Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Water flow tech for water to air intercooler

Moderators: toaddog, TWISTY, V8Patrol, Moderators

Water flow tech for water to air intercooler

Guys anyone with experience of water flow technology give some clarity to my thoughts one way or the other.

I am making a water to air intercooler as I cannot afford the laminova route and can't justify spending that moeny on a truck that is lucky to do about 5,000k's a year.

I am jacketing an air to air core and was thinking of just putting diverter flaps on the inside so the water flows through in a triple pass affect like a triple flow radiator. eg split the core into 3 sections(figurately speaking), water flows into and thrrough top section down into middle section and then back up into top section and out so it snakes through a third of the core each time. I want to make sure though that I do get fairly even water flow and I would assume without any diverters the water would drop in and mostly flow through the first part of the core and out and not necessarily get to the back.

The core is about 400 long x 200 wide and I was planning to run the diverters length wise as it splits the number of core tubes up nicely into 3 sections. Again in relation to water flow would it work best to run the diverters across the short width in a certain sequence. Basically I want to get as even a flow as possible as I know water will take the path of least resistance if not helped.

Please don't start telling me I'm better off with an air to air set up or an off the shelf PWr or something as that's not what this is all about.

I am making a water to air intercooler as I cannot afford the laminova route and can't justify spending that moeny on a truck that is lucky to do about 5,000k's a year.

I am jacketing an air to air core and was thinking of just putting diverter flaps on the inside so the water flows through in a triple pass affect like a triple flow radiator. eg split the core into 3 sections(figurately speaking), water flows into and thrrough top section down into middle section and then back up into top section and out so it snakes through a third of the core each time. I want to make sure though that I do get fairly even water flow and I would assume without any diverters the water would drop in and mostly flow through the first part of the core and out and not necessarily get to the back.

The core is about 400 long x 200 wide and I was planning to run the diverters length wise as it splits the number of core tubes up nicely into 3 sections. Again in relation to water flow would it work best to run the diverters across the short width in a certain sequence. Basically I want to get as even a flow as possible as I know water will take the path of least resistance if not helped.

Please don't start telling me I'm better off with an air to air set up or an off the shelf PWr or something as that's not what this is all about.

fester, you're right, you will need some kind of way to control your water flow.

If I were doing this I'd make some diverter baffles, essentially folded plates with a short fold that will direct the water through the fins between the tubes so that it covers the maximum core area.

I'm assuming you want to direct the air the same as normal, through the tubes?

