See. Now your thinkingTiny wrote:agree, box section chassis, 4 bends in total on 2 bits of tube is the only bit any mug with a welder and grinder cant do thentoughnut wrote:Just trying to come up with an easy formula. If you make it a basic ladder frame with the roll over protection it sets an easy platform for people to work from even if they haven't built stuff like this before.Screwy_ScrewBall wrote:so the main rails have to be box section with turb for rollover protection? could we not run tube complete full frame?

disagree that you need steel roof etc, roof neds to be covered but mech is fine, same with the sides, bit of plastic would be fine.

might get the old bikes into the workshop in the next few weeks and start on a frame

thinking some small hatch type CVs for the drive off a sprocket mounted with two bearings, one either side with brass bushing to space it right ??? i think keep is simple stooopid is the right formula

with the suspension, I am lost as to come up with a double boxed arm or similar to keep the wheel strightt or if a fixed wheel with the chassis mount hinged would be better....probably simpler

Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

lil rock buggy class specs on page 6

Moderators: toaddog, TWISTY, V8Patrol, Moderators

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

I wish you luck and hope that the class gets off the ground it could be fun...

Unfortunately it sounds way to complex for this monkey.. I understand that it is your brain child and you have firm idea of how it should be built and run ... as it stands I would not begin to attempt it ...

reasons being you would have to have access to some reasonably expensive fab equipment to even begin, you have a totally custom machine, most will find it difficult to justify paying a machinist XX$ per hour to mod a part.. they if it breaks .. you bend over again.. and your out for the weekend ... (not much chance of borrowing a totally custom one of part that an over excited 12 year old broke when they forgot to get of the accelerator when the rig got bound up)

If it supposed to be a fun class (learning for kids and spotters alike) make it easily accessible and reasonably affordable with mostly off the shelf parts for the drive line.. (the most likely parts to be broken by inexperienced drivers) ingenuity will follow as the class progress's ... and is seen as worthwhile...

I am just trying to give an amateur's opinion on this ..

Unfortunately it sounds way to complex for this monkey.. I understand that it is your brain child and you have firm idea of how it should be built and run ... as it stands I would not begin to attempt it ...

reasons being you would have to have access to some reasonably expensive fab equipment to even begin, you have a totally custom machine, most will find it difficult to justify paying a machinist XX$ per hour to mod a part.. they if it breaks .. you bend over again.. and your out for the weekend ... (not much chance of borrowing a totally custom one of part that an over excited 12 year old broke when they forgot to get of the accelerator when the rig got bound up)

If it supposed to be a fun class (learning for kids and spotters alike) make it easily accessible and reasonably affordable with mostly off the shelf parts for the drive line.. (the most likely parts to be broken by inexperienced drivers) ingenuity will follow as the class progress's ... and is seen as worthwhile...

I am just trying to give an amateur's opinion on this ..

" If governments are involved in the covering up the knowledge of aliens, Then they are doing a much better job of it than they do of everything else "

love_mud wrote:I wish you luck and hope that the class gets off the ground it could be fun...

Unfortunately it sounds way to complex for this monkey.. I understand that it is your brain child and you have firm idea of how it should be built and run ... as it stands I would not begin to attempt it ...

reasons being you would have to have access to some reasonably expensive fab equipment to even begin, you have a totally custom machine, most will find it difficult to justify paying a machinist XX$ per hour to mod a part.. they if it breaks .. you bend over again.. and your out for the weekend ... (not much chance of borrowing a totally custom one of part that an over excited 12 year old broke when they forgot to get of the accelerator when the rig got bound up)

If it supposed to be a fun class (learning for kids and spotters alike) make it easily accessible and reasonably affordable with mostly off the shelf parts for the drive line.. (the most likely parts to be broken by inexperienced drivers) ingenuity will follow as the class progress's ... and is seen as worthwhile...

I am just trying to give an amateur's opinion on this ..

