I'm finally getting my drawers organised for a few trips coming up this year. I have replaced all of the dodgy Sylon rollers with some 6300's, and fixed up 1-2 cracked welds too.

The drawers are not "branded", however they do appear to be manfactured as opposed to a backyard job. All folded and seam welded, all gal steel. The top was 12mm marine ply with marine carpet, much the same as most other drawers you see on the market.

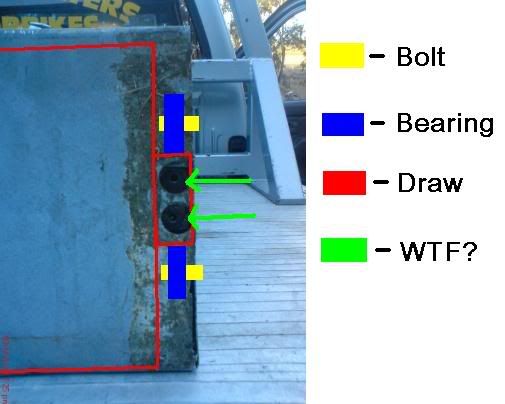

At present, there is no drawer retaining system in place, ie. if you were to open a drawer with the car pointing up hill, they would just fly out completely. While i have thought of a few different ways of retaining the drawers, i thought that this might have something to do with it (items labelled "WTF?")

There is a 3mm plate on the butt of the box section (which the rollers run on), which also has two threaded holes in it. The actual drawer chassis also has two holes cut in it to allow access to these threaded holes.

Does anybody know what they're for?

Cheers!