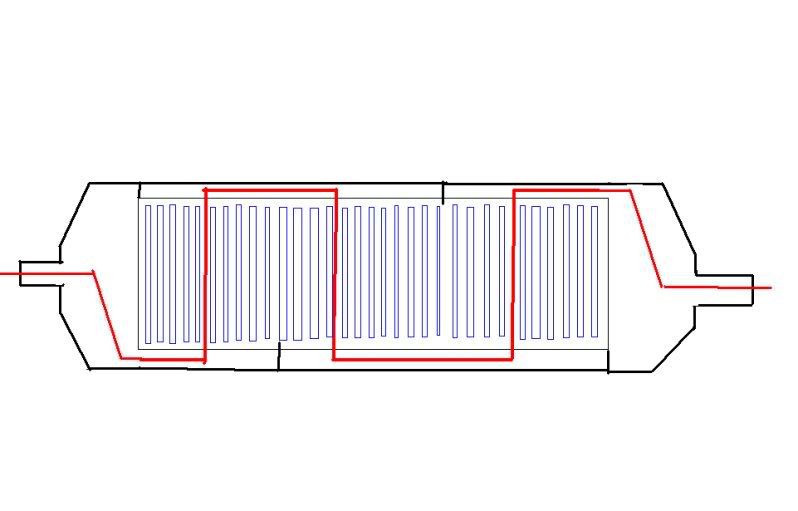

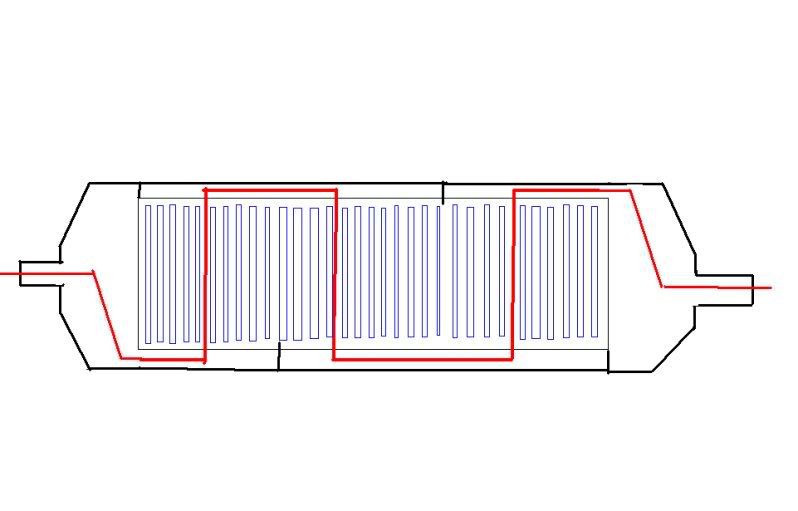

Something along the lines of what I've drawn perhaps? Please forgive my effort with Paint, it's not exactly my forte.

Regards Andrew.

If I were doing this I'd make some diverter baffles, essentially folded plates with a short fold that will direct the water through the fins between the tubes so that it covers the maximum core area.

I'm assuming you want to direct the air the same as normal, through the tubes?

Something along the lines of what I've drawn perhaps? Please forgive my effort with Paint, it's not exactly my forte.

Regards Andrew.

We are Tig welders, gravity doesn't worry us.

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

[img]http://www.studmonkeyracing.com/forums/smilies/weld.gif[/img]

With the baffles/3-pass arrangement it would be important for those baffles to be very failure proof since, if they fail once it's all put together, the water will bypass a whole section of the intercooler.

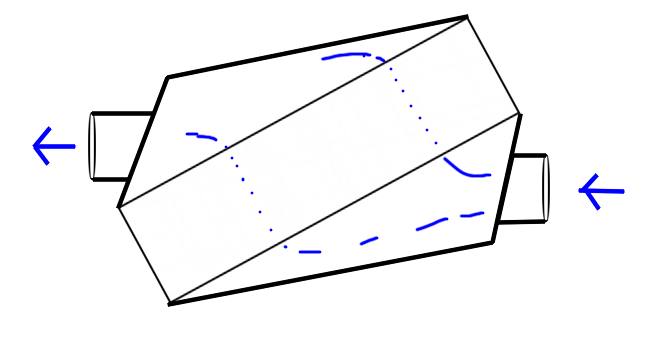

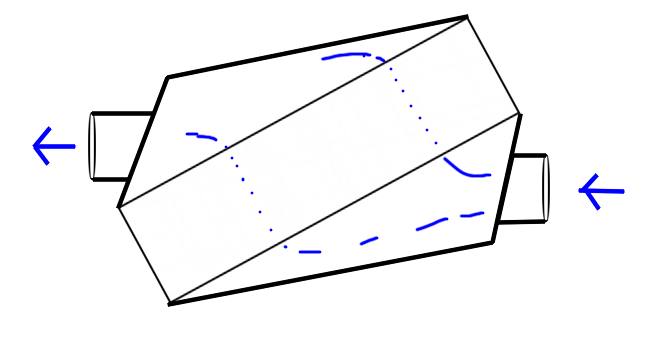

Short of bench testing lots of different arrangements it's all gut feel, my gut feel would make me go for a single-pass set-up if possible. (I have fooled around with two-pass and one-pass setups like this with air flow but not water flow in a totally different context). But basically I just think the water is going to have no hope of running through anything less than the whole intercooler with a sensible single-pass set-up, unless you are flowing too little water anyway.

eg.

What I am trying to illustrate here is a single-pass arrangement where there is inherently no shortcut for the water flow.... especially if the water inlet and outlet are at opposite ends.

Just an idea, probably stupid, and obviously size and shape are issues to consider too. I was almost too scared to comment because there are so many people here who know a lot about turbos.

Short of bench testing lots of different arrangements it's all gut feel, my gut feel would make me go for a single-pass set-up if possible. (I have fooled around with two-pass and one-pass setups like this with air flow but not water flow in a totally different context). But basically I just think the water is going to have no hope of running through anything less than the whole intercooler with a sensible single-pass set-up, unless you are flowing too little water anyway.

eg.

What I am trying to illustrate here is a single-pass arrangement where there is inherently no shortcut for the water flow.... especially if the water inlet and outlet are at opposite ends.

Just an idea, probably stupid, and obviously size and shape are issues to consider too. I was almost too scared to comment because there are so many people here who know a lot about turbos.

This is not legal advice.

All of the large airconditioning chilled water coils and heating water coils I have ever seen are multiple pass units. Although these run the opposite to what you want to do; the water is in the coil and the air goes around the outside. Same principle of heat transfer though.

It is important the air and water run in different directions. i.e. the coldest water is at the air leaving side.

