Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

best way to make a tray

Moderators: toaddog, TWISTY, V8Patrol, Moderators

best way to make a tray

ok i need help...i want to build a tray...i was considering on using RHS 3mm thick steel to build the frame of the tray...however i wouldn't mind getting everyone's hints on tubing best designs before i get started ...so post away!!

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

what sort of design do you have i mind ?

pics of what sort of finished product you are wil help any advice we can give.

if your not sure there are plenty of threads with custom trays as the feature item

pics of what sort of finished product you are wil help any advice we can give.

if your not sure there are plenty of threads with custom trays as the feature item

Keep it shiny side up!

Now doing general fab work and painting

trays, trailers, engine swaps on request, some tube work, silo section sliders, rust repairs, ute chops etc

Now doing general fab work and painting

trays, trailers, engine swaps on request, some tube work, silo section sliders, rust repairs, ute chops etc

as a sheetmetal worker i suggest u grab a pen, a piece of paper. and brainstorm. flick through 4wd magazines, incorporate and modify designs and come up with something unique. I find a 4wd magazine to be the best inspiration for projects.

work out the width you want the tray, the length, how much weight it is going to take. draw those constraints on a piece of paper (eg, 2200mm X 1600mm) and draw the tray inside that.

Use box section to sit on the chassis rails 2 lengths running down, and then build ribs that go horizontally across. from those ribs comes your shape and design, i might not make much sense, its easier to describe in person but all i can say is draw draw and draw. find out the weight of a length of say 50X50RHS and work out how much material you will need, and create a small database of a total weight for the tray, that way you can say ok, that doesnt need to be 5mm thick, i can work out the atomic weight of that flatbar, and maybe change it to 3mm thick, adding a 16mm gusset for extra support.

blah blah sorry.. lol

work out the width you want the tray, the length, how much weight it is going to take. draw those constraints on a piece of paper (eg, 2200mm X 1600mm) and draw the tray inside that.

Use box section to sit on the chassis rails 2 lengths running down, and then build ribs that go horizontally across. from those ribs comes your shape and design, i might not make much sense, its easier to describe in person but all i can say is draw draw and draw. find out the weight of a length of say 50X50RHS and work out how much material you will need, and create a small database of a total weight for the tray, that way you can say ok, that doesnt need to be 5mm thick, i can work out the atomic weight of that flatbar, and maybe change it to 3mm thick, adding a 16mm gusset for extra support.

blah blah sorry.. lol

FRLS4B wrote:as a sheetmetal worker i suggest u grab a pen, a piece of paper. and brainstorm. flick through 4wd magazines, incorporate and modify designs and come up with something unique. I find a 4wd magazine to be the best inspiration for projects.

work out the width you want the tray, the length, how much weight it is going to take. draw those constraints on a piece of paper (eg, 2200mm X 1600mm) and draw the tray inside that.

Use box section to sit on the chassis rails 2 lengths running down, and then build ribs that go horizontally across. from those ribs comes your shape and design, i might not make much sense, its easier to describe in person but all i can say is draw draw and draw. find out the weight of a length of say 50X50RHS and work out how much material you will need, and create a small database of a total weight for the tray, that way you can say ok, that doesnt need to be 5mm thick, i can work out the atomic weight of that flatbar, and maybe change it to 3mm thick, adding a 16mm gusset for extra support.

