The whole process of fitting power windows to my 75 series ute was the simple fact that, I was sick of my knee hitting the window winder handle (crank) when driving.. In the bush its even worse. So the only remedy was electric.

But they dont make electric window regulators for 75 series as I know of.

Or if they do imagine the cost... 1 window motor from toyota is $900 .....crazy.....and you need 2 regulators aswell .( the mechanical bit).

Only other option is to buy a universal window kit. DONT BOTHER, BEEN THERE DONE THAT....DONT WORK REAL GOOD AT ALL.

So lets go the factory look.

WHAT YOU NEED TO DO FIRST BEFORE ANYTHING ELSE is go the the wreckers and get youreself, 2 front door, left & right electric window regulators with motors.

THESE MUST BE FROM A "TOYOTA".

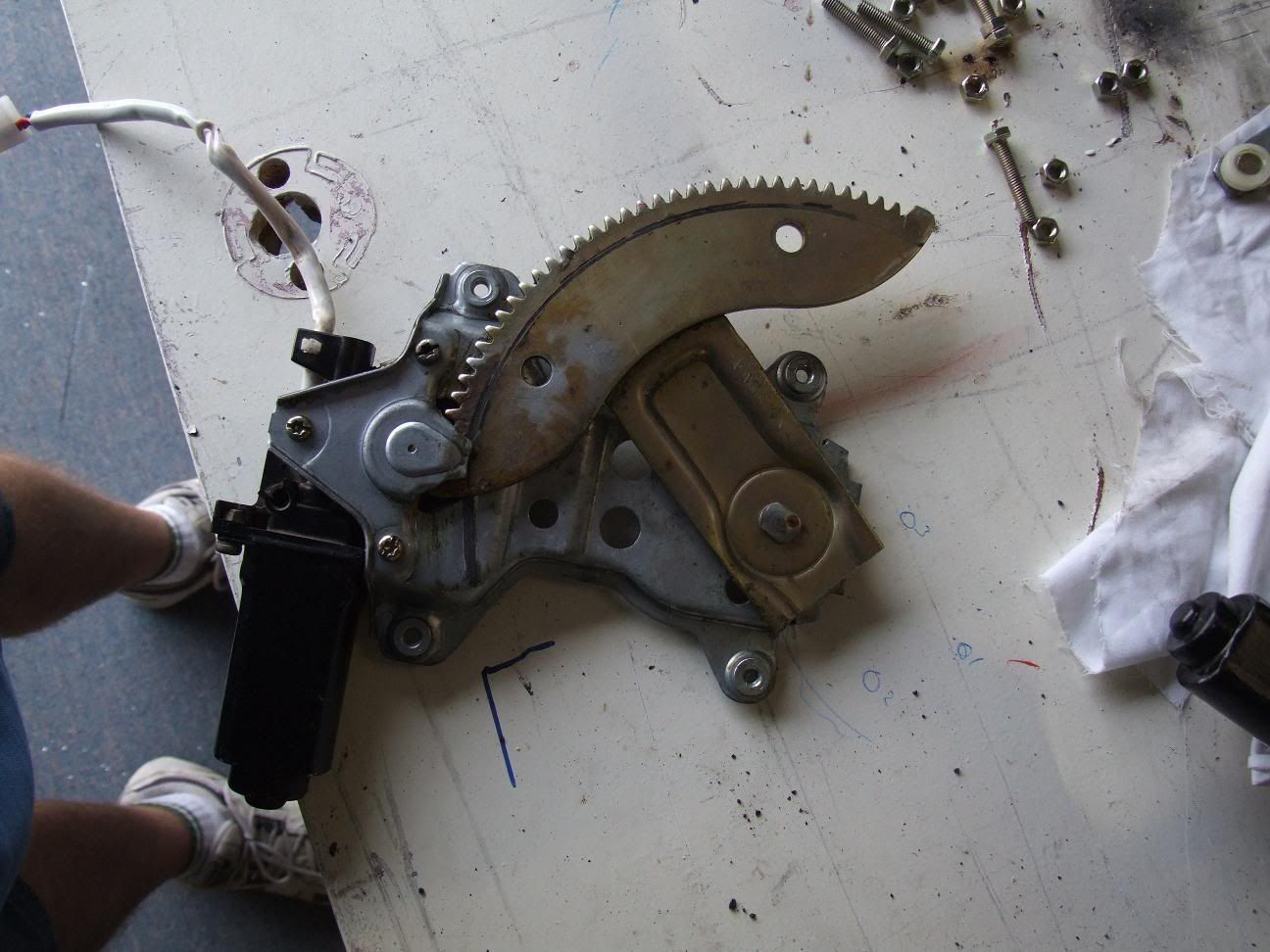

What model?....Camry, Cressida, Landcruiser...dosent matter.. as long as tthey look like the one below.....NON-Cable type.

These ones are the scissor type and are from a Toyota Cressida...and an old one at that.

I paid $80 for both... TEST the motors before leaving the wreckers so you know the motors are ok.

I had a look at alot of regulators whilst I was there and apart from the arms the motor and housings are all the same dimensions for mounting.

WHEN YOU HAVE 2 OF THESE LEFT & RIGHT THEN FOLLOW MY THREAD.