Hydronics and heat transfer etc. is a very complex subject that I have only a very basic knowledge in. Other than trying different configurations I think it will be gut feel as chimpboy said

Dazza

It is important the air and water run in different directions. i.e. the coldest water is at the air leaving side.

Hydronics and heat transfer etc. is a very complex subject that I have only a very basic knowledge in. Other than trying different configurations I think it will be gut feel as chimpboy said

Dazza

Thanks for the input guys all good. Andrew your drawing is actually better than mine otherwise I would have put something up myself. My initial thoughts are like Andrew has drawn except the intercooler in question is a ford xr6 core so it is about 500 long by 180 wide but the tubes run lengthwise not across as per Andrews drawing. But his principal was what I was thinking only because it seemed the easiest to do without testing and in my mind had the potential to spread the flow. The only reason I suggested a triple pass was that that number split the core equally with the same number of tubes per section. I alos thought any more diverters than that may slow the water too much and create other problems.

chimpboy your design is another I have contemplated and the thinking in that was to mimic intercooler inlets that are often tapered I presume to even flow out. I presume they have the large end of the taper nearest the opening and tapering to shallow furthest away but I'm not sure if this is for even distribution of airflow speed.

I know I need something and either will be easy for me to do, I can weld the diverters in before the jacket is welded up just not sure which is actually best.

Also Dazza the shape and orientation of the core will allow opposing flows with air flowing lengthwise and water flowing across the core.

What I wasn't also sure of was whether the long water sections would be a problem and whether I actually need a diverterto get the water alon the length of the core in case it might all drop through just near the entry and not circulate to the ends correctly. To that end I also contemplated runnign the water in the same direction as the air as the chambers for want of a better word would be shorter and maybe spread out better but that imposes other possible problems with many more diverter sections along the length and also should the cold water flow in near the hot air or furthest away. If it flows at the hotest point does it loose too much cooling towards the exit end.

My concern with even flow is derived from experience with a water feature I made at work. By all accounts I expected I had slowed the flow enough to be even but it was not perfect. The design was a RHS box with mitred corner joins, the water entered the bottom piece of box in the middle, had to go up the sides and then across the top. A series of holes was made in the top edge of the top box, then a channel cover was welded to the the top of the top box giiving about a 3mm gap along the top and front edge. The water was supposed to fire up hit the channel and then cascade down the front in an even sheet. Needless to say I found out that the bulk of the flow still came out stronger at the outer edges and not even along the face.Then I put another diverter inside the channel so the water had to go backwards then over the diverter, through the small gaps and out. Much better but still not the perfect sheet effect.

Anyway you can see why I am concerned about getting it right. ?If I had the money I'd go Laminova all the way but even with weldign it all up myself the budget won;t allow. I know my design will not be as efficient as Andrew's and Matt's so I need to get the water flow as perfect as I can. The only other time consuming way of working it out for me would be to make the jacketing out of perspex so I can see what the water does but as long as I can get a handle on basic water flow principals I'm sure it can be done without too much fuss.

chimpboy your design is another I have contemplated and the thinking in that was to mimic intercooler inlets that are often tapered I presume to even flow out. I presume they have the large end of the taper nearest the opening and tapering to shallow furthest away but I'm not sure if this is for even distribution of airflow speed.

I know I need something and either will be easy for me to do, I can weld the diverters in before the jacket is welded up just not sure which is actually best.

Also Dazza the shape and orientation of the core will allow opposing flows with air flowing lengthwise and water flowing across the core.

What I wasn't also sure of was whether the long water sections would be a problem and whether I actually need a diverterto get the water alon the length of the core in case it might all drop through just near the entry and not circulate to the ends correctly. To that end I also contemplated runnign the water in the same direction as the air as the chambers for want of a better word would be shorter and maybe spread out better but that imposes other possible problems with many more diverter sections along the length and also should the cold water flow in near the hot air or furthest away. If it flows at the hotest point does it loose too much cooling towards the exit end.

My concern with even flow is derived from experience with a water feature I made at work. By all accounts I expected I had slowed the flow enough to be even but it was not perfect. The design was a RHS box with mitred corner joins, the water entered the bottom piece of box in the middle, had to go up the sides and then across the top. A series of holes was made in the top edge of the top box, then a channel cover was welded to the the top of the top box giiving about a 3mm gap along the top and front edge. The water was supposed to fire up hit the channel and then cascade down the front in an even sheet. Needless to say I found out that the bulk of the flow still came out stronger at the outer edges and not even along the face.Then I put another diverter inside the channel so the water had to go backwards then over the diverter, through the small gaps and out. Much better but still not the perfect sheet effect.

