while looking around the net i notice they still dnt have a full radius around the side of them.

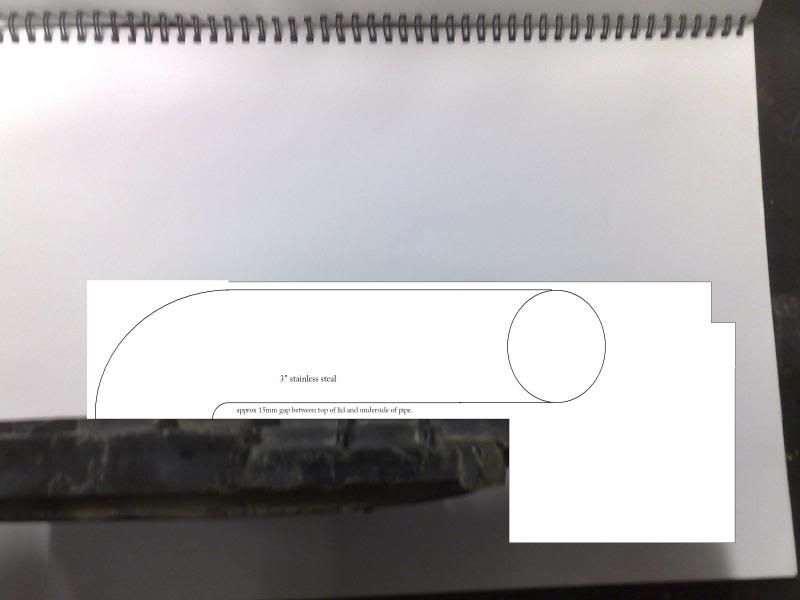

what i have thought of doing is removing what plastic mould that is currantly there and using a 3" stainless doughnut (to give a tight full bend) and go from there.

the inside diameter of a 3" doughnut is 30mm, so there would be a gap of 15mm between the lid and the underside of the stainless.

i dnt think its possible to get it any lower, only other way i can think of is doing a lobsterback which wont flow as well.

did some quik measurments and it looks like it will fit under the bonnet.

Any thoughts or ideas welcome. Im no master on the subject.

i here are some pics to better explain it.

STANDARD 4.2 AIRBOX LID

WHERE YOU WOULD MOUNT TO INSIDE THE LID, USING SILICONE AND SMALL NUTS AND BOLTS OR RIVITS. OF COURSE IT WOULD NOT STICK ANY FURTHER IN THAN THE BLACK PLASTIC DOES.

BASIC IDEA