The way I want mine to be set up Driveline breakages will be of the past

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

Thats if YOU are driving it .. I am pretty certain the guys from ABT didnt think that they would be shearing 4 out of 5 12mm grade 10.5 bols and twisting the crap out of a steering arm either ..MADZUKI wrote: The way I want mine to be set up Driveline breakages will be of the past

I am talking about with an inexperinced kid behind the wheel .. but I think I see what this class is really more about.

" If governments are involved in the covering up the knowledge of aliens, Then they are doing a much better job of it than they do of everything else "

love_mud wrote:Thats if YOU are driving it .. I am pretty certain the guys from ABT didnt think that they would be shearing 4 out of 5 12mm grade 10.5 bols and twisting the crap out of a steering arm either ..MADZUKI wrote: The way I want mine to be set up Driveline breakages will be of the past

I am talking about with an inexperinced kid behind the wheel .. but I think I see what this class is really more about.

No. It will not be exxy to make stronger than it ever needs to be. We arent running a built 350 and 40" rubber

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

I'm not getting anything made for me and I don't have a lathe or machining press or any of that gear. What I do have is a drop saw, angle grinder, an ark welder, a small mig welder and I have access to a tube bender, but as I said, the only thing most would have to get done is to get the "A" and "B" pillar bent up and the rest can be straight bar. I'm going to get the diff centres out of a zuk and pinch the crown and pinion. I'll bolt the crown to a flat flange and mount the pinion in a couple of bearings with bronze bushes to shim it up. As for axels I'm thinking of finding something suitable at a wreckers. Or get some short drive shafts with U/J's on each end for the axels. As for suspension I'm going to try an idea that I have about using a pair of motocross forks on each corner. Wheel will be a set of what ever I can source at the time but I want to run ATV wheels and tires. I have a couple of options for engines. Not sure which way I want to go yet. steering will be easy to set up and I can get disc brakes of any motorbike. See. Not so difficult if you do a little research into what parts you can source from other vehicles etc. I'm sure that we'll see a lot of neat ideas that are really easy to do and cheap as welllove_mud wrote:Thats if YOU are driving it .. I am pretty certain the guys from ABT didnt think that they would be shearing 4 out of 5 12mm grade 10.5 bols and twisting the crap out of a steering arm either ..MADZUKI wrote: The way I want mine to be set up Driveline breakages will be of the past

I am talking about with an inexperinced kid behind the wheel .. but I think I see what this class is really more about.

This buggy will at the most cost me $3500 if that.

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

Including the trailer

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

If you're running driveline cv parts made up for say, 80kw fwd cars with triple the capacity and about4 times the weight, but running a 30kw trailbike engine I dont think the risk of breakages is that high.

It's not like we're running heavy tyres with trailbike and ATV wheels is it.

If I look at building one of these later (cant do it now but after I've got the house then I'd be interested) then I'd be using front and rear half shafts out of some very common small car (eg KE laser would be good).

The axle would be thick tube at either end (might even go solid if weights not a problem) to a welded on plate at one end (the other end would need to be able to pass through the axle bearing to replace the sprocket) that the car CV would bolt to. None of these slide in/circlip type arrangements.

Kind of like a hybrid between an IFS Hilux/Vitara diff/axle with a go kart.

Drive would be by chain to a side offset sprocket for better centre clearance.

I might bolt those plates on at both ends first during the testing stages, since I may end up changing the source CV's used if I start breaking them.

Busted CV = $50 at the wreckers max, and probably no more than about 6 minutes to repair (replace whole shaft). After all it's only gonna be about 8 bolts to undo and do...... 5 minutes will be finding where you dropped that nut in the dirt

Similar to go kart on the disc fitment too. Seperate circuits with a kind of two in one pedal for individual control. With the kind of park brake you see on golf buggies on each too for some dragging turn capability.

A car steering box and rods would probably be used for strength reasons, but I'd be sticking with a vitara style design for the front wishbones, although this would be tube made rather than using massive car castings..

It's an easier steering design too, and could easily be run at both ends....although except for showing off I cant see why you need 4ws on an 8 foot long buggy..

The rear I'd probably look at a swingarm type arrangement, and then CV's as well to allow greater suspension movement at the back end than just CV's would allow. This would also allow for a much ligher rear frame (which is exactly how and why it's done on motorcycles).