Anyway you can see why I am concerned about getting it right. ?If I had the money I'd go Laminova all the way but even with weldign it all up myself the budget won;t allow. I know my design will not be as efficient as Andrew's and Matt's so I need to get the water flow as perfect as I can. The only other time consuming way of working it out for me would be to make the jacketing out of perspex so I can see what the water does but as long as I can get a handle on basic water flow principals I'm sure it can be done without too much fuss.

If you combine Andrews drawign with mine you get the idea of my initial thought better. Think of my drawing in plan view - the water comes int eh first chamber on top through middle chamber back up, into third chamber and back down to exit the bottom rear. Concerned about evening the flow along the length or whether the single flow tapered type would work better in this size and shape core.

sounds like someone is starting to think!

I just spent 14months doing consulting engineering and designwork on a similar project. The design has many national and OS patents, and is currently in negotiation with a large rad/cooler manufacturer. Obviously i am not allowed to say too much. but PM me as i 'might' be able to give you some hints!

I just spent 14months doing consulting engineering and designwork on a similar project. The design has many national and OS patents, and is currently in negotiation with a large rad/cooler manufacturer. Obviously i am not allowed to say too much. but PM me as i 'might' be able to give you some hints!

WWW.TEAMDGR.COM

WWW.SUPERIORENGINEERING.COM.AU

WWW.LOCKTUP4X4.COM.AU

WWW.SUPERIORENGINEERING.COM.AU

WWW.LOCKTUP4X4.COM.AU

Is a second hand water/air intercooler an option? Like one of the Subaru or Toyota ones?

I knocked up a dodgy idea that i had on paint:

This is looking at it from the side, blue being water, and the red markings being the air outlet and end cap. The three jacket/tanks on each side have there own feed nipple. Ignore the fact that the water jackets dont match up - there supposed to be equal thirds.

The idea is that instead of having one route, you can split it into three separate sections. The feed lines come from a three way Y-splitter, and equal length hoses (i assume) would remove the chance of "path of least resistance". If one section fails (leaks), you can disconnect it from the system.

No idea if its a valid idea though.

I knocked up a dodgy idea that i had on paint:

This is looking at it from the side, blue being water, and the red markings being the air outlet and end cap. The three jacket/tanks on each side have there own feed nipple. Ignore the fact that the water jackets dont match up - there supposed to be equal thirds.

The idea is that instead of having one route, you can split it into three separate sections. The feed lines come from a three way Y-splitter, and equal length hoses (i assume) would remove the chance of "path of least resistance". If one section fails (leaks), you can disconnect it from the system.

No idea if its a valid idea though.

Making some broad assumptions that are probably incorrect. 1MADEngineer is a real engineer, not a backyard yobbo like me, so he can prove his stuff up better I hope.

Here goes:

Water has a MUCH greater thermal mass than air.

So you need MUCH less water than air to acheive the same temp change.

BUT, as you are converting an existing intercooler, it's designed for air, therefore you'll have an "excess" of water in the core. This means that flow rate is far less critical due to the buffering effect of that volume of water. Further, low flow rates tend toward even flow patterns, as there are less eddy and flow effects. It's a pressure effect rather than viscosity / mass effect.

Now the goal is to cool the air somewhat. This reduces overall engine efficiency, but improves maximum power.

You only have to cool the "average" of the air. If every spot in the cooler is not working to maximum efficiency, that is easily overcome by having a larger cooler. With water in the core, I would guess that nearly any cooler will be able to give good performance. 3 Hyclones in series will mix it and give you enough power to drive through gravity. I reckon it'll mix just fine.

So - I wouldn't stress the flow pattern too much personally.

I would stress

a) A HUGE front cooler - and I would make it out of an old AC condensor.

b) Lower flow rate

c) 3 temp probes to test it out - pre intercooler, post intercooler, water temp.

I reckon almost any core you convert will get you to 50C from the I'm guessing 120ish you are at peaks atm.

Below 50 is hard without insualtion from engine bay temps.

What are you goign to use for a reliable water pump?

Catchya

Paul

Here goes:

Water has a MUCH greater thermal mass than air.

So you need MUCH less water than air to acheive the same temp change.

BUT, as you are converting an existing intercooler, it's designed for air, therefore you'll have an "excess" of water in the core. This means that flow rate is far less critical due to the buffering effect of that volume of water. Further, low flow rates tend toward even flow patterns, as there are less eddy and flow effects. It's a pressure effect rather than viscosity / mass effect.

Now the goal is to cool the air somewhat. This reduces overall engine efficiency, but improves maximum power.

