Moderators: toaddog, TWISTY, V8Patrol, Moderators

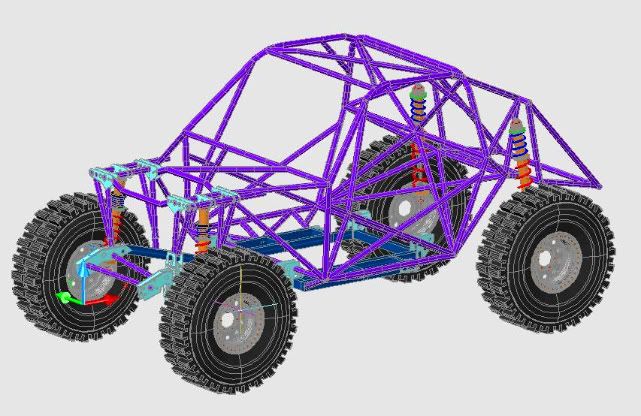

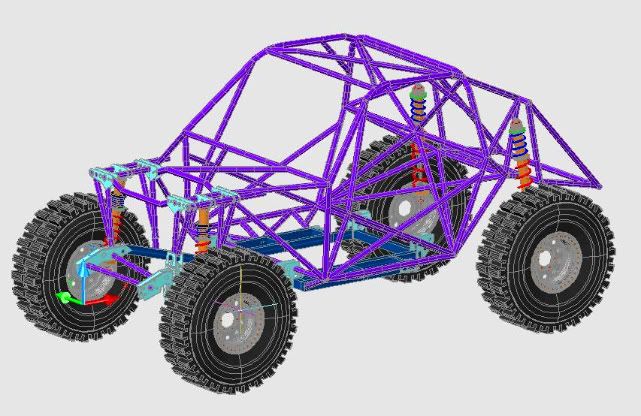

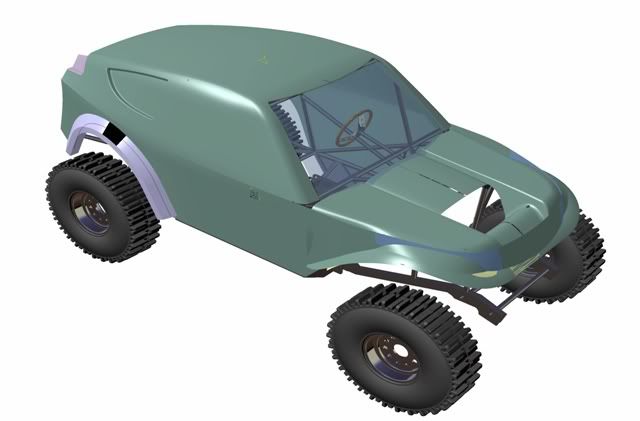

Well, as I said: after a lot of years I learned to learn from others, mainly because I spent a lot of money doing mistakes. This structure is not my invention, but it has been done previously by the VW Race Touareg for the Dakar (btw, we are the first romanians ever registered to compete in the Dakar, cars category;-). The reason is simple and effective: when you build a car from scratch, the most important thing is to be sure that the base, or the arms fits, are square and right. By experience I know (and seems that VW knows also...) that to get a structure right is much easier and with a far better result if you start with a rectangular tube instead of round. All the rest of the structure is with round tube, a special alloy ordered by us to a big factory here in Romania. This material exceed with 90% the FIA regulations for the structures, saving in the same time 20% of the weight.bad_religion_au wrote:awesome, i'll be watching this build.

any reason you start with RHS chassis instead of making it all round tube?

;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

Makes sense to me now! good to see a good idea that's outside what we see all the time! thanks for the reply.Gabriel wrote:Well, as I said:bad_religion_au wrote:awesome, i'll be watching this build.

any reason you start with RHS chassis instead of making it all round tube?

thanks for looking,

Gabi Nicolae

I don't hate her either.Gabriel wrote:;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

RN wrote:I don't hate her either.Gabriel wrote:;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

http://www.examiner.com/x-12090-Pageant ... Constantin

MightyMouse wrote:VERY, VERY impressive.

It something that most of us dream about but few have the knowledge / facilities / money and sheer patience required to build things to this standard.

I'm looking forward to seeing more of the build.

Hello,MightyMouse wrote:Welding looks like TIG not MIG to my very inexperienced eye.....

I would have expected TIG with the mention of alloy steel earlier on.

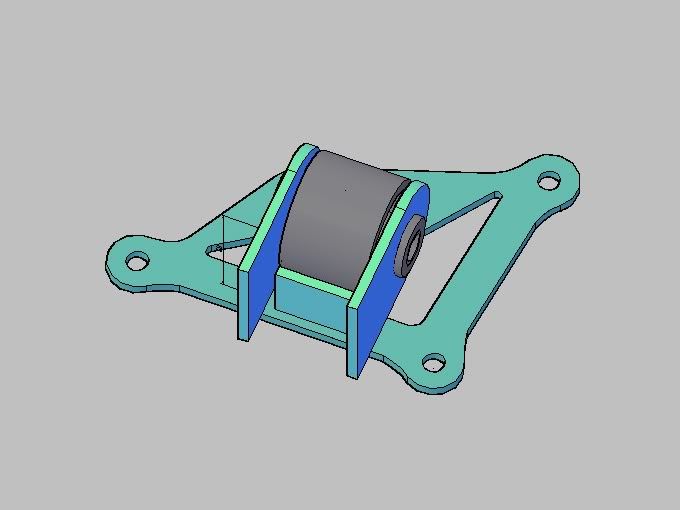

Yes, we used a program (I can't tell you the program name because then I would have to shoot you ;-))) in order to simulate the loads and more important the effort dissipation in case of roll over (I know, its not good, but you can expect tis kind of accident). The first results was great, and because of that we mounted some more triangulated bars then in the first drawings. Anyway... We will see if the theory matches the real life in april, when the cars must race.coxy321 wrote:Camel Toe anyone?

Have you guys done simulated tests on the stress/load on that support junction? It'd be interesting to see what sort of stress is there with seven points coming to one.

Super neat weld job by the way!

More pics

Users browsing this forum: No registered users and 2 guests