So vertical motion controlled by the swing arm, and left to right flex by the CV's.

May end up not working (two different methods of flex might make the balance hard to get) but I'd want to give it a go. If it didnt work, you could always lock the swingarm in place - maybe have it adjustable height for between stages with locating pins, but fixed during the stage.

If the balance in the spring rates for the main swingarm and the individual wheel springs works, I might consider it for the front too.

Pity there's no adjustable height mid stage, cos the swingarms and airbag combo would rock.

The chain routing mihgt be interesting - the way I see the best simple power coupling arrangement would be using 6 sprockets (erk) I might consider running 8 for better chain routing.

Hmmm 8 sprockets....... anyone thinking of the possible gearing options?

Im also tossing up the idea of some form of belt drive from my reverse/transfer box instead of chain though. Guaranteeing tensioning the drive belt might be too hard in the potentially wet or dusty conditions though, and belt drives are renowned for being fragile, so they would need to be protected very well (probably run fully enclosed would be the only way).

Reduction gear ratios would then be more dependant on the transfer case sprockets, as opposed to the kind of portal style double reduction.

Not so many choices with gearing when dealing with pulleys as there is with sprockets.

It's not like we're running heavy tyres with trailbike and ATV wheels is it.

If I look at building one of these later (cant do it now but after I've got the house then I'd be interested) then I'd be using front and rear half shafts out of some very common small car (eg KE laser would be good).

The axle would be thick tube at either end (might even go solid if weights not a problem) to a welded on plate at one end (the other end would need to be able to pass through the axle bearing to replace the sprocket) that the car CV would bolt to. None of these slide in/circlip type arrangements.

Kind of like a hybrid between an IFS Hilux/Vitara diff/axle with a go kart.

Drive would be by chain to a side offset sprocket for better centre clearance.

I might bolt those plates on at both ends first during the testing stages, since I may end up changing the source CV's used if I start breaking them.

Busted CV = $50 at the wreckers max, and probably no more than about 6 minutes to repair (replace whole shaft). After all it's only gonna be about 8 bolts to undo and do...... 5 minutes will be finding where you dropped that nut in the dirt

Similar to go kart on the disc fitment too. Seperate circuits with a kind of two in one pedal for individual control. With the kind of park brake you see on golf buggies on each too for some dragging turn capability.

A car steering box and rods would probably be used for strength reasons, but I'd be sticking with a vitara style design for the front wishbones, although this would be tube made rather than using massive car castings..

It's an easier steering design too, and could easily be run at both ends....although except for showing off I cant see why you need 4ws on an 8 foot long buggy..

The rear I'd probably look at a swingarm type arrangement, and then CV's as well to allow greater suspension movement at the back end than just CV's would allow. This would also allow for a much ligher rear frame (which is exactly how and why it's done on motorcycles).

So vertical motion controlled by the swing arm, and left to right flex by the CV's.

May end up not working (two different methods of flex might make the balance hard to get) but I'd want to give it a go. If it didnt work, you could always lock the swingarm in place - maybe have it adjustable height for between stages with locating pins, but fixed during the stage.

If the balance in the spring rates for the main swingarm and the individual wheel springs works, I might consider it for the front too.

Pity there's no adjustable height mid stage, cos the swingarms and airbag combo would rock.

The chain routing mihgt be interesting - the way I see the best simple power coupling arrangement would be using 6 sprockets (erk) I might consider running 8 for better chain routing.

Hmmm 8 sprockets....... anyone thinking of the possible gearing options?

Im also tossing up the idea of some form of belt drive from my reverse/transfer box instead of chain though. Guaranteeing tensioning the drive belt might be too hard in the potentially wet or dusty conditions though, and belt drives are renowned for being fragile, so they would need to be protected very well (probably run fully enclosed would be the only way).

Reduction gear ratios would then be more dependant on the transfer case sprockets, as opposed to the kind of portal style double reduction.