You only have to cool the "average" of the air. If every spot in the cooler is not working to maximum efficiency, that is easily overcome by having a larger cooler. With water in the core, I would guess that nearly any cooler will be able to give good performance. 3 Hyclones in series will mix it and give you enough power to drive through gravity. I reckon it'll mix just fine.

So - I wouldn't stress the flow pattern too much personally.

I would stress

a) A HUGE front cooler - and I would make it out of an old AC condensor.

b) Lower flow rate

c) 3 temp probes to test it out - pre intercooler, post intercooler, water temp.

I reckon almost any core you convert will get you to 50C from the I'm guessing 120ish you are at peaks atm.

Below 50 is hard without insualtion from engine bay temps.

What are you goign to use for a reliable water pump?

Catchya

Paul

Lexus LX470 - hrrm Winter Tyres

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

Yes this is important for best efficiency. It is basic thermodynamics and most heat exchangers are designed this way.azzad wrote:...

It is important the air and water run in different directions. i.e. the coldest water is at the air leaving side.

...

Dazza

The way that fester2au showed in his sketch will be nowhere near as efficient.

John

I think the trouble is I never stop thinking, just sometimes I'm thinking in areas I have little experience with. Any hints would be appreciated as I'm just trying to make do with my limited budget and make it as good as I can within the constraints. Your commercial counterparts are safe from me, I would say my trade qualifications are not yet to the stage of tackling the mass manufacturing market just yet1MadEngineer wrote:sounds like someone is starting to think!

I just spent 14months doing consulting engineering and designwork on a similar project. The design has many national and OS patents, and is currently in negotiation with a large rad/cooler manufacturer. Obviously i am not allowed to say too much. but PM me as i 'might' be able to give you some hints!

Coxy I don't see any of the alredy produced water to air cores as suitable for my application nor cheeap enough. I think I will haev better surface area for both air and water with this core especially with fitting constraints. I need it narrow enouhg to mount towards the firewall above the rocker cover as my 80 series has a 1HD-FTE fitted and the hump in the rocker cover is in the middle not the back like other 1HD variants. I bought the XR6 core for $60and it's like new. Jacketing it will cost me time and a bit of digging in the scrap bin at work and a beer for the boss. I did think about the individual chambers design as you have drawn and this copies what Matt andAndrew are doing with the Laminova cores. However I didn't see yet, unless someone gives me good evidence, that the extra work and plumbing would really be that much better than a correctly flowed set up.coxy321 wrote:Is a second hand water/air intercooler an option? Like one of the Subaru or Toyota ones?

I knocked up a dodgy idea that i had on paint:

This is looking at it from the side, blue being water, and the red markings being the air outlet and end cap. The three jacket/tanks on each side have there own feed nipple. Ignore the fact that the water jackets dont match up - there supposed to be equal thirds.

The idea is that instead of having one route, you can split it into three separate sections. The feed lines come from a three way Y-splitter, and equal length hoses (i assume) would remove the chance of "path of least resistance". If one section fails (leaks), you can disconnect it from the system.

No idea if its a valid idea though.

Fester and Awills drawings have the water changing direction by 180deg twice to pass through the core, once you try to change the flow direction by more than 45 deg you add a lot more resistence (unless you can using large sweep bends) which will slow the flow, or require greater pressure working your pump harder.

I would be far more inclined to go for chimpboys sketch which sees direction changes of less than 90deg (see if you can get chimpboy to throw in some free atmospheric pressure to help things along)

coxys looks good too, straight flow, but a little more plumbing and more space required

i read somewhere that core design for air to air vs air to water is quite different. check out bell intercoolers and air to water cores (founded by Corky Bell I believe?) have a look around this site for some good snippets of tech.

air to air use long cores, air to water only need short pass for the air intake charge to dump its heat, for best efficiency spread the intake charge accross as many short passages as you can, and keep them as short as possible (think laminova)

long passages increase resistance and pressure drop, air drags and slows as it passes along the surface of each individual core, the shorter the better (provided you effectively exchange the heat)

I would be far more inclined to go for chimpboys sketch which sees direction changes of less than 90deg (see if you can get chimpboy to throw in some free atmospheric pressure to help things along)

coxys looks good too, straight flow, but a little more plumbing and more space required

i read somewhere that core design for air to air vs air to water is quite different. check out bell intercoolers and air to water cores (founded by Corky Bell I believe?) have a look around this site for some good snippets of tech.

air to air use long cores, air to water only need short pass for the air intake charge to dump its heat, for best efficiency spread the intake charge accross as many short passages as you can, and keep them as short as possible (think laminova)

long passages increase resistance and pressure drop, air drags and slows as it passes along the surface of each individual core, the shorter the better (provided you effectively exchange the heat)

me3@neuralfibre.com wrote:Making some broad assumptions that are probably incorrect. 1MADEngineer is a real engineer, not a backyard yobbo like me, so he can prove his stuff up better I hope.

