into a box section. The amount of heat required to ensure fusion into 8mm plate will cause significant distortion, and excess heat is always going to be a problem with stick.ZookNC wrote:Well, as far as technique goes, I'm planning to use an inverter-type stick welder with 2.5mm rod, so I would've thought heat wouldn't have been so bad. On top of which I intend to weld it bit by bit and let everything cool right down between welds.

What do you guys think ?

I'm going to be trussing my diffs in the new ywar and I'm planning to use about 2mm sheet. The strength comes from triangulation and multiple planes, not from weight of material.

I agree, TIG would be the way to go, but failing that, mig and "tack-tack tack" welding, whilst not good practice, will limit heat input and shoudl restrict distortion. Be prepared to have to straighten it in any case after welding though.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Thanks Steve, I think I'll follow your advice and buy a length of RHS which I can get in 2 or 3mm here if I'm not mistaken.

I'll probably end up spot welding the truss at first and then welding short strips in between the spots going from one side of the housing to the other and back.

I'll probably be doing all this mid January as I'll be in Sydney for a couple of weeks around New Year's Eve and I'll definitely be bringing back a heap of goodies for the Zook!

Cheers,

I'll probably end up spot welding the truss at first and then welding short strips in between the spots going from one side of the housing to the other and back.

I'll probably be doing all this mid January as I'll be in Sydney for a couple of weeks around New Year's Eve and I'll definitely be bringing back a heap of goodies for the Zook!

Cheers,

Froggy

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

98 Sierra / Samurai

2 inch suspension lift

Warn winch

Lots of "home made" accessories

Oh, and a Mazda BT-50 dual cab ute...

Who is online

Users browsing this forum: No registered users and 14 guests