Not so many choices with gearing when dealing with pulleys as there is with sprockets.

slosh wrote:Ummm, what I have described will fit into toughnuts rules... 2 x 125cc motors, driver will sit very low between engines so there is a lot of side protection.MADZUKI wrote:Doesnt matter, this class wont be catering for itslosh wrote:You have got to be kidding! I have never seen anything like I have described.toughnut wrote:There are already classes that cater for thisslosh wrote: An idea I have is using 2 complete trail bikes (pref old motorcrossers) building a frame to connect them together side by side with seat in between.

What is it going to be then? Innovation or just build something that looks like a rhino buggy?

So long as you build the appropriate cab area protection the rest of it all sounds ok so far, and quite interesting.

As to keeping the two engines in synch, it'll be interesting if one is in better condition and more responsive than the other.

Now if you took the rear idea - two seperate swingarms, chain driven, and applied it to the front, then came up with a steering method, things will get really interesting.....

Pivoting chassis mounts for the front swingarms sounds good to me (kind of like earthmoving equipment), but may be a little bit too much for scrutineering in the long term. Be an interesting challenge to overcome the chain drive too...

I have another idea which I cant really explain easily.... it would need bowed singlesided front swingarms to work, kind of in a a hybrid of a standard mcpherson front strut arrangement with knuckle and the steering arrangement of a GTS1000 Yamaha...

Any rules about extendable/contractable wheelbases on the fly, assuming you stay within the 2500mm at maximum? I have another interesting steering idea im pursuing........

Have you seen the front swing arms on some of the BMW's

Or what if the whole front and rear end of the frame articulated

So many ideas so little time and money

Or what if the whole front and rear end of the frame articulated

So many ideas so little time and money

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

I cant see a single sided swing arm, or a normal one for that holding up to the side loads that would be needed. The chance of pulling a mount off the chassis or cracking the alloy would be huge

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

I understand keeping it simple in setting up a box section chassis.Tiny wrote:agree, box section chassis, 4 bends in total on 2 bits of tube is the only bit any mug with a welder and grinder cant do thentoughnut wrote:Just trying to come up with an easy formula. If you make it a basic ladder frame with the roll over protection it sets an easy platform for people to work from even if they haven't built stuff like this before.Screwy_ScrewBall wrote:so the main rails have to be box section with turb for rollover protection? could we not run tube complete full frame?

I also understand all the measurement and weight restrictions being in place.

BUT

IF i was to CHOOSE on my own personal choise to run all tube rather than box on the chassis WOULD THIS BE ALOUD?

or will i be forced at box section for the chassis under class rules?

TUFF TRUCK TEAM OPPOSITE LOCK Proudly Sponsored By:

Opposite Lock Narellan, Lightforce Australia, Offroad Systems, Judd Panels, Townsend Signs, RDG Engineering, Central Safety Workwear

Opposite Lock Narellan, Lightforce Australia, Offroad Systems, Judd Panels, Townsend Signs, RDG Engineering, Central Safety Workwear

in my opinion it should be minium weighttoughnut wrote: Max weight 500kg

Steering must be mechanical 4ws allowed must use steering wheel

Suspension IFS/IFR, must not be adjustable during a stage.Each wheel must have a minimum of 8inches of travel independant to all others..

1.yous havent built one yet so you might really struggle to get it under 500kg

2.being heavier is a dis advantage so let them build it as heavy as they want u

3.and some one who has got lots of money will build a carbon fibre cromoly thing that would give them a clear advantage

4ws ?? no offence but do u think these thing are gunna be capable enuff to even need it

id make the rule front or rear steer only

why is there a minium wheel travel?

sounds dumb?

Team UNDERDOG #233

WERock Australia thanks to

[url]http://www.longfieldsuperaxles.com[/url]

[url]http://www.rockbuggysupply.com[/url]

WERock Australia thanks to

[url]http://www.longfieldsuperaxles.com[/url]

[url]http://www.rockbuggysupply.com[/url]

It wasn't towards one thing in particular, more so just to fit more in with your ideas of a "begginer class" things readily avaialble, so that it's simpler and easier to do. Look at what gets other motorsport classes off the ground or feeds them. It's the abilility to use something that has already been built for something else which can easily be adapted across or bought prebuilt at a reasonable cost. You'll quickly find you only have a few interested and you may actually be lucky enough to have 2 or 3 of these people living in roughly the same area where you can actually test yours against theirs.toughnut wrote:I meant zuk base buggy that r0ck_m0nkey seems to be pushing more towards.