Here goes:

Water has a MUCH greater thermal mass than air.

So you need MUCH less water than air to acheive the same temp change.

BUT, as you are converting an existing intercooler, it's designed for air, therefore you'll have an "excess" of water in the core. This means that flow rate is far less critical due to the buffering effect of that volume of water. As long as heat soak doesn't come into play. Further, low flow rates tend toward even flow patterns, as there are less eddy and flow effects. It's a pressure effect rather than viscosity / mass effect. Makes sense and maybe your sizing argument has merit in this case. I know my example of the water feature would affect this to a point as pressure was partly determined by the size of the holes for the flow, where I expect a compensation effect may from having large holes near the water entry and small towards middle or should that be the other way around.

Now the goal is to cool the air somewhat. This reduces overall engine efficiency, but improves maximum power.

You only have to cool the "average" of the air. If every spot in the cooler is not working to maximum efficiency, that is easily overcome by having a larger cooler. With water in the core, I would guess that nearly any cooler will be able to give good performance. 3 Hyclones in series will mix it and give you enough power to drive through gravity. I reckon it'll mix just fine.

So - I wouldn't stress the flow pattern too much personally.

I would stress

a) A HUGE front cooler - and I would make it out of an old AC condensor. Yes tossed up the ac core or maybe a radiator core out of a Honda car which fits over half the radiator area. The choice will come down partly to whether I want to retain the fan over the drivers side of the air con as this is a Sahara. There will definately be a shrouded fan over the water core.

b) Lower flow rate To a point so as not to create heat soak. Maybe a trade off to the volume of water in the system. Can also add a header tank of some sort if I really feel I need more volume. Thinking a little either side of 20 litres/minute based on some other info - Laminova boys, PWR web site.

c) 3 temp probes to test it out - pre intercooler, post intercooler, water temp. Certainly if I can do it cheaply, especially the pre/post to gauge results. Water temp is easy with any cheapish aftermarket temp gauge plumbed into water storage tank. Would probably hook up loosely in car till I see all is OK. May not monitor it forever if system seems reliable. Have a dislike for excessive gadgets around my cabin if they cannot be integrated fairly seemlessly. Read I had gauge pods and the like.

I reckon almost any core you convert will get you to 50C from the I'm guessing 120ish you are at peaks atm. For a budget install and for the amount of K's I do I would be happy with a result approaching that.

Below 50 is hard without insualtion from engine bay temps. Having said that I will be pricing the idea of HPC coating the intercooler and piping or for that matter I could heat wrap it all quite cheaply. Might not look flash but could work. Water hoses can be wrapped in the aluminium insulating tubing.

What are you goign to use for a reliable water pump? Good second hand Toyota/Suburu water to air pump. Maybe good second hand Davies Craig or a new one if they pop up cheap. PWR use and sell a Bosch one at the lower end of the market. The factory Mustang ones can be had not to expensively. Or possibly one of the non pressure pump irrigation type pumps. I think impellor pumps handle a bit of heat better or do the diaphram ones not usre about their flow rates yet.

Catchya

Paul

Hence my choice of core. It fits the space quite well where a short wide core would not. Didn't know but understand now why most water cores are pretty squat or square however in choosing a cooler I based the donor on units that are known to flow pretty well for OEM designs. I also have a Nissan GTiR core which rated well in flow tests and is squarer at about 300x280 bbut would need narrowing and not that much shorter. Given reasonable flow rates (air) hopefully the longer passages will allow better cooling through the water than a short core with not that much trade off. Still I wonder how comparable the flow resistance of my core shape would stack up against a front mount with the additional 5+ metres off piping. I also believe that a 90 deg bend adds something in the order of over a metre of straight pipe and given the number of bends in a Toyota air to air application would i really be loosing out against a true water to air core given the nature and design brief of my application.80's_delirious wrote:Fester and Awills drawings have the water changing direction by 180deg twice to pass through the core, once you try to change the flow direction by more than 45 deg you add a lot more resistence (unless you can using large sweep bends) which will slow the flow, or require greater pressure working your pump harder. Did cross my mind although not ideal in your terms the direction changes are all 90 deg not 180. This might be able to be traded against available pump flow. I guess maybe chimpboys design would allow a significantly lower flow rated pump

I would be far more inclined to go for chimpboys sketch which sees direction changes of less than 90deg (see if you can get chimpboy to throw in some free atmospheric pressure to help things along)???? chimpboy please explain

coxys looks good too, straight flow, but a little more plumbing and more space required Not a big deal all issues are able to be dealth with in available space I think. I had a thought similar to this with individual inlets but single common outlet to simplify a little.

