i'm currently working on a 2002 turbo deisel twin cab for a couple of friends who had some 80 diffs sitting around. now for starters this is not being built for stupid amounts of flex etc. its being built to be a little more capable and to run max 35 inch tyres. we pretty much want this vehicle to be a good performer off road and drive very well on the road.

the front will be done soon, but for now the rear was my concern as we wanted to maintain the larger fuel tank in its current spot. the rear is being flipped and coil mounts etc modded to suit. the rear will be five link, while the front will be three using original arms.

the vehicle..............

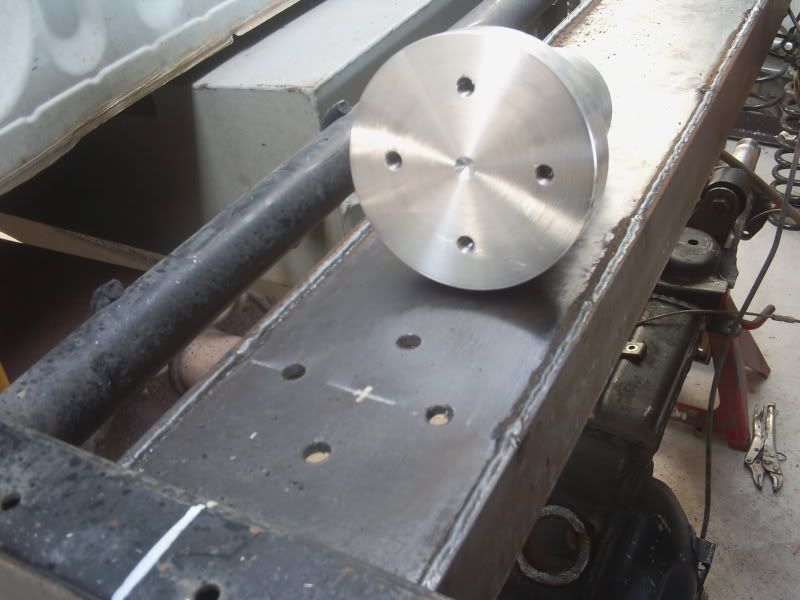

the 80 rear. it will be flipped including being modded to rotate the centre 180°, this also involves cutting and rotating the pumkin 'hat' to suit as well as some new notches for the ring gear.

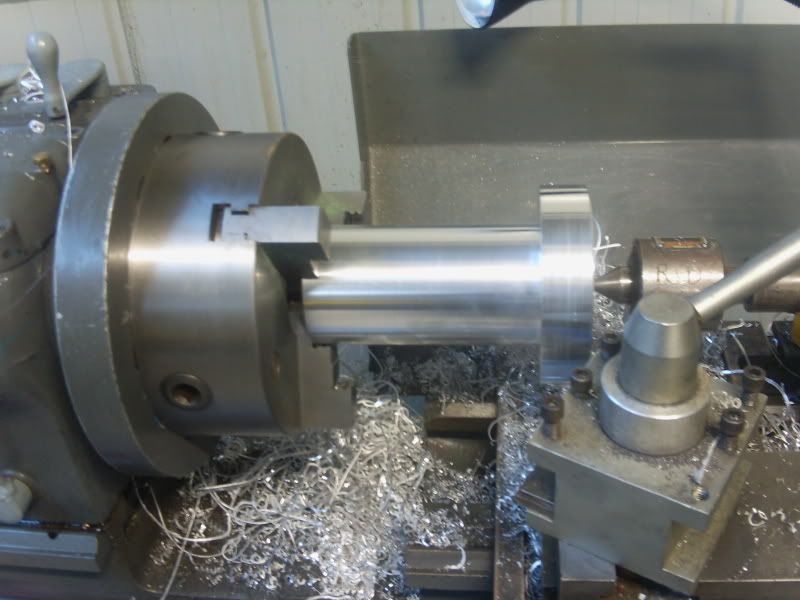

some fun with a plasma.....

some cleaning up afterwards.....

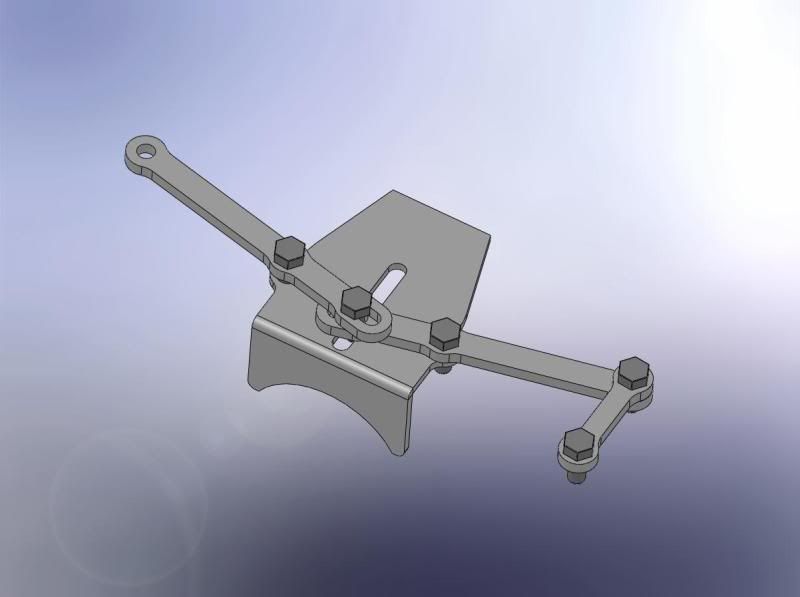

the lower coil mounts are being placed just inboard of the chassis using jk wrangler front coils. had to be modded to suit the bracing that was originaly on the bottom of the diff and is now on top.

the new pass side mount was slightly cut into the bracing so it won't sit too high.

cut, bent and welded in place......

panhard rod mount welded in its new position.

drain plug cut to be re positioned on the new bottom.

the old hole plugged.......

more pics to come as the build progresses.......