Due to the rules you have outlined, wether it be dimensions, suspension set ups etc. you have already made things like the buggy designs by The Edge Products, Honda Odysseys and a host of other already similiar things that people are likely to already own or have, inelligible to be used. Opening the "rules" up a bit to allow these already available products would actually be beneficial.

I'd scrap any ruling on suspension type, if people want IFS/IRS let them, If they want IFS, swingaxle solid rear let them, if they want no suspension let them. Open the overall width up a bit to 1600mm atleast. This alone would open up to allow already existing small buggy type vehicles.

Do you really need a Fire Exinguisher? No other small vehicle (Karting, ATV, Motorbike etc.) class requires one, so why this one? Equipped marshells would be just as easy, these things would only hold a few litres maximum of fuel and other fluids, so your not up for any major fire.

Alot of the other "safety devices" (kill switches, firewall etc.) you have listed are again things not required from similiar sized motorsports, so again, why this one? Chain guard would be the only major necessary thing. Wrist restraints as mentioned would be more important then window mesh. If you have ever rolled something of this size, you would realise you have a tendancy to try and grab the frame to support yourself whilst halfway over, fingers end up on outside of frame and if your lucky they don't get squashed.

If God did not intend for us to eat animals, then why did he make them out of meat?

First you have no minimum weight? Last time this no minimum weight was disccused we found a built offroad buggy on line that weighed 60KG complete(Ive searched and cant find it this time). So Im going to enter a team with this buggy and NAM Driving with Tiny Spotting. So you have a buggy that weighs 60KG a driver that weighs 50KG and A spotter that can pick them up and carry them around any course you build.

Second who is going to run this event and where will you get insurance that will cover these vehicles competing? And you cant run a competition with no insurance because everyone competing promises to not sue you. And no waiver will cover you for this either.

Good luck but i cant see this getting off the ground on the cheap.

Second who is going to run this event and where will you get insurance that will cover these vehicles competing? And you cant run a competition with no insurance because everyone competing promises to not sue you. And no waiver will cover you for this either.

Good luck but i cant see this getting off the ground on the cheap.

Give it time Tony, we arent expecting this to be a full blown class overnight. No doubt it will be a few years, but its a start for those who want to build a buggy in the mean time while the rest is getting set up.

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

The only big mistake can see you are making at the moment is setting no minimum weight. Your going to end up with someone competing in a cardboard box. Get rid of the maximum weight as the heavier they are the more useless they will be and add a minimum weight. I would think that 250-300KG would be a good point to set it at.

As soon as we have one built then we can set weight, or atleast a set of plans drawn up. With the chassis spec's there is not a whole lot left open to leave out to make lighter but I do agree about minimum weight.

What are insurance costs like for WeRock PA?

What are insurance costs like for WeRock PA?

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

Tony. We haven't even started on the actual competition side of things yet. It's still a concept. For everyone else. Stop being so negative about the concept. If you don't like it, make your own. I don't need to explain myself a thousand times why we've made a particular rule. Just know that we've made it for a reason, like the mimimum suspension travel. I have already identified a loop hole that people adament about using a solid axle will take. ie make the IRS almost rigid with just a small amount of momvement and then just build around that as if it is a solid axle. Like beastmavster was leaning towards with his rear swing arm setup. Guys the parts that you can find to build buggy that fits in these rules are quite easy and if we were to change the rules to suit existing buggies that are available then why have fledgling concept in the first place. r0ck_m0nkey, if you want to be lazy and go and buy something that is already built then stay sitting on your ass and wait until one of these become available. Otherwise get off you ass and use your imagination. I haven't set a minimum weigth because with design specs that we have set for chassis and roll over then it basically sets it's own minimum weight. OH and as for a spotter picking it up. We've already ruled this out so the spotter can only guide or stack but not touch the buggy

http://www.outerlimits4x4.com/viewtopic ... 6&t=231346j-top paj wrote:gayer than jizz on a beard

How many peeps from the Brizzy area are keen & ready to have a go at this class. Even if the comps or class doesn't get offically off the ground for some time I can't see why we can't run our own playday comp in the meantime. Some of the new tracks to be built shortly could be designed for this class.