i read somewhere that core design for air to air vs air to water is quite different. Yes I am aware of this also but I have also read of success per dollar spent with converting an air core amd I am not expecting to rival a truely R&D'd water/air with my budget in mind. However I am hopeful of worthwhile gains for the amount off driving this truck does. Lets face it plently of people put in big K's over time without any inlet cooling at all.[url=http://www.bellintercoolers.com/pages/techFAQ.html]check out bell intercoolers[/url] and air to water cores (founded by Corky Bell I believe?) have a look around this site for some good snippets of tech.

air to air use long cores, air to water only need short pass for the air intake charge to dump its heat, for best efficiency spread the intake charge accross as many short passages as you can, and keep them as short as possible (think laminova)

long passages increase resistance and pressure drop, air drags and slows as it passes along the surface of each individual core, the shorter the better (provided you effectively exchange the heat)

Is that VX import or Aussie Sahara. Thought the fan was necessity due to the extra volume with the rear air con.80's_delirious wrote:for your front heat exchanger/radiator look at AU falcon radiator, they are readily available and can be got dirt cheap and they are almost the same size as the cruiser radiator. ditch the A/C fan, my A/C (VX 80series )used to just about give me frost bite and it has no fan

Is that actually falcon radiator or ac core. I take it the ford rad is quite slim if that's what you suggest. I've seen others at the wreckers also that caught my eye. Many large surface area with single core . That might be a better idea as I have a couple of small thermos lying around so I could use a pair on the front of the core. One could possibly still be triggered by the air con but no sure if that would actually acheive anything for air con performance but wouldn't hurt intercooler performance as air con would almost always be used in the same circumstances that max intercooler performance was also required.

Just a bit paranoid about air con performance at the moment as mine doesn't work and needs addressing once I reapir some minor fron end damage. ( need to degas to get radiator support out and back in then regas and get a/c checked fully)

mine's an import so no rear air.fester2au wrote:Is that VX import or Aussie Sahara. Thought the fan was necessity due to the extra volume with the rear air con.80's_delirious wrote:for your front heat exchanger/radiator look at AU falcon radiator, they are readily available and can be got dirt cheap and they are almost the same size as the cruiser radiator. ditch the A/C fan, my A/C (VX 80series )used to just about give me frost bite and it has no fan

Is that actually falcon radiator or ac core. I take it the ford rad is quite slim if that's what you suggest. I've seen others at the wreckers also that caught my eye. Many large surface area with single core . That might be a better idea as I have a couple of small thermos lying around so I could use a pair on the front of the core. One could possibly still be triggered by the air con but no sure if that would actually acheive anything for air con performance but wouldn't hurt intercooler performance as air con would almost always be used in the same circumstances that max intercooler performance was also required.

Just a bit paranoid about air con performance at the moment as mine doesn't work and needs addressing once I reapir some minor fron end damage. ( need to degas to get radiator support out and back in then regas and get a/c checked fully)

I was refering to AU engine radiator. i have one sitting in the garage waiting for me to get inspired to do similar to what you are contemplating. I have already modified the thermos and shroud ready to fit the 80series radiator, its a very close match in terms of size (let me know if you want some dimensions)

I had similar ideas to yourself in regard to converting an air to air core, it would be great to know how successful it may be. I like the idea of the laminova gear but cant justify the cost.

Hi Fester - have you read all the stuff on ARE's website?

http://www.are.com.au/feat/techt/airwaterinter.htm

and the other pages.

Personally, I would make the under bonnet cooler as large as possible for air contact area, and the front one as wide and thin as possible - single thin core.

I would pretty well ignore the water flow apart from making sure it was flowing at a reasonable rate.

After that = temp probe to see if I stuffed up :)

Catchya

Paul

http://www.are.com.au/feat/techt/airwaterinter.htm

and the other pages.

Personally, I would make the under bonnet cooler as large as possible for air contact area, and the front one as wide and thin as possible - single thin core.

I would pretty well ignore the water flow apart from making sure it was flowing at a reasonable rate.

After that = temp probe to see if I stuffed up :)

Catchya

Paul

Lexus LX470 - hrrm Winter Tyres

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

G'day Fester,

take a look at www.frozenboost.com, there in the USA but have air to water cores and heat exchangers pretty cheap. Well when I got mine the Aussie dollar was a bit better and the core, heat exchanger, and BOSCH water pump cost me just under $800.00 AUD.

take a look at www.frozenboost.com, there in the USA but have air to water cores and heat exchangers pretty cheap. Well when I got mine the Aussie dollar was a bit better and the core, heat exchanger, and BOSCH water pump cost me just under $800.00 AUD.