blah blah sorry.. lol

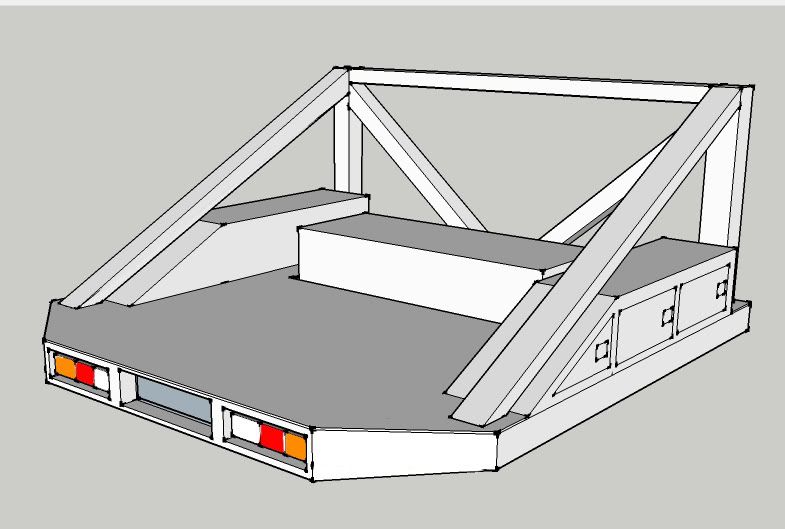

i was considering something like this

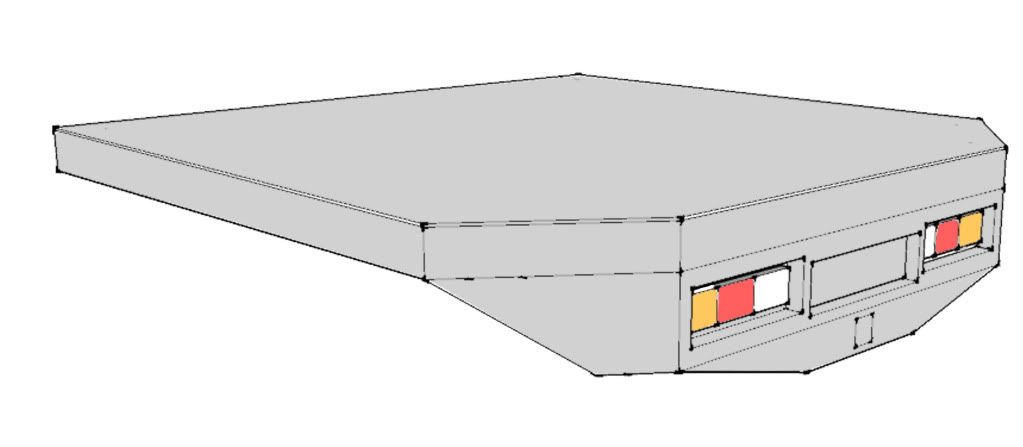

but with this back on it

i wont be carrying anything besides your basic recovery gear ...id like it to be 1600 w x 1780 L

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

just draw a very very brief sketch on paint for ya, here is a very basic design, just using 50X50 RHS

but yea just re touching what i said, build the 2 lines of box section that follows the chassis rails, then put ribs on TOP of them, not weld them flush in and then sides to those ribs etc, sheet of chequerplate on top, so many designs, so many things you can do for strength, if you want more help just ask, ill be making my own comp tray soon

but yea just re touching what i said, build the 2 lines of box section that follows the chassis rails, then put ribs on TOP of them, not weld them flush in and then sides to those ribs etc, sheet of chequerplate on top, so many designs, so many things you can do for strength, if you want more help just ask, ill be making my own comp tray soon

that rear that you want looks very unfriendly for depature angles when you 4wd  ouch

ouch

yes the tube frames look quite tricked up, but have you got a pipe/tube/mandrel bender? answer is probably no, do u have $1000 to buy a decent one ? maybe, square ones look just as good, although i will admit i will be getting 3" tube for my rollbar work bent by a place called u-neek bending but my tray will be of box section and some tricky sheetmetal work

yes the tube frames look quite tricked up, but have you got a pipe/tube/mandrel bender? answer is probably no, do u have $1000 to buy a decent one ? maybe, square ones look just as good, although i will admit i will be getting 3" tube for my rollbar work bent by a place called u-neek bending but my tray will be of box section and some tricky sheetmetal work

as the other dude said about building the box section then ill figure out all my design after that...and no i dont have that kinda a money lol wishes butFRLS4B wrote:that rear that you want looks very unfriendly for depature angles when you 4wdouch

yes the tube frames look quite tricked up, but have you got a pipe/tube/mandrel bender? answer is probably no, do u have $1000 to buy a decent one ? maybe, square ones look just as good, although i will admit i will be getting 3" tube for my rollbar work bent by a place called u-neek bending but my tray will be of box section and some tricky sheetmetal work

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

hey mate here is the link to my build...

did all the box section myself and checkerplate.. got Millweld to do the round bar work.

http://www.outerlimits4x4.com/ftopic165 ... light=tray

used 75x50x3 around the outside... 50x50x3 around the lights at the bak

30x30x3 (i think) for under the checkerplate, should say in the thread.

hope it helps

did all the box section myself and checkerplate.. got Millweld to do the round bar work.

http://www.outerlimits4x4.com/ftopic165 ... light=tray

used 75x50x3 around the outside... 50x50x3 around the lights at the bak

30x30x3 (i think) for under the checkerplate, should say in the thread.

hope it helps

i dont mind it however i want to make something different...anyways i think id continually break those lights how they are lol....the tool boxes on the design above i was considering on lifting the floor to allow more room for when i get flexi springs and 33s ....i want it to flex like no tomorrow lolLux_89 wrote:easy as fuk to make.. m8 welded it for me as thats what he does for a living, then we used 1 3/4 inch dom tube for rollbar.. soon to be chassi mount when time comes up.. i recon chassi mount for sureou plan on wheelin it...