Road Ranger

damb, me and nam were going to win every comp and take home al the loottoughnut wrote:t. OH and as for a spotter picking it up. We've already ruled this out so the spotter can only guide or stack but not touch the buggy

the benifit of the ifs irs set ups is you can solit mount the "diff" arrangment to stop any chain tensioning issues and properly gaurd the chain, this is the only real dangerous part IMO

Screwy, I dont think anyone would stop you making the chassis out of tube, the only reason why it is not speced as such is the make is easy for anyone with a grinder and a welder to make a large proportion of the frame themselved, only bit needed to bend being the two hoops

I am wondereing is we stop the reverse altogether, spotter can pull the thing back, again simpler, minimises gearing to sprockets

Also I thing no car type diff, must be direct chain drive or belt drive

steering should be a small car steeering box

If the above post did not offend you in any way please PM me so I can try harder!!

Tiny wrote:

Also I thing no car type diff, must be direct chain drive or belt drive

Car type diff IMO is stronger and cheaper by far not to mention safer. Have you priced up 4M of 520 chain lately??

[quote="dazza30875"]whats "FAIL" mean[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

[quote="fool_injected"]

Sometimes your funny Canada :D[/quote]

Car type diff might be cheaper..... but then you need to buy or make driveshafts. Driveshafts are heavy, and would sap a fair bit of power. Remember this will be using 400cc engines so really you need a very light drive mechanism.

There are not that many sources for light independant suspensions type diffs, since most cars went front wheel drive. You'd basically be looking at things like Suzuki vitara diffs, or datsun IRS diffs.....

If that's in scope then I really thing you'd be better off allowing shaft driven motorcycle engines to begin with - stuff like cx500 maggots, GT550's, XV550 etc. And then use shaft drive throughout the bike.

Ditching the reverse idea would be much simpler, but theres no way the spotter could necessarily pull 400kg + driver backwards in all conditions.

Once again, using electric motors makes this so much easier..... less safety and cost issues about how the power is transferred to the axles and your reverse gear is a cinch. Perhaps use a motorcycle engine as a generator for your power, or just run a generator. Could be handy for those summer blackouts we get in QLD too

Due to cost and potential safety risks, I'm also seeing a good case for allowing full belt drive, rather than specifying that there must be chain drive in there somewhere. obviously you could just run a short chain drive to a kind of splitter box and run belts from there.

However, in the long run I'm betting chain still works out cheaper than belts.

I agree that the rules should be be set up in such a way that things like sidewinders and oddysey buggies should be able to compete in the same class, or at least as a subclass (like we used to see at bathurst).

If the idea is to have soem fun and test out new technology and it cant beat an oddysey, well you'd have to come up with some new ideas

However, I'd never agree that any form of stripped down car based chassis should be allowed.

There are not that many sources for light independant suspensions type diffs, since most cars went front wheel drive. You'd basically be looking at things like Suzuki vitara diffs, or datsun IRS diffs.....

If that's in scope then I really thing you'd be better off allowing shaft driven motorcycle engines to begin with - stuff like cx500 maggots, GT550's, XV550 etc. And then use shaft drive throughout the bike.

Ditching the reverse idea would be much simpler, but theres no way the spotter could necessarily pull 400kg + driver backwards in all conditions.

Once again, using electric motors makes this so much easier..... less safety and cost issues about how the power is transferred to the axles and your reverse gear is a cinch. Perhaps use a motorcycle engine as a generator for your power, or just run a generator. Could be handy for those summer blackouts we get in QLD too

Due to cost and potential safety risks, I'm also seeing a good case for allowing full belt drive, rather than specifying that there must be chain drive in there somewhere. obviously you could just run a short chain drive to a kind of splitter box and run belts from there.

