Ok well shopping list up first (typical prices and what we paid for them to come)

Shopping List

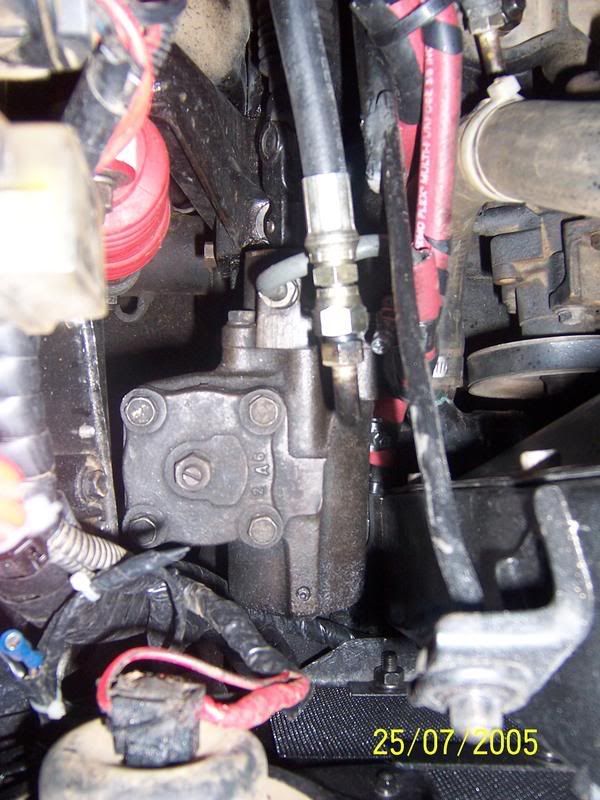

60# powersteering box

75# Pitman arm ( not necessary but gives more clearance for the springs)

75# steering arms

75# Draglink

75# Tie-rod

60# 2h powersteering pump (if you have a B or F motor get the pump for that motor)

60# Fan (for clearance not needed with B or F motors i think)

60# Power Steering Belt (different for B and F motors)

60# Harmonic Balancer Pulleys (Again not sure with B or F motors)

55# Steering Column

75# Steering shaft with Uni's

80# Cushion Joint

40# Cooling lines (We used a 60# and modded it to fit)

4 x Crush tubes

4 x High Tensile Bolts

2m of hose and clamps (make sure its oil and pressure rated)

75# Tie-rod end kit (only if needed)

Some 6mm plate for inside of chassis brace and for shock tower

Steering Dampner to suit MK/MQ