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

Im not sure if your joking about hiluxes having no flex, because when i installed my 3" EFS lift i had HUGE flex, and thats only springs, no drop shackles, extended shackles, no droped arms disconnectable rods etc so please tell me you were joking?Lux_89 wrote:mate reality check ya got a hilux hahaha. no flex haha, yeh i thought the same too ay but mine gets driven hard offroad, n i havnt smashed one set yet...

i think if we fell over like that we would leak a little fluid too lol...or the driver more like it when it landed like that.... a couple of times iv thought i may need a new set of boxers lolLux_89 wrote:sometimes ya get lucky n all the oils come out automatically for ya.

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

Would be interested to see pics of your idea of HUGE flex? In reality compared to other setups the rear of a Lux with leafs will never flex anything spectacular imo.FRLS4B wrote:Im not sure if your joking about hiluxes having no flex, because when i installed my 3" EFS lift i had HUGE flex, and thats only springs, no drop shackles, extended shackles, no droped arms disconnectable rods etc so please tell me you were joking?Lux_89 wrote:mate reality check ya got a hilux hahaha. no flex haha, yeh i thought the same too ay but mine gets driven hard offroad, n i havnt smashed one set yet...

Toy: 98 TJ with some mods and some bling

Tourer and daily: 120 Prado with some mods

Tourer and daily: 120 Prado with some mods

yep id also like to see the pics of the huge efs leaf flex....its like a unicorn....my spring setup is far from efs status...n evven it isnt a huge flexing offtap rear end. Ill find a pic of it later.

Ur tray design looks good, altho id def make the rollbar out of round tube or pipe...theres a guy i see most days with a rhs rollbar setup, imo it looks wrrong and will never look as good as a round bar...

Ur tray design looks good, altho id def make the rollbar out of round tube or pipe...theres a guy i see most days with a rhs rollbar setup, imo it looks wrrong and will never look as good as a round bar...

Boondall backyard performance...SHANTYTECH 4034...

BMX bike - 20" maxxis stickies, 4130 tube frame, reduction gears.

BMX bike - 20" maxxis stickies, 4130 tube frame, reduction gears.

ill be getting the roll bar done professionally ...i just couldn't make a tube one using google sketch upRory wrote:yep id also like to see the pics of the huge efs leaf flex....its like a unicorn....my spring setup is far from efs status...n evven it isnt a huge flexing offtap rear end. Ill find a pic of it later.

Ur tray design looks good, altho id def make the rollbar out of round tube or pipe...theres a guy i see most days with a rhs rollbar setup, imo it looks wrrong and will never look as good as a round bar...

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

well i decided that i could make the base myself easy enough but i dont want to hold my life in my own hands ...id feel safer if someone that knows what they are doing makes the roll bar... a guy i know made his own but he originally worked for Brown Davis ...he uses 3mm thick pipe and also uses it as his air tankLux_89 wrote:yeh. big tube aint always best either, so get experimental.. you can get standard black pipe right through to chromo. thats why mines small, but strong as.

Northside Fleet Services PTY. LTD.

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

243 Dundas Street Preston, Victora

(03)94840432

(For all your Gas and Mechanical needs)

FRLS4B wrote:Im not sure if your joking about hiluxes having no flex, because when i installed my 3" EFS lift i had HUGE flex, and thats only springs, no drop shackles, extended shackles, no droped arms disconnectable rods etc so please tell me you were joking?Lux_89 wrote:mate reality check ya got a hilux hahaha. no flex haha, yeh i thought the same too ay but mine gets driven hard offroad, n i havnt smashed one set yet...

Ln65 single cab

hmm perhaps HUGE compared to what i used to own (mitsubishi triton), but from what i gathered from the other guys statement he said that hiluxes flexing were a joke, didnt say 'a stock hilux flexing is a joke', anyway here are some pics of just after i fitted the 3" EFS lift, springs and shocks, no more modifications as of yet no leaf resetting or adding dropped arms or longer shocks..

Who is online

Users browsing this forum: No registered users and 1 guest