Raiding old washing machines?chimpboy wrote:Do you have room for a belt-driven pump rather than an electric pump? If you can squeeze one onto the engine you might get away a bit cheaper (and it will be grunty).

Paul

Lexus LX470 - hrrm Winter Tyres

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

Gone - Cruiser HZJ105 Turbo'd Locked & Lifted

Gone - 3L Surf

The subaru impreza w2a IC can be had for that money on ebay, including pump, cooler and radiator.fester2au wrote:Thanks Rob, I'll do a google and check it out that link doesn't work. However if I can;t make this for under about $350-$400 it isn't going to happen and it will if I can find a cheap pump.

Dazza

me3@neuralfibre.com wrote:Raiding old washing machines?chimpboy wrote:Do you have room for a belt-driven pump rather than an electric pump? If you can squeeze one onto the engine you might get away a bit cheaper (and it will be grunty).

Paul

No I was thinking of something like:

This is not legal advice.

God Of Emo

Posts: 7350

Joined: Sun Aug 24, 2003 7:04 pm

Joined: Sun Aug 24, 2003 7:04 pm

Location: Newy, home of the ZOOK (Rockin the 'diff)

Contact:

azzad wrote:The subaru impreza w2a IC can be had for that money on ebay, including pump, cooler and radiator.fester2au wrote:Thanks Rob, I'll do a google and check it out that link doesn't work. However if I can;t make this for under about $350-$400 it isn't going to happen and it will if I can find a cheap pump.

Dazza

That will be the RS liberty water to air intercooler, the WRX has a top mounted air to air intercooler. I own an RS liberty, the WAIC is okay, but nothing flash. There are some upgrades that can be done, but overall they do limit power to about 190kw at all four wheels.

Layto....

[quote="v840"]Just between me and you, I actually really dig the Megatwon, but if anyone asks, I'm going to shitcan it as much as possible! :D[/quote]

my bad, thats what I meant, brain going to fast for fingers on the keyboardlay80n wrote:azzad wrote:The subaru impreza w2a IC can be had for that money on ebay, including pump, cooler and radiator.fester2au wrote:Thanks Rob, I'll do a google and check it out that link doesn't work. However if I can;t make this for under about $350-$400 it isn't going to happen and it will if I can find a cheap pump.

Dazza

That will be the RS liberty water to air intercooler, the WRX has a top mounted air to air intercooler. I own an RS liberty, the WAIC is okay, but nothing flash. There are some upgrades that can be done, but overall they do limit power to about 190kw at all four wheels.

Layto....

Haha if I can put down 190kw at the wheels either rear or all four I'd be pretty stoked. Looked at the Liberty ones a while ago but for my mind doesn't lend itself that well to my layout.lay80n wrote:azzad wrote:The subaru impreza w2a IC can be had for that money on ebay, including pump, cooler and radiator.fester2au wrote:Thanks Rob, I'll do a google and check it out that link doesn't work. However if I can;t make this for under about $350-$400 it isn't going to happen and it will if I can find a cheap pump.

Dazza

That will be the RS liberty water to air intercooler, the WRX has a top mounted air to air intercooler. I own an RS liberty, the WAIC is okay, but nothing flash. There are some upgrades that can be done, but overall they do limit power to about 190kw at all four wheels.

Layto....

Seen a few cheap pumps around the place from time to time just I've never been quite there in time. Saw a Davies Craig a while ago for $60 but missed by that much. One will turn up and the pump price will be the determining factor in how cheap I can build it. If I can get a suitable pump for under $100 then sub $300 is possible I think.

Interesting after looking at a couple of sites provided above most wate rot air units seem to run the water inside the tubes and the air over the fins which is opposite to air to air and opposite therefore to the way I was going. Have seen articles however on simple ones being done with just replacing the airflow in the traditional path with water.

discovering this was why I didnt get a cheap ebay core and add a water jacket to it. I wasn't convinced it was going to be the most effective system for the effort it would take to set upfester2au wrote: Interesting after looking at a couple of sites provided above most wate rot air units seem to run the water inside the tubes and the air over the fins which is opposite to air to air and opposite therefore to the way I was going. Have seen articles however on simple ones being done with just replacing the airflow in the traditional path with water.

the laminova's and others see the air intake charge pass over a very large surface area in a very short distance to remove heat quickly with least resistance from having to pass through long tubes.

another thing that looks good about the laminova's is that they dont look like they cause airflow to make big changes in direction to pass through the cores

Who is online

Users browsing this forum: No registered users and 1 guest