However, in the long run I'm betting chain still works out cheaper than belts.

I agree that the rules should be be set up in such a way that things like sidewinders and oddysey buggies should be able to compete in the same class, or at least as a subclass (like we used to see at bathurst).

If the idea is to have soem fun and test out new technology and it cant beat an oddysey, well you'd have to come up with some new ideas

However, I'd never agree that any form of stripped down car based chassis should be allowed.

I think you're missing my point. If you have rules that allow currently available, readily, cheaply available vehicles, then you have a a bigger starting point. Instead of waiting years for enough people to build these things to a certain spec, that actually all live in a close enough vicinity, you have an exisitng base already to start with. As competition develops, these already available machines in their current form may become uncompetitive against the few that have been built from scratch, so they are then modified to keep up, or another built to use.toughnut wrote:r0ck_m0nkey, if you want to be lazy and go and buy something that is already built then stay sitting on your ass and wait until one of these become available.

Starting with something available will develop quicker then waiting for who knows how long enough people to build. Otherwise it would be nothing more then 2 or 3 mates trying to outdo each other whilst others sit elsewhere driving by themselves with a few mates taking turns. Fun yes, but hardly a competition.

If God did not intend for us to eat animals, then why did he make them out of meat?

Except the same could be applied to events like werock/tough truck etc?r0ck_m0nkey wrote: Starting with something avaialble will develop quicker then waiting for enough people to build.

Why should we bother to build buggies, when a trials bike could complete the course easily in far less time, and be way cheaper to buy and maintain?

I agree with you up to a point - I think that allowing existing motorbike based buggies to compete would be good.

But, classes need rules, they dont want cars competing. Enough said on this already. If you dont think that's fair, let NAM compete at werock on his trials bike. Or better yet someone with more trials experience who has the ability to climb up a 4 foot high vertical ledge with their eyes closed.

With no foot down penalties in the rules, he'll hammer everyone by a mile and we'll throw away all the buggies and tough trucks built.

Classes exist so like minded people can play. Obviously you're not like minded and dont want to play in this class. That's fine, accept the fact that there are others who really like the path it's heading as it is now.

Sure I can see some ways I'd like it to go which are a little different, but they're testing an idea out.

A couple of years ago there were no buggy classes here in Oz. While most of the technology had already been proven in car based vehicles, they still needed to adapt rules. A couple of pioneers built some buggies outside of having somewhere to compete and showed the potential. Then new classes followed.

Give these a chance to make a couple and see whats a good rule and whats a bad rule. Then if you're interested you can join in.

It would be cool to see this class up and running, but i think there are to many rules on how to build it already, I think u could get ride of the max weight, the box frame, the irs ifs rule and the minimum supension travel rule, let people think for them selves and build what ever is cheap for them... just a thought???

reverse is the easy part of the whole buggy, sand buggys just use a small starter motor that pushes onto the chain when u want to reverse.

U might want to set a fuel octain rating rule though other wise u are going to get some faily wild 400cc buggys rocking up.

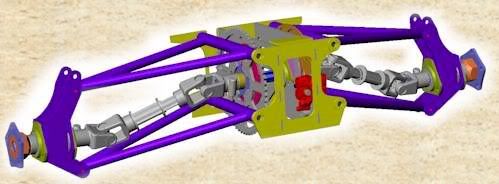

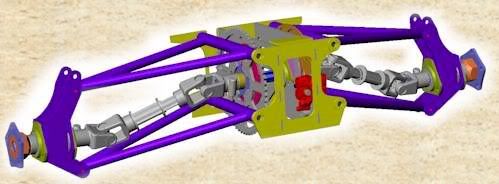

some supension ideas from the Edge Products over here in WA

first kit is $2300

reverse is the easy part of the whole buggy, sand buggys just use a small starter motor that pushes onto the chain when u want to reverse.

U might want to set a fuel octain rating rule though other wise u are going to get some faily wild 400cc buggys rocking up.

some supension ideas from the Edge Products over here in WA

first kit is $2300

Shane

Who is online

Users browsing this forum: No registered users and 2 guests